Toyota Sienna Service Manual: Evaporative Emission System

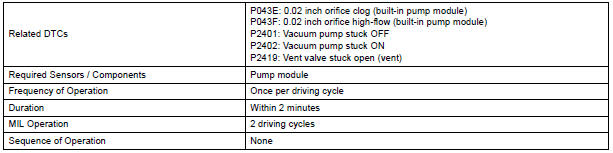

DTC P043E Evaporative Emission System Reference Orifice Clog Up

DTC P043F Evaporative Emission System Reference Orifice High Flow

DTC P2401 Evaporative Emission System Leak Detection Pump Control Circuit Low

DTC P2402 Evaporative Emission System Leak Detection Pump Control Circuit High

DTC P2419 Evaporative Emission System Switching Valve Control Circuit Low

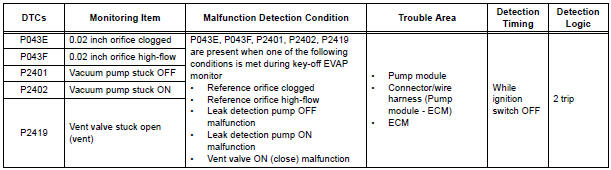

DTC SUMMARY

HINT: The 0.02 inch orifice is located inside the pump module.

DESCRIPTION

The circuit description can be found in the EVAP (Evaporative Emission) System.

INSPECTION PROCEDURE

Refer to the EVAP System.

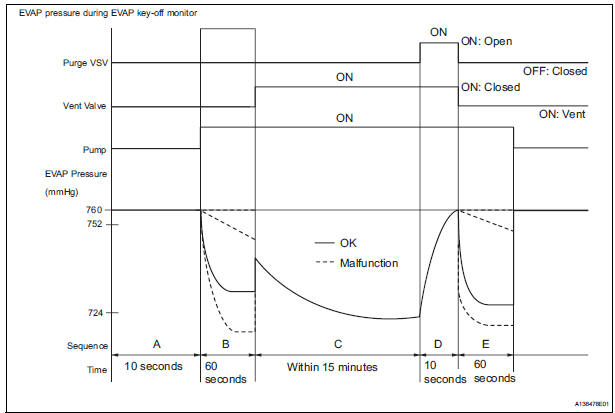

MONITOR DESCRIPTION

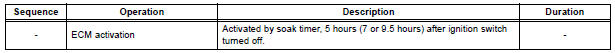

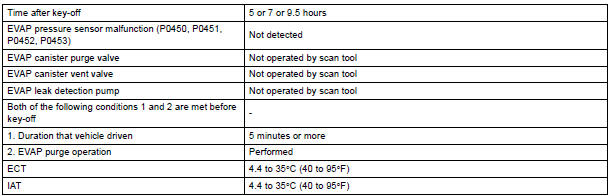

5 hours*1 after the ignition switch is turned off, the electric vacuum pump creates negative pressure (vacuum) in the EVAP (Evaporative Emission) system. The ECM monitors for leaks and actuator malfunctions based on the EVAP pressure.

HINT: *1: If the engine coolant temperature is not below 35C (95F) 5 hours after the ignition switch is turned off, the monitor check starts 2 hours later. If it is still not below 35C (95F) 7 hours after the ignition switch is turned off, the monitor check starts 2.5 hours later.

*2: If there is only a small amount of fuel in the fuel tank, stabilizing the EVAP pressure takes longer than usual.

The leak detection pump creates negative pressure through the reference orifice. When the system is normal, the EVAP pressure is in 724 to 752 mmHg* and saturated within a minute.

If not, the ECM interprets this as a malfunction. The ECM will illuminate the MIL and set DTC if this malfunction is detected in consecutive drive cycle.

*: Typical valve

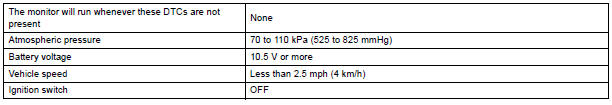

MONITOR STRATEGY

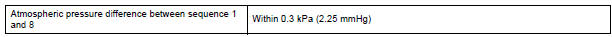

TYPICAL ENABLING CONDITIONS

Key-off monitor sequence 1 to 8

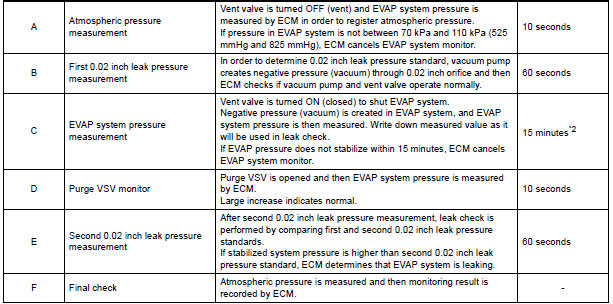

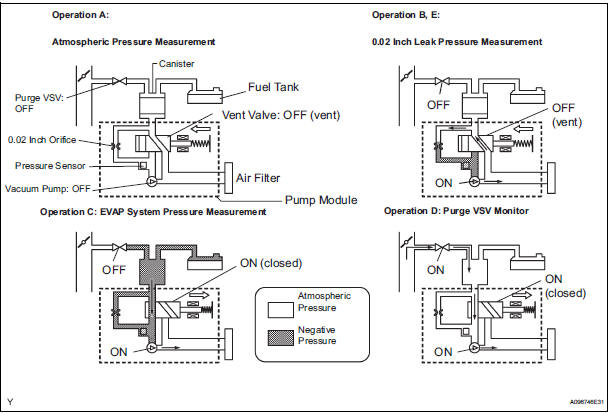

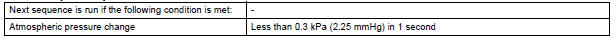

1. Atmospheric pressure measurement

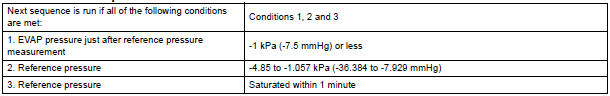

2. First reference pressure measurement

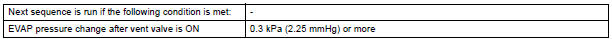

3. EVAP canister vent valve close stuck check

4. Vacuum introduction

5. EVAP canister purge valve close stuck check

6. Second reference pressure measurement

7. Leak check

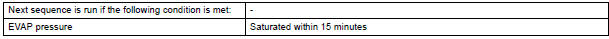

8. Atmospheric pressure measurement

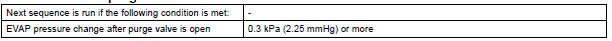

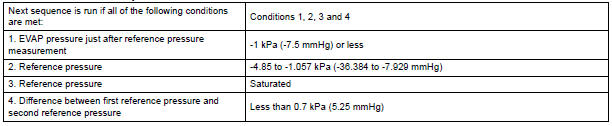

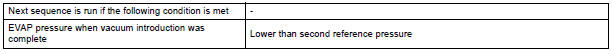

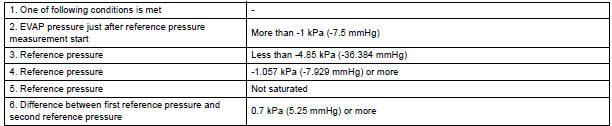

TYPICAL MALFUNCTION THRESHOLDS

MONITOR RESULT

Refer to CHECKING MONITOR STATUS

Catalyst System Efficiency Below Threshold

Catalyst System Efficiency Below Threshold

DTC P0420 Catalyst System Efficiency Below Threshold

(Bank 1)

DTC P0430 Catalyst System Efficiency Below Threshold

(Bank 2)

MONITOR DESCRIPTION

The ECM uses the sensors mounted in front of and be ...

Evaporative Emission Control System Incorrect

Purge Flow

Evaporative Emission Control System Incorrect

Purge Flow

DTC P0441 Evaporative Emission Control System Incorrect

Purge Flow

DTC SUMMARY

DESCRIPTION

The circuit description can be found in the EVAP (Evaporative Emission)

System.

INSPECTION PROCEDU ...

Other materials:

Rear view monitor

system

The rear view monitor system assists the driver by displaying an

image of the view behind the vehicle and guide lines while backing

up, for example while parking.

The screen illustrations used in this text are intended as examples,

and may differ from the image that is actually displayed on the

...

Parts location

HOW TO PROCEED WITH

TROUBLESHOOTING

1 VEHICLE BROUGHT TO WORKSHOP

2 CUSTOMER PROBLEM ANALYSIS

(a) Confirm problem symptoms.

3 CHECK AND CLEAR DTCS

4 PROBLEM SYMPTOM CONFIRMATION

5 SYMPTOM SIMULATION

6 DTC CHECK (OTHER THAN MULTIPLEX DTC)

7 DTC CHART

8 PROBLEM SYMP ...

Calibration

1. SELECT COMPASS DISPLAY MODE

The MODE switch allows you to select the Display

or Non-display mode of the compass.

HINT:

In compass display mode, the display indicates

outside temperature/average fuel consumption/

instantaneous fuel consumption/distance to empty

with compass.

2. ...