Toyota Sienna Service Manual: How to proceed with troubleshooting

HINT: The intelligent tester can be used in steps 2, 3, 4, 6 and 9.

1 VEHICLE BROUGHT TO WORKSHOP

2 CONNECT INTELLIGENT TESTER TO DLC3

HINT: If the display indicates a communication fault in the tester, inspect the DLC3.

3 CHECK DTC AND FREEZE FRAME DATA

- Check for DTC(s) and freeze frame data.

HINT: Record or print the DTCs and freeze frame data, if necessary.

4 CLEAR DTC AND FREEZE FRAME DATA

- Clear the DTC(s) and freeze frame data

5 CONDUCT VISUAL INSPECTION

6 SET CHECK MODE DIAGNOSIS

- Set the check mode

7 CONFIRM PROBLEM SYMPTOMS

HINT: If the engine does not start, perform steps 9 and 11 first.

Result

8 SIMULATE SYMPTOMS

9 CHECK FOR DTCS

- Check for DTCs.

Result

10 REFER TO DTC CHART

HINT: Refer to the DTC chart

GO TO STEP 13

11 CONDUCT BASIC INSPECTION

HINT: Refer to "BASIC INSPECTION".

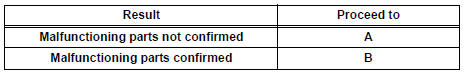

Result

12 REFER TO PROBLEM SYMPTOMS TABLE

HINT: Refer to "PROBLEM SYMPTOMS TABLE".

Result

13 CHECK ECM POWER SOURCE CIRCUIT

HINT: Refer to "ECM POWER SOURCE CIRCUIT"

14 CONDUCT CIRCUIT INSPECTION

Result

15 CHECK FOR INTERMITTENT PROBLEMS

HINT: Refer to "CHECK FOR INTERMITTENT PROBLEMS"

GO TO STEP 17

16 CONDUCT PARTS INSPECTION

17 IDENTIFY PROBLEM

18 ADJUST AND/OR REPAIR

19 CONDUCT CONFIRMATION TEST

END

Definition of terms

Definition of terms

Terms

Definitions

Monitor Description

Description of what ECM monitors and how to detect malfunctions

(monitoring purpose and details).

Related DTCs

A gro ...

Check for intermittent

problems

Check for intermittent

problems

1. CHECK FOR INTERMITTENT PROBLEMS

HINT:

For use of the intelligent tester only:

Inspect the vehicle's ECM using check mode.

Intermittent problems are easier to detect with an

intelligent teste ...

Other materials:

Engine coolant temperature sensor

COMPONENTS

REMOVAL

1. DRAIN ENGINE COOLANT (See page CO-6)

2. REMOVE V-BANK COVER SUB-ASSEMBLY (See

page EM-28)

3. REMOVE NO. 2 AIR CLEANER INLET (See page EM-

28)

4. REMOVE NO. 1 AIR CLEANER INLET (See page EM-

28)

5. REMOVE AIR CLEANER CAP SUB-ASSEMBLY (See

page ES-493)

6. REMOVE AI ...

Power slide door warning buzzer

INSPECTION

1. INSPECT POWER SLIDE DOOR WARNING BUZZER LH

Check the resistance of the buzzer.

Resistance

If the result is not as specified, replace the buzzer.

NOTICE:

The circuit that causes the buzzer to sound is

built into the slide door ECU, not around the

buzzer.

Direct ...

Pressure Control Solenoid "A" Performance (Shift Solenoid

Valve SL1)

SYSTEM DESCRIPTION

The ECM uses signals from the vehicle speed sensor to

detect the actual gear position (1st, 2nd, 3rd, 4th

or 5th gear).

Then the ECM compares the actual gear with the shift schedule in the ECM memory

to detect mechanical

problems of the shift solenoid valves, valve b ...