Toyota Sienna Service Manual: Definition of terms

|

Terms |

Definitions |

| Monitor Description | Description of what ECM monitors and how to detect malfunctions (monitoring purpose and details). |

| Related DTCs | A group of diagnostic trouble codes that are output by ECM based on the same malfunction detection logic. |

| Typical Enabling Conditions | Preconditions that allow ECM to detect malfunction.

With all preconditions satisfied, ECM sets DTC when monitored value(s) exceeds malfunction threshold(s). |

| Sequence of Operation | Order of monitor priority, applied if multiple sensors and

components are involved in single malfunction detection

process.

Each sensor and component monitored in turn and not monitored until previous detection operation is completed |

| Required Sensors / Components | Sensors and components used by ECM to detect each malfunction |

| Frequency of Operation | Number of times ECM checks for each malfunction during each driving

cycle.

"Once per driving cycle" means ECM performs checks for that malfunction only once in single driving cycle. "Continuous" means ECM performs checks for that malfunction whenever enabling conditions are met. |

| Duration | Minimum time for which ECM must detect continuous deviation in monitored value(s) in order to set DTC. Timing begins when typical enabling conditions are met. |

| Malfunction Thresholds | Values, beyond which, ECM determines malfunctions exist and sets DTCs. |

| MIL Operation | Timing of MIL illumination after defect is detected.

"Immediate" means ECM illuminates MIL as soon as malfunction is detected. "2 driving cycles" means ECM illuminates MIL if the same malfunction is detected twice during the next sequential driving cycle. |

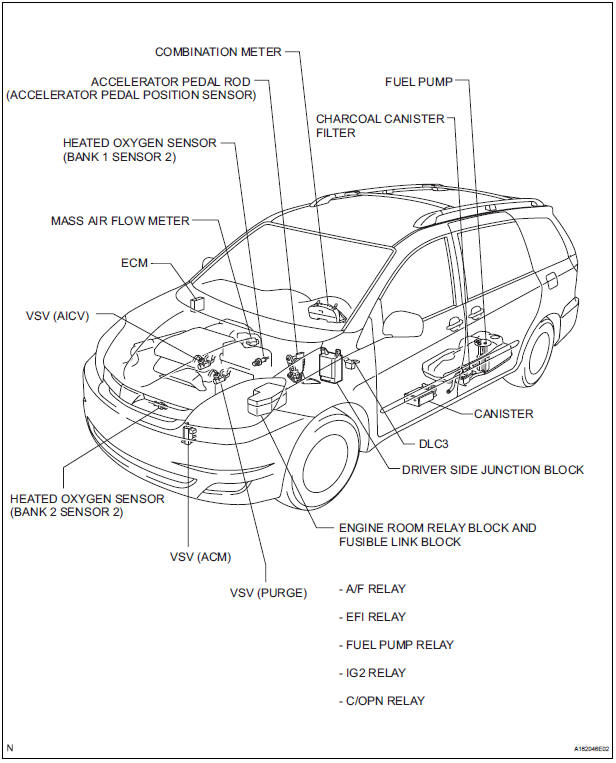

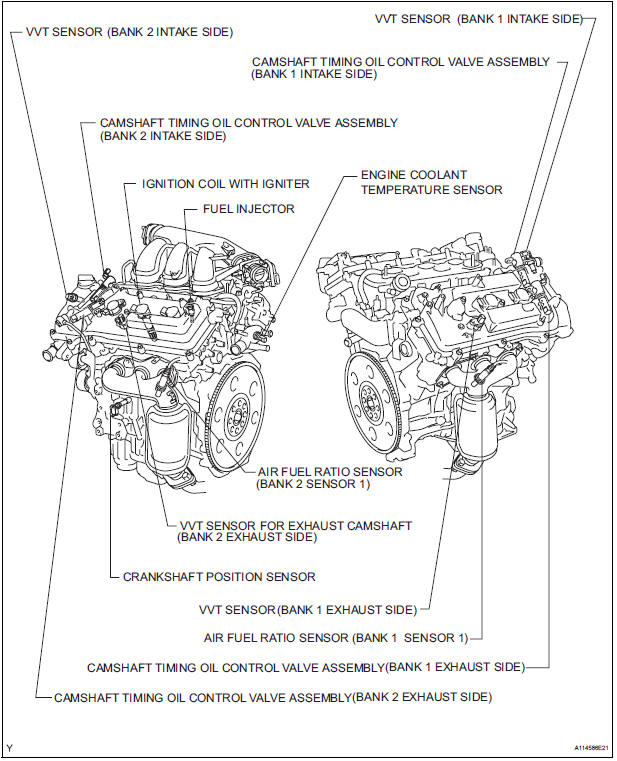

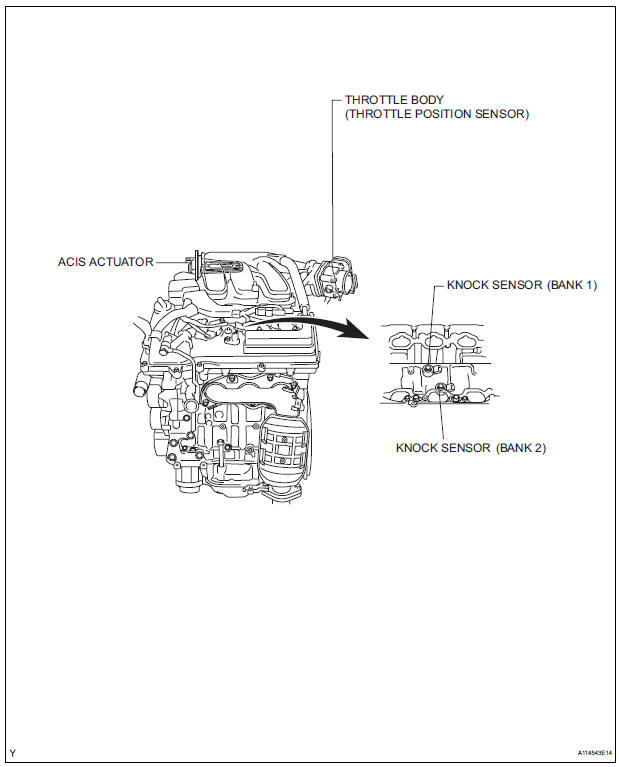

PARTS LOCATION

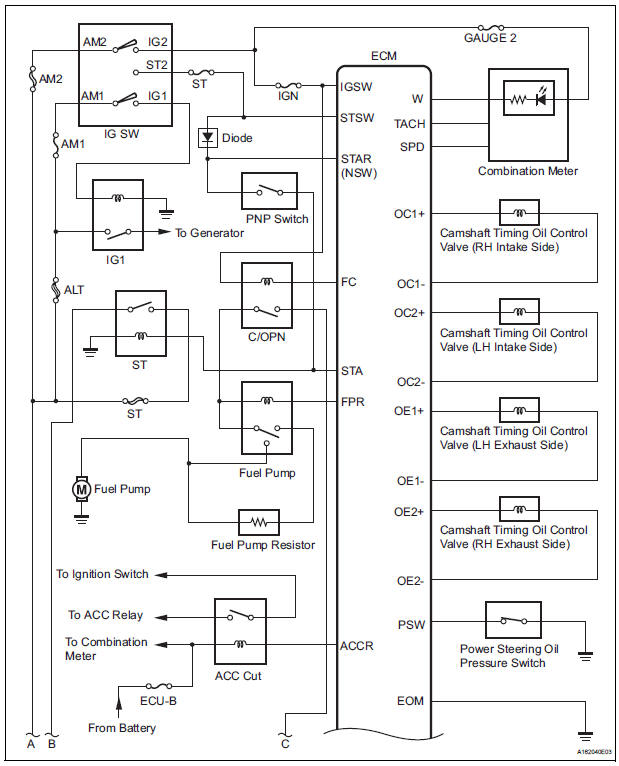

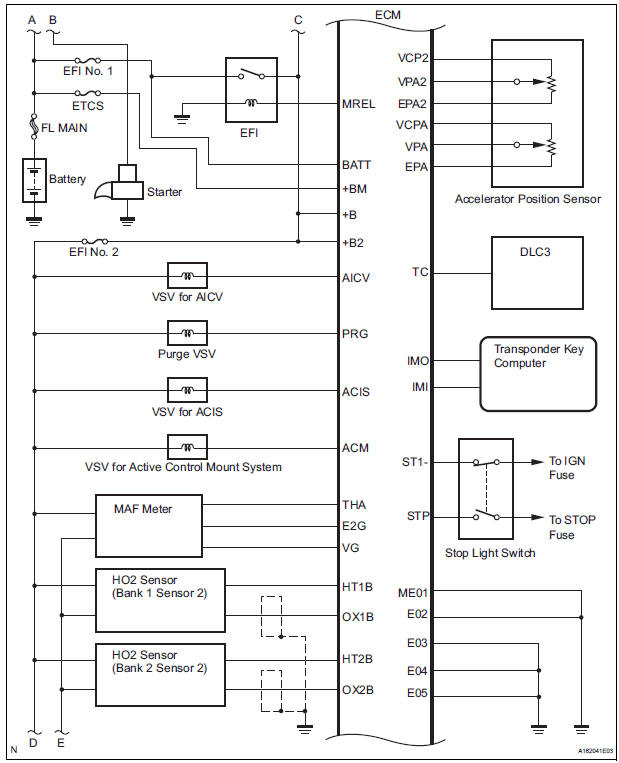

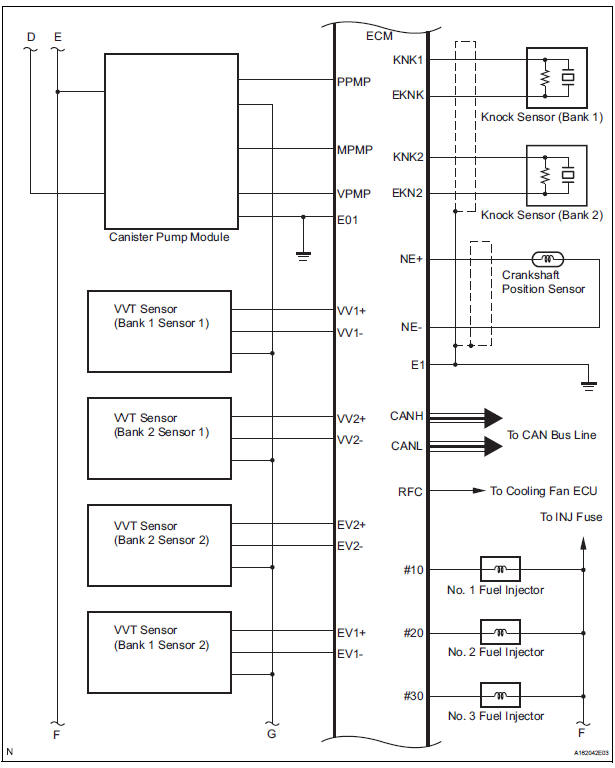

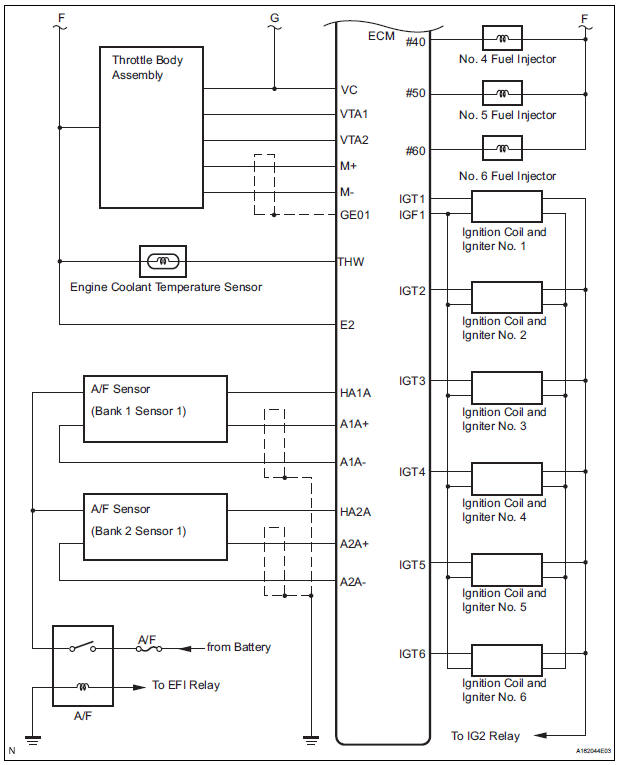

SYSTEM DIAGRAM

Precaution

Precaution

1. INITIALIZATION

NOTICE:

Perform RESET MEMORY (AT initialization) when

replacing the automatic transaxle assembly, engine

assembly or ECM.

Perform REGISTRATION (VIN registratio ...

How to proceed with

troubleshooting

How to proceed with

troubleshooting

HINT:

The intelligent tester can be used in steps 2, 3, 4, 6 and 9.

1 VEHICLE BROUGHT TO WORKSHOP

2 CONNECT INTELLIGENT TESTER TO DLC3

HINT:

If the display indicates a communication fault in the ...

Other materials:

Rear Air Outlet Damper Position Sensor Circuit

DESCRIPTION

This sensor detects the position of the rear air outlet control servo motor

and sends the appropriate

signals to the A/C amplifier. The position sensor is built in the rear air

outlet control servo motor.

The position sensor's resistance changes as the rear air outlet contro ...

Disassembly

1. REMOVE REAR NO. 2 SEAT COVER BEZEL

Remove the 3 screws.

Disengage the 3 claws and remove the rear No. 2

seat cover bezel.

2. REMOVE REAR SEAT RECLINING COVER RH

Remove the 2 screws.

Disengage the claw and remove the rear seat

reclining cover RH.

...

How to scroll

: Select to scroll to the next

or previous page.

: If

appears to the right of

titles, the complete titles are

too long for the display. Select

this button to scroll the title.

Turn the ÔÇťTUNEÔÇóSCROLLÔÇŁ knob

to move the cursor box to select a

desired item from the list, and

press ...