Toyota Sienna Service Manual: Installation

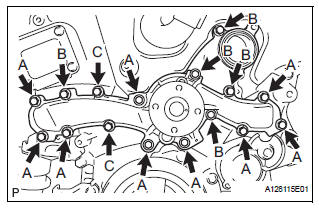

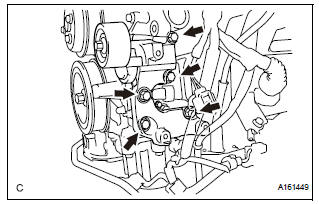

1. INSTALL WATER PUMP ASSEMBLY

(a) Install a new water pump gasket and the water pump assembly with the 16 bolts.

Torque: Bolt A 21 N*m (214 kgf*cm, 15 ft.*lbf) Bolts B and C 9.1 N*m (93 kgf*cm, 81 in.*lbf)

NOTICE:

|

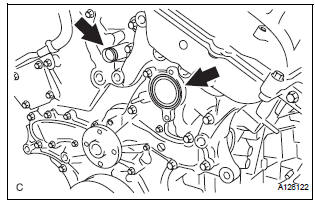

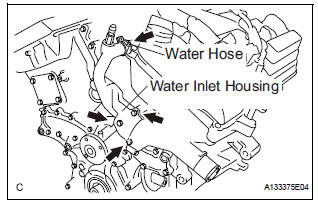

2. INSTALL WATER INLET HOUSING

(a) Install a new water inlet housing No. 1 gasket and water outlet pipe O-ring.

(b) Install the water inlet housing with the 2 bolts and nut.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

| NOTICE: Be careful not to allow the O-ring to get caught between the parts. |

(c) Connect the water hose.

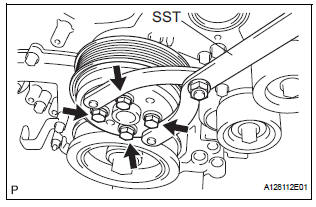

3. INSTALL WATER PUMP PULLEY

(a) Temporarily install the water pump pulley with the 4 bolts.

(b) Using SST, hold the water pump pulley.

SST 09960-10010 (09962-01000, 09963-00700) (c) Tighten the 4 bolts.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

4. INSTALL V-RIBBED BELT TENSIONER ASSEMBLY

(a) Install the V-ribbed belt tensioner assembly with the 5 bolts.

Torque: 43 N*m (438 kgf*cm, 32 ft.*lbf)

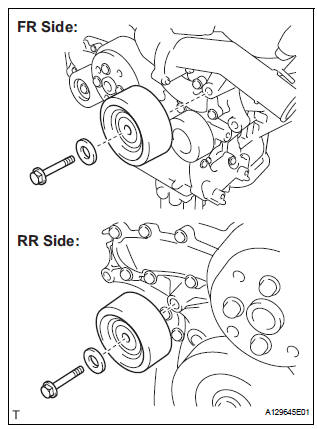

5. INSTALL NO. 2 IDLER PULLEY SUB-ASSEMBLY

(a) Install the 2 idler pulley cover plates and idler pulley sub-assemblies with the 2 bolts.

Torque: 43 N*m (438 kgf*cm, 32 ft.*lbf)

6. INSTALL NO. 1 ENGINE FRONT MOUNTING BRACKET LH (See page EM-45) 7. INSTALL GENERATOR ASSEMBLY (See page CH-26) 8. INSTALL COMPRESSOR AND MAGNETIC CLUTCH (See page AC-231) 9. INSTALL ENGINE HANGERS (See page EM-50) 10. REMOVE ENGINE STAND 11. INSTALL ENGINE ASSEMBLY WITH TRANSAXLE HINT: See page EM-44 12. ADD ENGINE COOLANT (See page CO-7) 13. INSPECT FOR COOLANT LEAK (See page CO-1)

Inspection

Inspection

1. Inspect water pump assembly

(a) Visually check the drain hole and air hole for coolant

leakage.

(b) Turn the pulley, and check that the water pump

bearing moves smoothly and noiselessly.

...

Thermostat

Thermostat

Components

...

Other materials:

Air Outlet Damper Position Sensor Circuit

DESCRIPTION

This sensor detects the position of the air outlet control servo motor and

sends the appropriate signals to

the A/C amplifier. The position sensor is built in the air outlet control servo

motor. The position sensor's

resistance changes as the air outlet control servo motor arm ...

Removal

1. PRECAUTION

HINT:

See page RS-1

2. DISCONNECT BATTERY NEGATIVE TERMINAL

Wait for 90 seconds after disconnecting the battery

terminal to prevent the airbag working.

3. PLACE FRONT WHEELS FACING STRAIGHT AHEAD

4. REMOVE STEERING WHEEL COVER LOWER NO.2

(See page RS-424)

5. REMOVE STEERING WH ...

Lumbar support adjuster assembly

INSPECTION

1. INSPECT LUMBAR SUPPORT ADJUSTER ASSEMBLY

Check operation of the lumbar support adjuster

motor.

Check if the lumbar support adjuster moves

smoothly when the battery is connected to the

lumbar support adjuster motor connector

terminal.

OK

If the r ...