Toyota Sienna Service Manual: Removal

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

2. REMOVE HEATED OXYGEN SENSOR (for Bank 1 Sensor 2) (See page EC-38)

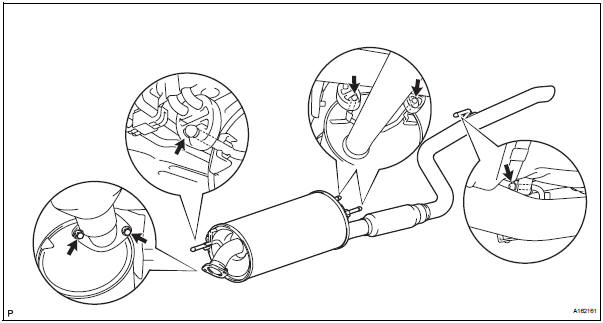

3. REMOVE TAIL EXHAUST PIPE ASSEMBLY

(a) Remove the 2 bolts.

(b) Disconnect the 4 exhaust pipe supports and remove the tail exhaust pipe assembly.

(c) Remove the gasket from the center exhaust pipe assembly.

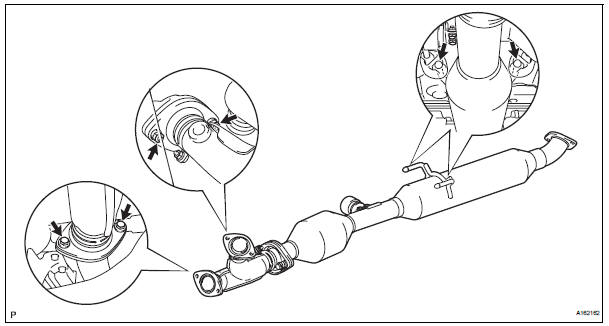

4. REMOVE CENTER EXHAUST PIPE ASSEMBLY

(a) Remove the 2 bolts and 2 nuts.

(b) Disconnect the 2 exhaust pipe supports and remove the center exhaust pipe assembly.

(c) Remove the gaskets from the center exhaust pipe assembly and the front exhaust pipe assembly.

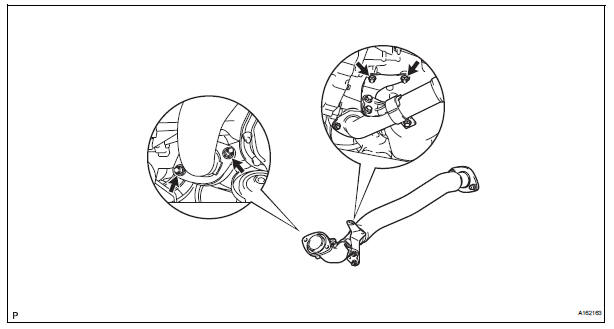

5. REMOVE FRONT EXHAUST PIPE ASSEMBLY

(a) Disconnect the heated oxygen sensor (for bank 2 sensor 2) connector.

(b) Remove the 4 nuts and front exhaust pipe assembly.

(c) Remove the gasket from the front exhaust pipe assembly.

6. REMOVE NO. 1 EXHAUST PIPE SUPPORT BRACKET

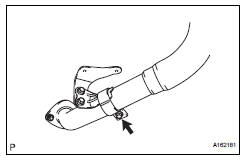

(a) Remove the bolt and No. 1 exhaust pipe support bracket.

7. REMOVE HEATED OXYGEN SENSOR (for Bank 2 Sensor 2) (See page EC-38)

Exhaust pipe (for 4wd)

Exhaust pipe (for 4wd)

Components

...

Installation

Installation

1. INSTALL HEATED OXYGEN SENSOR (for Bank 2

Sensor 2) (See page EC-39)

2. INSTALL FRONT EXHAUST PIPE ASSEMBLY

(a) Install a new gasket to the front exhaust pipe

assembly.

(b) Install the front ...

Other materials:

Reassembly

1. INSTALL FUEL PRESSURE REGULATOR ASSEMBLY

(a) Apply a light coat of gasoline or spindle oil to the 2

new O-rings, and install it to the fuel pressure

regulator.

(b) Apply a light coat of gasoline or spindle oil to the 2

O-rings again, and install the fuel pressure regulator

to the No. ...

Ignition Switch Circuit

DESCRIPTION

When the ignition switch is turned to the ON position, battery positive

voltage is applied to terminal IG of

the ECU. When battery positive voltage is applied to terminal IG of the ECU

while the theft deterrent

system is operating, the warning stops.

WIRING DIAGRAM

INSPECTIO ...

Back door lock

INSPECTION

1. INSPECT BACK DOOR LOCK ASSEMBLY (W/O

CLOSER)

Check operation of the door lock.

Using a screwdriver, push the latch in order to

put the back door lock in the locked condition

(full-latch position).

Connect the battery positive (+) lead to terminal ...