Toyota Sienna Service Manual: Installation

1. INSTALL TIRE PRESSURE WARNING VALVE AND TRANSMITTER

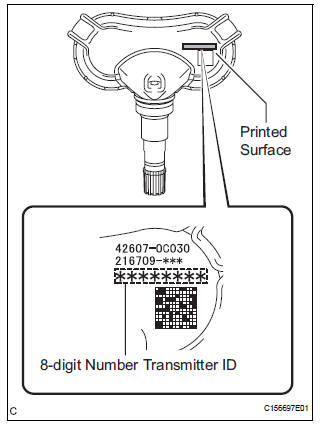

(a) Insert the tire pressure warning valve and transmitter into the valve installation hole. Insert it from the inside of the rim so that the printed surface can be seen.

NOTICE:

- Check that there is no visible deformation, damage, or other abnormalities on the tire pressure warning valve and transmitter.

- Check that there is no foreign matter on the inner grommet and around the rim hole.

- If the tire pressure warning valve and transmitter is installed upside down, it may be damaged or fail to transmit signals when running at high speeds.

- If installing a new tire pressure warning valve and transmitter, write down the ID number before installation.

- It is necessary to register the ID in the ECU after installation (See page TW-20).

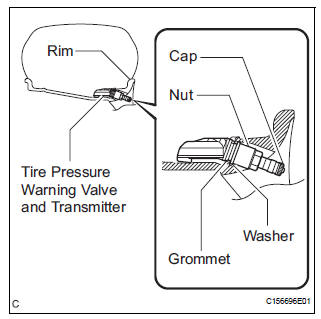

(b) Install the washer on the tire pressure warning valve and transmitter from the rim side and tighten the nut.

Torque: 4.0 N*m (41 kgf*cm, 35 in.*lbf)

NOTICE:

- No further tightening is required once the nut is tightened to the specified torque.

- Check that there is no foreign matter on the washer and nut.

- If replacing the tire pressure warning valve and transmitter, make sure that the new grommet, washer, and nut are used.

- Check that there is no oil, water, or lubricant

around the rim hole, tire pressure warning

valve and transmitter, washer, and nut.

Failing to do so may result in improper installation.

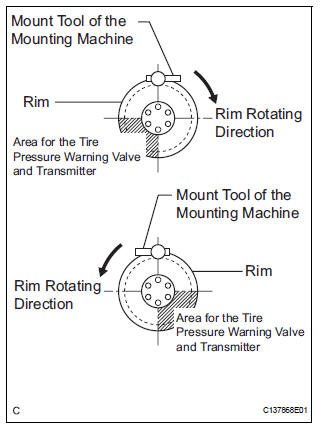

(c) Set the wheel disc to the mounting machine and install the lower tire bead. Position the main body of the tire pressure warning valve and transmitter in the shaded area shown in the illustration.

NOTICE:

- If the tire pressure warning valve and transmitter is positioned outside this area, it will be interfered with the tire bead, and may cause damage to the tire pressure warning valve and transmitter.

- If the use of lubricant is required when installing the bead, do not apply the lubricant directly to the tire pressure warning valve and transmitter.

(d) Install the upper bead.

NOTICE: Make sure that the tire bead and tool do not interfere with the main body of the tire pressure warning valve and transmitter and that it is not clamped by the bead.

(e) After the tire is inflated, the valve nut may be loose.

Retighten the nut to the specified torque and then check for air leaks with soapy water.

Torque: 4.0 N*m (41 kgf*cm, 35 in.*lbf)

NOTICE: No further tightening is required once the nut is tightened to the specified torque.

2. INSTALL FRONT WHEEL Torque: 103 N*m (1050 kgf*cm, 76 ft.*lbf)

3. INSTALL REAR WHEEL Torque: 103 N*m (1050 kgf*cm, 76 ft.*lbf)

4. INSPECT TIRES

HINT: See page TW-2.

5. REGISTER TRANSMITTER ID

HINT: See page TW-20.

6. INSPECT TIRE PRESSURE WARNING SYSTEM

HINT: See page TW-25.

Removal

Removal

1. REMOVE FRONT WHEEL

2. REMOVE REAR WHEEL

3. REMOVE TIRE PRESSURE WARNING VALVE AND TRANSMITTER

(a) Remove the valve core and cap, and release the air

from the tire.

(b) After ensuring tha ...

Disposal

Disposal

HINT:

The tire pressure warning valve and transmitter is powered

by a lithium battery. When disposing of the tire pressure

warning valve and transmitter, remove the battery and

dispose of it corre ...

Other materials:

DVD Player Mechanical Error/ DVD Insertion and Ejection Error/ DVD Reading

Abnormal

DTC 44-10 DVD Player Mechanical Error

DTC 44-11 DVD Insertion and Ejection Error

DTC 44-12 DVD Reading Abnormal

DESCRIPTION

TC No.

DTC Detection Condition

Trouble Area

44-10

A mechanical error in the DVD player is detected while

the DVD is not being insert ...

Fail-safe chart

If any of the following DTCs are set, the ECM enters fail-safe

mode to allow the vehicle to be driven temporarily.

HINT:

*1: The vehicle can be driven slowly when the accelerator

pedal is depressed firmly and slowly. If the accelerator

pedal is depressed quickly, the vehicle may ...

Air Mix Damper Control Servo Motor Circuit (Driver Side)

DESCRIPTION

The air mix control servo motor (air mix damper servo sub-assembly) is

controlled by the A/C amplifier.

The air mix control servo motor moves the air mix damper by rotating (normal,

reverse) with electrical

power from the A/C amplifier.

This adjusts the mix ratio of the air t ...