Toyota Sienna Service Manual: Inspection

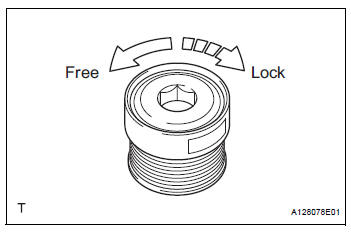

1. Inspect generator clutch pulley

(a) Hold the center of the pulley, and confirm that the outer ring turns counterclockwise and does not turn clockwise.

If the result is not as specified, replace the clutch pulley.

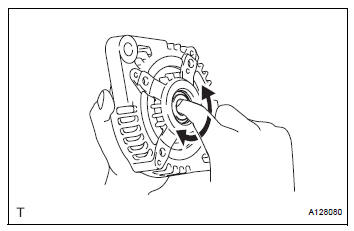

2. Remove generator drive end frame bearing

(a) Check that the bearing is not rough or worn.V

Ok: the bearing rotates smoothly.

If the bearing does not rotate smoothly, replace the bearing.

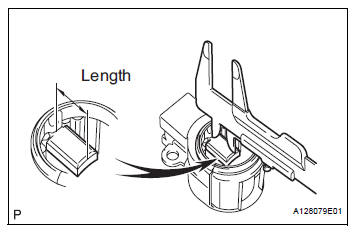

3. Inspect generator brush holder assembly

(a) Using vernier calipers, measure the length of the exposed brushes.

Standard exposed length: 9.5 to 11.5 mm (0.374 to 0.453 in.) Minimum exposed length: 4.5 mm (0.177 in.) If the exposed length is less than the minimum, replace the brush holder assembly.

4. INSPECT GENERATOR ROTOR ASSEMBLY

(a) Check that the generator rotor bearing is not rough or worn.

If necessary, replace the generator rotor assembly.

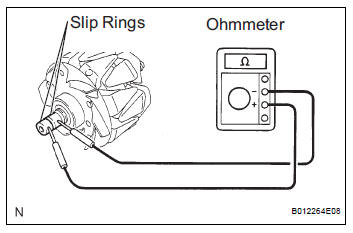

(b) Check the generator rotor for an open circuit.

(1) Using an ohmmeter, measure the resistance between the slip rings.

Standard resistance

If the result is not as specified, replace the generator rotor assembly.

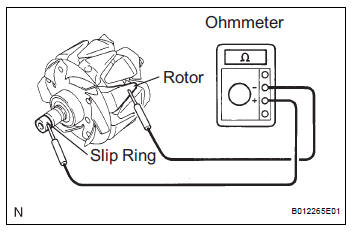

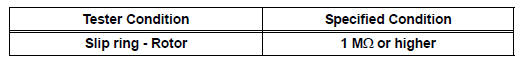

(c) Check the rotor for a short to ground.

(1) Using an ohmmeter, measure the resistance between the slip ring and rotor.

Standard resistance

If the result is not as specified, replace the generator rotor assembly.

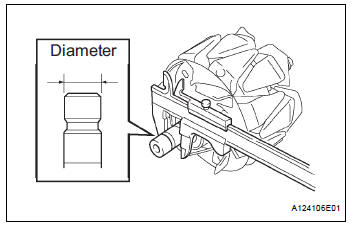

(d) Using vernier calipers, measure the slip ring diameter.

Standard diameter: 14.2 to 14.4 mm (0.559 to 0.567 in.) Minimum diameter: 14.0 mm (0.551 in.)

If the diameter is less than the minimum, replace the generator rotor assembly.

Disassembly

Disassembly

1. REMOVE GENERATOR CLUTCH PULLEY

(A) using a screwdriver, remove the generator pulley

cap.

(b) Set SST (A) and (B).

SST 09820-63020

(c) Clamp SST (A) in a vise.

NOTICE:

...

Replacement

Replacement

1. REPLACE GENERATOR DRIVE END FRAME BEARING

(a) Remove the 4 screws and retainer plate from the

drive end frame.

(b) Using SST and a hammer, tap out the drive end

frame bearing from the d ...

Other materials:

Vanity light

ON-VEHICLE INSPECTION

1. LH VISOR ASSEMBLY

Inspect vanity light resistance.

check that the resistance exists between the

terminal 1 and the terminal 2 when the light is

operated.

Resistance:

OFF (closed):

10 kΩ or higher

ON (opened):

Below 1 Ω

2. RH VISOR ...

Check and replace ecu

NOTICE: • The connector should not be disconnected from

the ECU. Perform the inspection from the

backside of the connector on the wire harness

side.

• When no measuring condition is specified,

perform the inspection with the engine stopped

and the ignition switch on.

• Che ...

Short in CAN Bus Lines

DESCRIPTION

The CAN bus wires are considered to be shorted when the resistance between

terminals 6 (CANH) and

14 (CANL) of the DLC3 is below 54 Ω.

Symptom

Trouble Area

Resistance between terminals 6 (CANH) and 14 (CANL) of the DLC3

is below 54 Ω.

...