Toyota Sienna Service Manual: Removal

1. REMOVE FRONT WIPER ARM HEAD CAP

- Using a small screwdriver, remove the 2 front wiper arm covers.

HINT: Tape up the screwdriver tip before use.

2. REMOVE FR WIPER ARM RH

- Operate the wiper, and stop the windshield wiper motor assembly to the automatic stop position.

- Remove the nut and the FR wiper arm RH.

3. REMOVE FR WIPER ARM LH

- Remove the nut and the FR wiper arm LH.

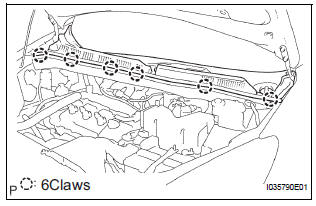

4. REMOVE COWL TOP VENTILATOR LOUVER SUBASSEMBLY

- Remove the 6 claws and the cowl top ventilator louver sub-assembly.

5. REMOVE WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY

- Disconnect the connector.

- Remove the 4 bolts and wiper motor & link assembly.

6. REMOVE WINDSHIELD WIPER MOTOR ASSEMBLY

- Using a screwdriver, disengage the meshing of rod at the crank arm pivot of the windshield wiper motor assembly.

- Remove the 3 bolts and windshield wiper motor assembly from the windshield wiper link assembly.

HINT: Turning the crank arm by hand prior to the operation will be able to remove the wiper motor easier.

Front wiper motor

Front wiper motor

COMPONENTS

...

Inspection

Inspection

1. INSPECT WINDSHIELD WIPER MOTOR ASSEMBLY

LO Operation Check

Connect the battery (+) to the terminal 1 (+1) of

the connector, the battery (-) to the terminal 5

(E) of th ...

Other materials:

Disassembly

1. REMOVE FRONT SEAT SIDE TABLE LEG COVER (w/

Table)

Using a screwdriver, disengage the claws and

remove the seat side table leg cover.

HINT:

Tape the screwdriver tip before use.

2. REMOVE FRONT SEAT SIDE TABLE (w/ Table)

Remove the 4 nuts and seat side table.

Rem ...

On-vehicle inspection

1. INSPECT BACK WINDOW (DEFOGGER WIRE)

NOTICE:

When cleaning the glass, wipe the glass along the

wire using a soft and dry cloth. Take care not to

damage the wires.

Do not use detergents or glass cleaners including

abrasive ingredients.

When measuring voltage, wr ...

How to proceed with

troubleshooting

HINT:

Troubleshoot in accordance with the procedures on the

following pages.

1 VEHICLE BROUGHT TO WORKSHOP

2 DTC CHECK

Check for DTCs and make a note of the code that is

output (See page MP-14).

Delete the DTC.

Check if the DTC is output once again when the problem

symptom is simulat ...