Toyota Sienna Service Manual: Front wheel alignment

Adjustment

NOTICE: For vehicles equipped with VSC, if wheel alignment has been adjusted, and if suspension or underbody components have been removed/installed or replaced, be sure to perform the following initialization procedure in order for the system to function normally: 1. Disconnect the negative battery terminal for more than 2 seconds.

2. Reconnect the negative battery terminal.

3. Perform zero point calibration of the yaw rate and acceleration sensor and test mode inspection.

HINT: (See page BC-70)

1. INSPECT TIRE

HINT: (See page TW-2)

2. MEASURE VEHICLE HEIGHT

(a) Bounce the vehicle at the corners up and down to stabilize the suspension and inspect the vehicle height.

Vehicle height:

FF

4WD

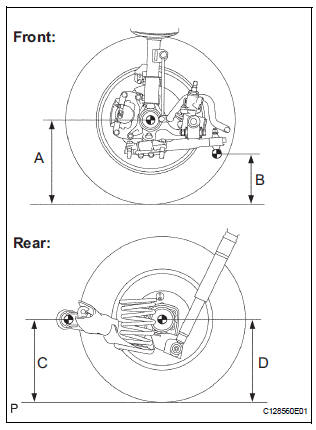

Measuring points: A: Ground clearance of front wheel center

B: Ground clearance of lower suspension arm No. 2 set bolt center

C: Ground clearance of rear axle carrier bushing set bolt center

D: Ground clearance of rear wheel center

NOTICE: Before inspecting the wheel alignment, adjust the vehicle height to the specified value.

HINT: If the vehicle height is not as specified, adjust it by pushing down or lifting the body.

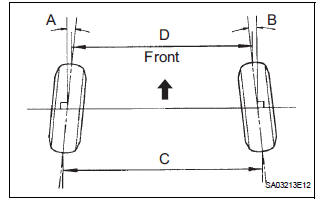

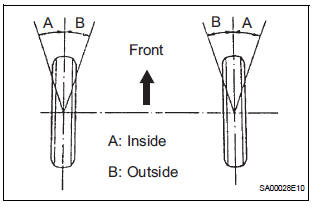

3. INSPECT TOE-IN

(a) Inspect the toe-in.

Toe-in

FF

4WD

HINT: If the toe-in is not within the specified value, adjust it at the rack ends.

4. ADJUST TOE-IN

(a) Remove the rack boot set clips.

(b) Loosen the tie rod end lock nuts.

(c) Turn the right and left rack ends by an equal amount to adjust the toe-in.

HINT: Adjust the toe-in to the center of the specified value as much as possible.

(d) Make sure that the lengths of the right and left rack ends are the same.

(e) Tighten the tie rod end lock nuts.

Torque: 74 N*m (755 kgf*cm, 55 ft.*lbf) (f) Place the boots on the seats and install the clips.

HINT: Make sure that the boots are not twisted.

5. INSPECT WHEEL ANGLE

(a) Turn the steering wheel fully and measure the turning angle.

Wheel turning angle:

FF

4WD

HINT: If the right and left inside wheel angles are not as specified, check the right and left rack end lengths.

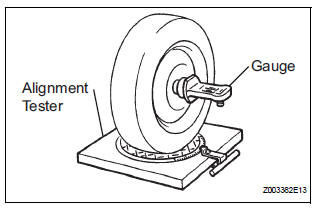

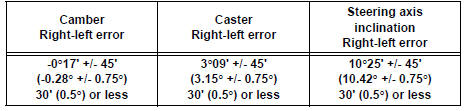

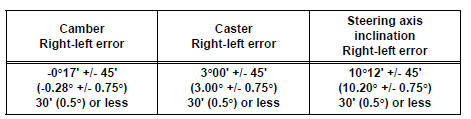

6. INSPECT CAMBER, CASTER AND STEERING AXIS INCLINATION

(a) Install the camber-caster-kingpin gauge or position the vehicle on the wheel alignment tester.

(b) Inspect the camber, caster and steering axis inclination.

FF

4WD

HINT: If the caster and steering axis inclination are not within the specified values, after the camber has been correctly adjusted, recheck the suspension parts for damaged and worn out parts.

7. ADJUST CAMBER

NOTICE: After the camber has been adjusted, inspect the toein.

(a) Remove the front wheel.

(b) Remove the 2 nuts on the lower side of the shock absorber. (Procedure "B")

NOTICE: When removing the nut, hold the bolt not to rotate.

(c) Clean the installation surfaces of the shock absorber and the steering knuckle.

(d) Temporarily install the 2 nuts.

(e) Adjust the camber by pushing or pulling the lower side of the shock absorber in the direction in which the camber adjustment is required.

(f) Tighten the nuts.

Torque: 210 N*m (2140 kgf*cm, 155 ft.*lbf)

NOTICE: When installing the nut, stop the bolt from rotating and tighten the nut.

(g) Install the front wheel.

Torque: 103 N*m (1050 kgf*cm, 76 ft.*lbf) (h) Check the camber.

HINT:

- Adjust the camber to the center of the specified value as much as possible.

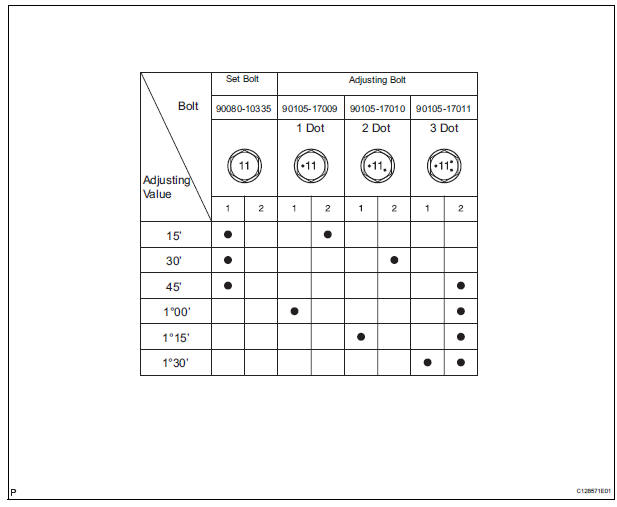

- Adjusting value for the set bolts is 6' to 30' (0.1° to 0.5°).

- If the camber is not within the specified value, using the following table, estimate how much additional camber adjustment will be required, and select the camber adjusting bolt.

NOTICE: Tighten the adjusting bolt with a washer and a new nut.

(i) Perform the procedure mentioned above again. At procedure "B", replace 1 or 2 selected bolts.

HINT: Replace one bolt at a time when replacing 2 bolts.

Suspension system

Suspension system

How to proceed with troubleshooting

HINT:

This is the repair procedure for vehicle pull.

Problem symptoms table

FRONT SUSPENSION SYSTEM

REAR SUSPENSION SYSTEM

...

Rear wheel alignment

Rear wheel alignment

ADJUSTMENT

NOTICE:

For vehicles equipped with VSC, if wheel alignment has

been adjusted, and if suspension or underbody

components have been removed/installed or replaced, be

sure to perform the ...

Other materials:

On-vehicle inspection

NOTICE:

In this section, the terms "cold" and "hot" refer to the

temperature of the coils. "Cold" means approximately -

10°C (14°F) to 50°C (122°F). "Hot" means approximately

50°C (122°F) to 100°C (212°F).

1. INSPECT IGNITION C ...

Room temperature sensor

On-vehicle inspection

1. INSPECT A/C ROOM TEMPERATURE SENSOR

(a) Remove the A/C room temperature sensor.

(b) Measure the resistance according to the value(s) in

the table below.

Standard resistance

NOTICE:

Even slightly touching the sensor may

change the resistance value. Be sure ...

Throttle Actuator Control Throttle Body Range / Performance

DESCRIPTION

The Electronic Throttle Control System (ETCS) is composed of the throttle

actuator, Throttle Position (TP)

sensor, Accelerator Pedal Position (APP) sensor, and ECM. The ECM operates the

throttle actuator to

regulate the throttle valve in response to driver inputs. The TP senso ...