Toyota Sienna Service Manual: Installation

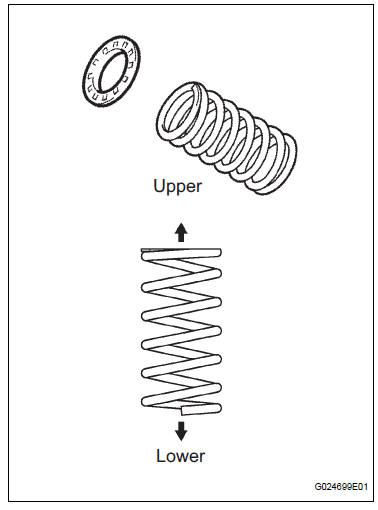

1. INSTALL REAR COIL SPRING INSULATOR UPPER LH

(a) Install the insulator upper LH to the coil spring rear LH.

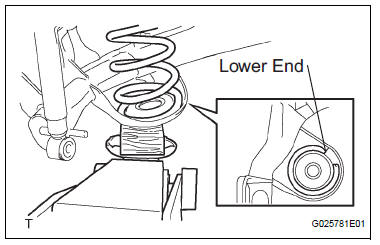

2. INSTALL COIL SPRING REAR LH

(a) Apply a shop rug to the rear axle beam assembly.

(b) Install the coil spring rear LH to the rear axle beam assembly.

HINT: Fit the lower end of the coil spring into the gap of the spring lower seat.

(c) Apply a shop rug to the rear axle beam assembly.

3. CONNECT SHOCK ABSORBER ASSEMBLY REAR LH

(a) While raising the jack, connect the shock absorber assembly rear LH to the rear axle beam assembly.

(b) Temporarily tighten the nut.

4. CONNECT SHOCK ABSORBER ASSEMBLY REAR RH

HINT: Connect the RH side by the same procedures as the LH side.

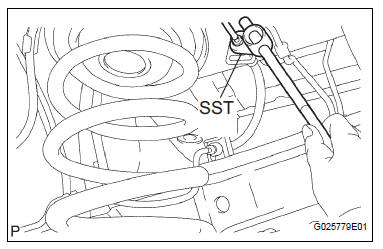

5. CONNECT REAR BRAKE TUBE NO.2

(a) Install the flexible hose and clip.

(b) Using SST, connect the brake tube to the flexible hose.

Torque: 15 N*m (153 kgf*cm, 11 ft.*lbf) SST 09023-00101

(c) Install the bolt.

Torque: 8.0 N*m (82 kgf*cm, 71 in.*lbf)

6. CONNECT REAR BRAKE TUBE NO.1 SST 09023-00101

HINT: Connect the RH side by the same procedures as the LH side.

7. INSTALL PARKING BRAKE CABLE ASSEMBLY NO.3

(a) Install the 2 bolts and parking brake cable assembly No.3 to the rear axle beam assembly.

Torque: 8.0 N*m (82 kgf*cm, 71 in.*lbf)

8. INSTALL PARKING BRAKE CABLE ASSEMBLY NO.2

HINT: Install the RH side by same procedures as the LH side.

9. INSTALL DIFFERENTIAL CARRIER ASSEMBLY REAR (for 4WD)

HINT: (See page DF-8)

10. INSTALL REAR DRIVE SHAFT ASSEMBLY LH (for 4WD)

(a) Install the rear drive shaft assembly LH, 4 washers and 4 nuts.

Torque: 56 N*m (571 kgf*cm, 41 ft.*lbf)

11. INSTALL REAR DRIVE SHAFT ASSEMBLY RH (for 4WD)

HINT: Install the RH side by same procedures as the LH side.

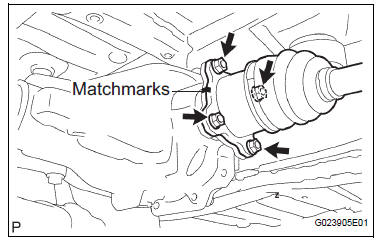

12. INSTALL PROPELLER W/CENTER BEARING SHAFT ASSEMBLY (for 4WD)

HINT: (See page PR-2)

13. INSTALL SPEED SENSOR REAR LH (for 4WD)

(a) Install the speed sensor rear LH and bolt.

Torque: 8.0 N*m (82 kgf*cm, 71 in.*lbf)

14. INSTALL SPEED SENSOR REAR RH (for 4WD)

HINT: Install the RH side by same procedures as the LH side.

15. CONNECT SKID CONTROL SENSOR WIRE (for 2WD)

(a) Connect the skid control sensor connector.

(b) Install the bolt and bracket to the rear axle beam assembly.

Torque: 8.0 N*m (82 kgf*cm, 71 in.*lbf)

HINT: Connect the RH side by same procedures with the LH side.

16. INSTALL EXHAUST PIPE ASSEMBLY TAIL

HINT:

- 2WD DRIVE TYPE (See page EX-2)

- 4WD DRIVE TYPE (See page EX-12)

17. BLEED BRAKE LINE

18. INSPECT BRAKE FLUID LEVEL IN RESERVOIR

19. STABILIZE SUSPENSION

(a) Install the rear wheel and jack down the vehicle.

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf) (b) Bounce the vehicle up and down several times to stabilize the suspension.

20. FULLY TIGHTEN SHOCK ABSORBER ASSEMBLY REAR LH

(a) Stabilize the shock absorber assembly rear LH.

If it is impossible to tighten the nut at this position, support the rear axle beam assembly with a jack and load the rear compartment with a mass of approximately 90 kg (198 lb).

Length of shock absorber: 2WD DRIVE TYPE: 234 mm (9.2 in.) 4WD DRIVE TYPE: 258 mm (10.2 in.)

(b) Fully tighten the nut.

Torque: 115 N*m (1,173 kgf*cm, 85 ft.*lbf)

21. FULLY TIGHTEN SHOCK ABSORBER ASSEMBLY REAR RH

HINT: Fully tighten the RH side by same procedures as the LH side.

22. FULLY TIGHTEN REAR AXLE BEAM ASSEMBLY

(a) Stabilize the rear axle beam assembly.

(b) Fully tighten the bolt.

Torque: 135 N*m (1,377 kgf*cm, 100 ft.*lbf)

NOTICE:

- Tighten the bolt and not the nut.

- The vehicle height should be the same as the height that the shock absorber is fully tightened.

HINT: Fully tighten the RH side by same procedures as the LH side.

23. INSTALL REAR FLOOR NO.2 CROSSMEMBER BRACE LH

(a) Install the floor No.2 crossmember brace and 2 bolts.

Torque: 28 N*m (286 kgf*cm, 21 ft.*lbf)

24. INSTALL REAR FLOOR NO.2 CROSSMEMBER BRACE RH

HINT: Install the RH side by the same procedures as the LH side.

25. INSTALL FUEL TANK FILLER HOSE COVER

(a) Install the fuel tank filler pipe protector, 2 bolts, 3 screws and 3 nuts.

(b) Install the fuel tank filler hose cover and 3 bolts.

Torque: 5.0 N*m (51 kgf*cm, 44 in.*lbf)

26. INSPECT REAR WHEEL ALIGNMENT

HINT: (See page SP-9)

27. CHECK ABS SPEED SENSOR SIGNAL

(a) ABS WITH EBD SYSTEM (See page BC-2) (b) ABS WITH EBD & BA & TRAC & VSC SYSTEM (See page BC-68)

Removal

Removal

1. REMOVE REAR WHEEL

2. REMOVE SKID CONTROL SENSOR WIRE (for 2WD)

(a) Disconnect the skid control sensor connector.

(b) Remove the bolt and disconnect the bracket from

the rear axle beam assembl ...

Rear shock absorber

Rear shock absorber

COMPONENTS

...

Other materials:

Removal

1. REMOVE FRONT WHEELS

2. REMOVE FRONT STABILIZER LINK ASSEMBLY LH

(a) Remove the 2 nuts and front stabilizer link assembly

LH.

HINT:

If the ball joint turns together with the nut, use a

hexagon (6 mm) wrench to hold the stud.

3. REMOVE FRONT STABILIZER LINK ASSEMBLY RH

HINT:

Remove the ...

Freeze frame data

1. FREEZE FRAME DATA

(a) The vehicle (sensor) status, stored during ABS and/

or VSC operation or at the time of an error code

detection, can be displayed by the intelligent tester.

(b) Only one record of freeze frame data is stored and

the freeze frame data generated during ABS and/or

VSC op ...

Installation

1. INSTALL BRAKE ACTUATOR

(a) Install the brake actuator assembly with the 2 nuts.

Torque: 5.4 N*m (55 kgf*cm, 48 in.*lbf)

2. INSTALL BRAKE ACTUATOR WITH BRACKET

(a) Install the actuator with bracket with the 3 bolts.

Torque: 20 N*m (199 kgf*cm, 14 ft.*lbf)

NOTICE:

Be careful not to dam ...