Toyota Sienna Service Manual: Installation

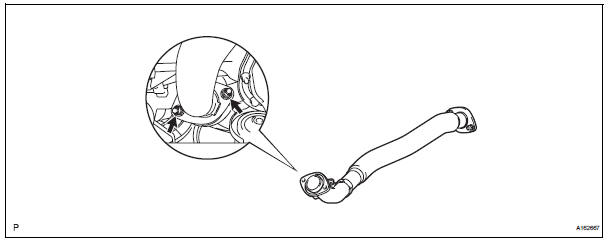

1. INSTALL HEATED OXYGEN SENSOR (for Bank 2 Sensor 2) (See page EC-39) 2. INSTALL FRONT EXHAUST PIPE ASSEMBLY

(a) Install a new gasket to the front exhaust pipe assembly.

(b) Install the front exhaust pipe assembly with the 2 nuts.

Torque: 62 N*m (632 kgf*cm, 46 ft.*lbf)

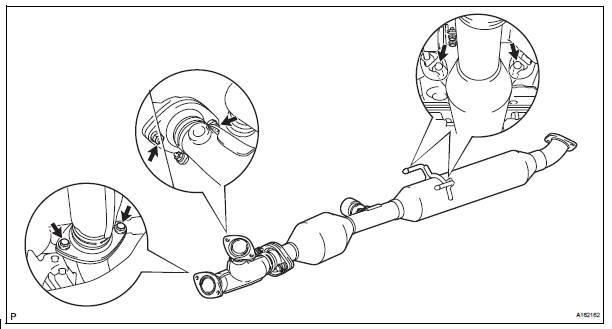

3. V

V(A) install 2 new gaskets to the center exhaust pipe assembly.

(B) connect the 2 exhaust pipe supports, and install the center exhaust pipe assembly.

(C) install 2 new bolts and 2 nuts.

Torque: bolt 43 n*m (438 kgf*cm, 32 ft.*Lbf) nut 62 n*m (632 kgf*cm, 46 ft.*Lbf)

4. Install no. 1 Exhaust pipe support bracket

(a) Install the No. 1 exhaust pipe support bracket to oil pan sub-assembly with 2 new nuts.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf) (b) Loosen the No. 1 exhaust pipe support bracket bolts.

(c) Install the clamp to No. 1 exhaust pipe support bracket.

(d) Retighten the No. 1 exhaust pipe support bracket bolts.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf) (e) Install the clamp with a new bolt.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

(f) Connect the heated oxygen sensor (for bank 2 sensor 2) connector.

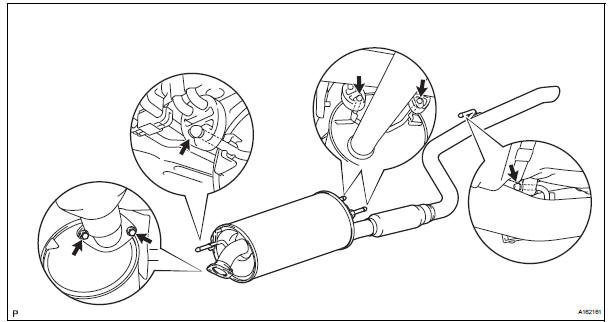

5. INSTALL TAIL EXHAUST PIPE ASSEMBLY

(a) Install a new gasket to the center exhaust pipe assembly.

(b) Connect the 4 exhaust pipe supports, and install the tail exhaust pipe assembly.

(c) Install 2 new bolts.

Torque: 43 N*m (438 kgf*cm, 32 ft.*lbf)

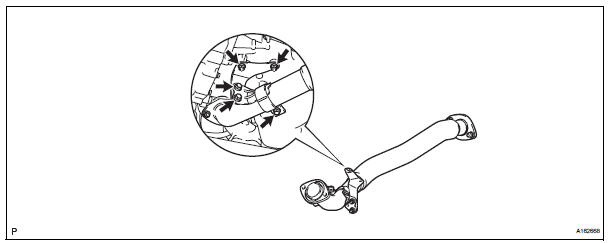

6. INSTALL HEATED OXYGEN SENSOR (for Bank 1 Sensor 2) (See page EC-41)

7. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

8. INSPECT FOR EXHAUST GAS LEAK

If exhaust gas is leaking, repair the leak. Replace damaged parts as necessary.

Removal

Removal

1. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

2. REMOVE HEATED OXYGEN SENSOR (for Bank 1

Sensor 2) (See page EC-38)

3. REMOVE TAIL EXHAUST PIPE ASSEMBLY

(a) Remove the 2 bolts.

(b) Discon ...

2Gr-fe cooling

2Gr-fe cooling

...

Other materials:

Cup holders

Front

Press in and release the front cup

holder.

Console box type A

(if equipped)

Console box type B

(if equipped)

Pull the lid down.

Console box type C

(if equipped)

Second seat (if equipped)

Removing the second center seat.

Rear

...

Only Back Door cannot be Opened

DESCRIPTION

With power back door: The signal for manual locking/unlocking operation of

the driver/passenger side

door and the signal for locking/unlocking operation interlocked with the driver

side door key cylinder are

sent to the back door ECU from the body ECU using the MPX line. In respon ...

Removal

1. REMOVE REAR WHEEL

2. REMOVE SKID CONTROL SENSOR WIRE (for 2WD)

(a) Disconnect the skid control sensor connector.

(b) Remove the bolt and disconnect the bracket from

the rear axle beam assembly.

HINT:

Separate the RH side by the same procedures as

the LH side.

3. SEPARATE SPEED SENSO ...