Toyota Sienna Service Manual: Inspection

1. INSPECT WINDSHIELD WIPER MOTOR ASSEMBLY

- LO Operation Check

- Connect the battery (+) to the terminal 1 (+1) of the connector, the battery (-) to the terminal 5 (E) of the connector, and check that the motor operates at low speed (LO).

- HI Operation Check

- Connect the battery (+) to the terminal 4 (+2) of the connector, the battery (-) to the terminal 5 (E) of the connector, and check that the motor operates at high speed (HI).

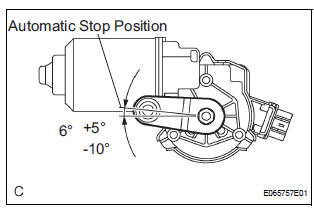

- Automatic Stop Operation Check

- Connect the battery (+) to the terminal 1 (+1) of the connector, the battery (-) to the terminal 5 (E) of the connector. With the motor being rotated at low speed (LO), disconnect terminal 1 (+1) to stop the wiper motor operation at any position except the automatic stop position.

- Using SST, connect the terminal 1 (+1) and 3

(S), and the battery (+) to the terminal 2 (B) to

restart the motor operation at low speed (LO).

SST 09843-18040

- Check the automatic stop position.

Standard: See the illustration.

Removal

Removal

1. REMOVE FRONT WIPER ARM HEAD CAP

Using a small screwdriver, remove the 2 front wiper

arm covers.

HINT:

Tape up the screwdriver tip before use.

2. REMOVE FR WIPER ARM RH

&nbs ...

Installation

Installation

1. INSTALL WINDSHIELD WIPER MOTOR ASSEMBLY

Apply MP grease to the crank arm pivot of the

windshield wiper motor assembly.

Install the windshield wiper motor assembly with the

...

Other materials:

Removal

1. Remove rear wheel

2. Remove exhaust pipe assembly

Hint:

(see page ex-8)

3. Remove propeller with center bearing

shaft assembly

Hint:

(see page pr-3)

4. REMOVE REAR DIFFERENTIAL FILLER PLUG

(A) using a hexagon wrench (10 mm), remove the filler

plug and gasket.

5. Remove rear differentia ...

Installation

HINT:

Use the same procedures for the RH side and LH side.

The procedures listed below are for the LH side.

1. INSTALL CURTAIN SHIELD AIRBAG ASSEMBLY LH

Install the curtain shield airbag assembly LH with

the 13 bolts in the order shown in the illustration.

Torque: 14 N*m ...

Locking and unlocking the back door

Entry function (vehicles with a smart key system)

Carry the electronic key to enable this function.

Press the unlock button to

unlock all the doors.

The door cannot be unlocked for

3 seconds after the door is

locked.

Lock the back door again when

you leave the vehicle. The back

...