Toyota Sienna Service Manual: Installation

1. INSTALL SEAT POSITION AIRBAG SENSOR

- Check that the ignition switch is off.

- Check that the negative battery (-) terminal is disconnected.

CAUTION: After disconnecting the negative battery terminal, wait for at least 90 seconds before starting the operation.

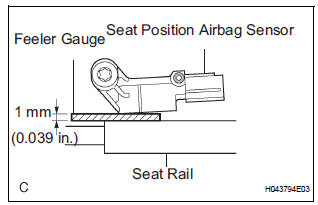

- Using a feeler gauge 1 mm (0.039 in.), install the seat position sensor.

NOTICE:

- If the seat position sensor has been dropped, or there are any cracks, dents or other defects in the case or connector, replace it with a new one.

- When installing the seat position sensor, be careful that the SRS wiring does not interfere with other parts and that it is not pinched between other parts.

HINT: Be sure that a clearance between the seat position sensor and the seat rail is within 0.6 mm (0.023 in.) to 1.4 mm (0.055 in.).

- Using a "torx" socket wrench (T30), tighten the

"torx" screw to install the seat position sensor.

Torque: 8.0 N*m (82 kgf*cm, 71 in.*lbf)

- Make sure that a clearance between the seat position sensor and the seat rail is within 0.6 mm (0.023 in.) to 1.4 mm (0.055 in.).

- Check that there is no looseness in the installation parts of the seat position sensor.

- Connect the connector to the seat position sensor.

2. INSTALL SEAT SLIDE POSITION SENSOR PROTECTOR

3. INSTALL FRONT SEAT CUSHION SHIELD ASSEMBLY (for Power Seat)

4. INSTALL SLIDE AND VERTICAL POWER SEAT SWITCH KNOB (for Power Seat)

5. INSTALL RECLINING POWER SEAT SWITCH KNOB (for Power Seat)

6. INSTALL FRONT SEAT CUSHION SHIELD LH (for Manual Seat)

7. INSTALL VERTICAL ADJUSTING HANDLE NO.2 (for Manual Seat)

8. INSTALL VERTICAL SEAT ADJUSTER KNOB CAP (for Manual Seat)

9. INSTALL RECLINING ADJUSTER RELEASE HANDLE LH (for Manual Seat)

10. INSTALL FRONT SEAT ASSEMBLY (for Manual Seat)

11. INSTALL FRONT SEAT ASSEMBLY (for Power Seat)

12. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

13. PERFORM INITIALIZATION

- Perform initialization.

HINT: Some systems need initialization when disconnecting the cable from the negative battery terminal.

14. INSPECT SLIDE ADJUSTER LOCK (for Manual Seat)

15. INSPECT POWER SEAT OPERATION (for Power Seat)

16. INSPECT SEAT HEATER OPERATION (w/ Seat Heater System)

17. INSPECT SRS WARNING LIGHT

- Inspect the SRS warning light

Removal

Removal

1. PRECAUTION

CAUTION: Be sure to read "PRECAUTION" thoroughly before

servicing.

2. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

CAUTION:

Wait for 90 seconds after disconnecting th ...

Occupant classification ECU

Occupant classification ECU

COMPONENTS

...

Other materials:

Definition of terms

Terms

Definitions

Monitor Description

Description of what ECM monitors and how to detect malfunctions

(monitoring purpose and details).

Related DTCs

A group of diagnostic trouble codes that are output by ECM based on

the same malfunction detection lo ...

Stop Light Switch Circuit Malfunction

DTC P0571 Stop Light Switch Circuit Malfunction

DESCRIPTION

The ECM receives the brake demand signal from the distance control ECU and

transmits it to the skid

control ECU (brake actuator assembly).

The skid control ECU (brake actuator assembly) receives a signal from the ECM

and operates ...

Removal and installation of engine intake parts

REMOVAL AND INSTALLATION OF ENGINE INTAKE PARTS

(a) If any metal particles enter inlet system parts, this

may damage the engine.

(b) When removing and installing inlet system parts,

cover the openings of the removed parts and engine

openings. Use gummed tape or other suitable

materials ...