Toyota Sienna Service Manual: Hydraulic test

1. Perform hydraulic test

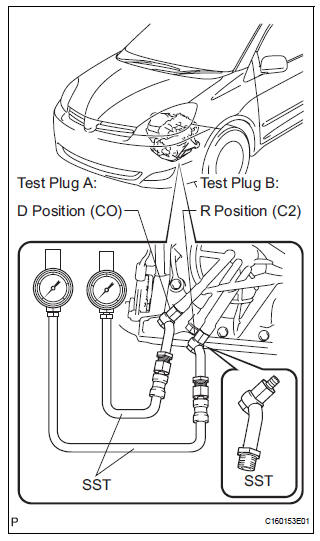

(a) Measure the line pressure.

NOTICE:

|

(1) Warm up the ATF (Automatic Transmission Fluid).

(2) Lift the vehicle up.

(3) Remove the engine under cover.

(4) Connect the intelligent tester together with the CAN VIM (controller area network vehicle interface module) to the DLC3.

(5) Remove the test plug A on the transaxle case front left side and install the SST.

SST 09992-00095 (09992-00231, 09992- 00271)

| NOTICE: There is a difference in installation point between D position and R position. |

(6) Start the engine.

(7) Using intelligent tester, shift to D position and hold 3rd gear by active test, and measure the line pressure in idling.

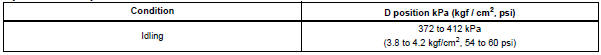

Specified line pressure:

(8) Turn the ignition switch off.

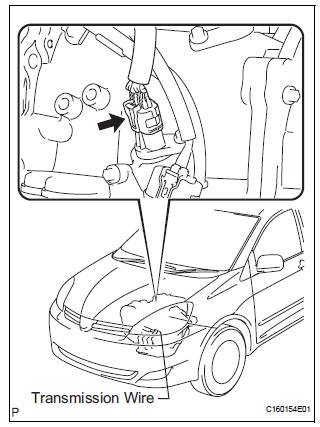

(9) Disconnect the connector of the transmission wire.

HINT: Disconnect the connector only when performing the D position stall test.

(10)Start the engine.

(11)Firmly depress the brake pedal, shift to the D position, depress the accelerator pedal all the way down and check the line pressure while the stall test is performed.

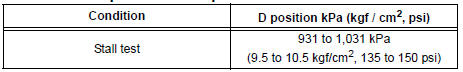

Specified line pressure:

(12)Turn the ignition switch off.

(13)Remove the SST, install the test plug A.

(14)Remove the test plug B, install the SST and start engine.

SST 09992-00095 (09992-00231, 09992- 00271)

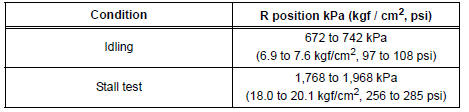

(15)Connect the transmission wire connector, depress the brake pedal firmly, shift to the R position and check that the line pressure while the engine is idling and during the stall test.

Specified line pressure:

(16)Remove the SST, install the test plug B.

(17)Clear the DTC.

Evaluation:

| Problem | Possible cause |

| Measured values are higher than specified in all positions |

|

| Measured values are lower than specified in all positions |

|

| Pressure is low in the D position only |

|

| Pressure is low in the R position only |

|

Mechanical system tests

Mechanical system tests

1. PERFORM MECHANICAL SYSTEM TESTS

(a) Measure the stall speed.

The object of this test is to check the overall

performance of the transaxle and engine by

measuring the stall speeds in the D pos ...

Manual shifting test

Manual shifting test

1. Perform manual shifting test

Hint:

With this test, it can be determined whether the

trouble occurs in the electrical circuit or is a

mechanical problem in the transaxle.

If any abnormali ...

Other materials:

Reassembly

1. INSTALL OIL PUMP COVER

(a) Coat the drive and driven rotors with engine oil and

place them into the timing chain cover with the

marks facing outward (oil pump cover side). Check

that the rotors rotate smoothly.

(b) Install the oil pump cover with the 8 bolts.

Torque: 9.1 N*m (93 kgf ...

Installation

1. INSTALL REAR AXLE HUB & BEARING ASSEMBLY LH

(a) Install the hub & Bearing assembly LH with the 4

bolts.

Torque: 56 N*m (571 kgf*cm, 41 ft.*lbf)

2. INSPECT BEARING BACKLASH (See page AH-16)

3. INSPECT AXLE HUB DEVIATION (See page AH-16)

4. CONNECT SKID CONTROL SENSOR WIRE

(a) Co ...

Reassembly

1. INSTALL MAGNETIC CLUTCH ASSEMBLY

(a) Install the magnetic clutch stator while aligning the

protrusion on the stator with the notch on the air

compressor assembly as shown in the illustration.

(b) Using a snap ring expander, install a new snap ring

with the chamfered side facing up.

...