Toyota Sienna Service Manual: Installation

1. INSTALL BRAKE ACTUATOR

(a) Install the brake actuator assembly with the 2 nuts.

Torque: 5.4 N*m (55 kgf*cm, 48 in.*lbf)

2. INSTALL BRAKE ACTUATOR WITH BRACKET

(a) Install the actuator with bracket with the 3 bolts.

Torque: 20 N*m (199 kgf*cm, 14 ft.*lbf)

NOTICE: Be careful not to damage the brake tubes and wire harness.

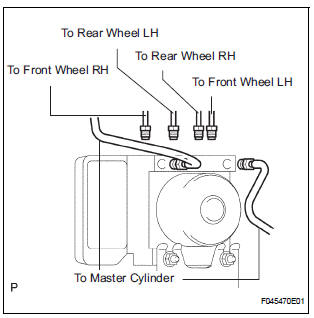

(b) Using SST, connect each brake tube to correct positions of the actuator with bracket, as shown in the illustration.

Torque: 15 N*m (155 kgf*cm, 11 ft.*lbf)

(c) Connect the brake actuator connector assembly.

3. INSTALL AIR CLEANER ASSEMBLY WITH HOSE

4. FILL RESERVOIR WITH BRAKE FLUID (See page BR- 3)

5. BLEED BRAKE MASTER CYLINDER SUBASSEMBLY (See page BR-3)

6. BLEED BRAKE LINE (See page BR-4)

7. CHECK BRAKE FLUID LEAKAGE

8. CHECK FLUID LEVEL IN RESERVOIR (See page BR- 7)

9. CONNECT BATTERY NEGATIVE TERMINAL

10. PERFORM INITIALIZATION

11. CHECK BRAKE ACTUATOR WITH INTELLIGENT TESTER

HINT: See page BC-183.

Removal

Removal

1. DRAIN BRAKE FLUID

NOTICE:

Wash brake fluid off immediately if it adheres to any

painted surface.

2. DISCONNECT BATTERY NEGATIVE TERMINAL

3. REMOVE AIR CLEANER ASSEMBLY WITH HOSE

4. REMOVE BRA ...

Front speed sensor

Front speed sensor

Components

...

Other materials:

Precaution

1. TIRE PRESSURE WARNING SYSTEM PRECAUTION

(a) When the tire pressure warning light comes on,

immediately check the tire pressure of the tire and

adjust it to the specified value. (The tire pressure

warning light will come on after blinking for 1 minute

if there is an open in the tire press ...

What to do if... (Troubleshooting)

If there is a problem with the hands-free system or a Bluetooth®

device, first check the table below.

When using the hands-free system with a Bluetooth® device

The hands-free system or Bluetooth® device does not

work.

The connected device may not be a compatible Bl ...

Adjustment

1. VEHICLE PREPARATION FOR HEADLIGHT AIMING

ADJUSTMENT

Prepare the vehicle:

Ensure there is no damage or deformation to the

body around the headlights.

Fill the fuel tank.

Make sure that the oil is filled to the specified

level.

Make sure that the c ...