Toyota Sienna Service Manual: Removal

1. REMOVE REAR WHEEL

2. REMOVE SKID CONTROL SENSOR WIRE (for 2WD)

(a) Disconnect the skid control sensor connector.

(b) Remove the bolt and disconnect the bracket from the rear axle beam assembly.

HINT: Separate the RH side by the same procedures as the LH side.

3. SEPARATE SPEED SENSOR REAR LH (for 4WD)

(a) Remove the bolt and speed sensor rear LH.

4. SEPARATE SPEED SENSOR REAR RH (for 4WD)

HINT: Separate the RH side by the same procedures as the LH side.

5. REMOVE EXHAUST PIPE ASSEMBLY TAIL

HINT:

- 2WD DRIVE TYPE (See page EX-2)

- 4WD DRIVE TYPE (See page EX-8)

6. REMOVE PROPELLER W/CENTER BEARING SHAFT ASSEMBLY (for 4WD)

HINT: (See page PR-2)

7. SEPARATE REAR DRIVE SHAFT ASSEMBLY LH (for 4WD)

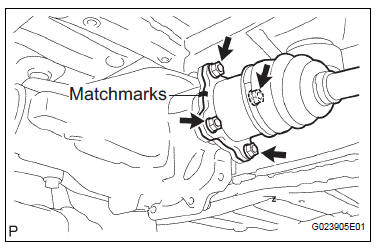

(a) Place matchmarks on the rear drive shaft assembly LH and differential flange.

(b) Remove the 4 nuts and 4 washers, separate rear drive shaft assembly LH.

8. SEPARATE REAR DRIVE SHAFT ASSEMBLY RH (for 4WD)

HINT: Separate the RH side by the same procedures as the LH side.

9. REMOVE DIFFERENTIAL CARRIER ASSEMBLY REAR (for 4WD)

HINT: (See page DF-8)

10. SEPARATE PARKING BRAKE CABLE ASSEMBLY NO.3

(a) Remove the 2 bolts and parking brake cable assembly No.3.

11. SEPARATE PARKING BRAKE CABLE ASSEMBLY NO.2

HINT: Separate the RH side by the same procedures as the LH side.

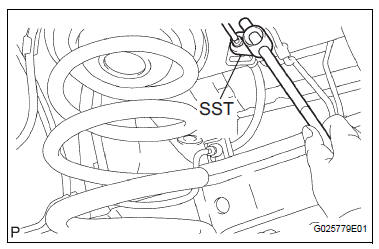

12. SEPARATE REAR BRAKE TUBE NO.2

(a) Using SST, separate the brake tube from the flexible hose. Catch the brake fluid with a container as it drains out.

SST 09023-00101

(b) Remove the clip, and separate the flexible hose.

(c) Remove the bolt and separate the brake tube from rear axle beam assembly.

13. SEPARATE REAR BRAKE TUBE NO.1

SST 09023-00101

HINT: Separate the RH side by the same procedures as the LH side.

14. REMOVE FUEL TANK FILLER HOSE COVER

(a) Remove the 2 bolts, 3 screws, 3 nuts and fuel tank filler pipe protector.

(b) Remove the 3 bolts and fuel tank filler hose cover.

15. REMOVE REAR FLOOR NO.2 CROSSMEMBER BRACE LH

(a) Remove the 2 bolts and floor No.2 crossmember brace.

16. REMOVE REAR FLOOR NO.2 CROSSMEMBER BRACE RH

HINT: Remove the RH side by the same procedures as the LH side.

17. LOOSEN REAR AXLE BEAM ASSEMBLY

(a) Refer to hint below.

HINT: Loosen the RH side by the same procedures as the LH side.

NOTICE:

- When loosening the bolt, hold the nut not to rotate.

- Do not remove the bolt and nut.

18. SEPARATE SHOCK ABSORBER ASSEMBLY REAR LH

(a) Support the rear axle beam assembly with a jack.

(b) Remove the bolt and separate the shock absorber assembly rear LH.

19. SEPARATE SHOCK ABSORBER ASSEMBLY REAR RH

HINT: Separate the RH side by the same procedures as the LH side.

20. REMOVE COIL SPRING REAR LH

(a) Apply a shop rug between the coil spring rear LH and rear axle beam assembly.

(b) Apply a shop rug between the coil spring rear RH and rear axle beam assembly.

(c) Remove the coil spring LH by slowly lowering the jack.

21. REMOVE REAR COIL SPRING INSULATOR UPPER LH

(a) Remove the rear coil spring insulator upper LH from the coil spring rear LH.

Rear coil spring

Rear coil spring

COMPONENTS

...

Installation

Installation

1. INSTALL REAR COIL SPRING INSULATOR UPPER LH

(a) Install the insulator upper LH to the coil spring rear

LH.

2. INSTALL COIL SPRING REAR LH

(a) Apply a shop rug to the rear axle beam asse ...

Other materials:

Optimal use of the audio

system

On the ŌĆ£Sound SettingsŌĆØ screen, sound quality (Treble/Mid/

Bass), volume balance can be adjusted.

How to adjust the sound settings and sound quality

1, 2, 3 Select ŌĆ£-ŌĆØ or ŌĆ£+ŌĆØ to adjust

the treble, mid or bass to

a level between -5 and 5.

4, 5 Select ŌĆ£FrontŌĆØ or ŌĆ£RearŌĆØ ...

ŌĆ£Contact/Call History SettingsŌĆØ screen

Display the ŌĆ£Phone/Message SettingsŌĆØ screen.

Select ŌĆ£Contact/Call History SettingsŌĆØ.

Select the desired item to be set.

For PBAP compatible

Bluetooth® phones, select to

set ŌĆ£Automatic TransferŌĆØ on/

off. When set to on, the

phoneŌĆÖs contact data and history

a ...

Removal

1. DISCHARGE FUEL SYSTEM PRESSURE

HINT:

See page FU-1.

2. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

3. REMOVE NO. 1 ENGINE UNDER COVER

4. DRAIN ENGINE COOLANT (See page CO-6)

5. REMOVE FRONT WIPER ARM HEAD CAP (See page

WW-4)

6. REMOVE FRONT WIPER ARM RH (See page WW-4)

7. REMOVE FRO ...