Toyota Sienna Service Manual: On-vehicle inspection

1. CHECK RADIATOR RESERVOIR CAP SUBASSEMBLY

a) Measure the valve opening pressure.

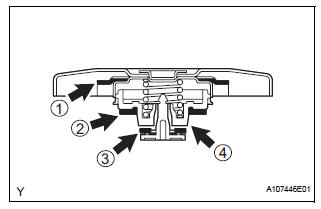

(1) If there are water stains or foreign matter on rubber packings 1, 2 or 3, clean the part(s) with water and finger scouring.

(2) Check that rubber packings 1, 2 and 3 are not deformed, cracked or swollen.

(3) Check that rubber packings 3 and 4 are not stuck together.

(4) Apply engine coolant to rubber packings 2 and 3 before using the radiator cap tester.

(5) When using the cap tester, tilt it to 30° or more above the horizontal.

(6) Pump the cap tester several times, and check the maximum pressure*.

Pump speed: 1 pump per second

*: Even if the cap cannot maintain the maximum pressure, it is not a defect.

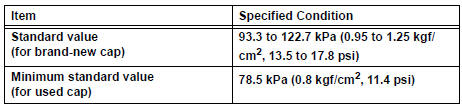

Judgment criterion

If the maximum pressure is less than the minimum standard value, replace the radiator reservoir cap sub-assembly.

Radiator

Radiator

COMPONENTS

...

On-vehicle cleaning

On-vehicle cleaning

1. INSPECT RADIATOR ASSEMBLY

(a) Check that the radiator and condenser are not

blocked with leaves, dirt, or insects. Clean the hose

connections.

If the fins are blocked, wash them with water or ...

Other materials:

Pressing Power Switch does not Turn on System

INSPECTION PROCEDURE

1 CHECK CABIN

Check that conditions in the cabin are not likely to cause

condensation.

HINT:

This problem occurs when the cabin is humid and the

temperature rapidly changes. This condition may

produce condensation, resulting in a short circuit.

OK:

Condensation ...

Canceling the power back door system (vehicles with power

back door)

Turn the main switch off to disable

the power back door system.

Off

On*

*: The orange line at the top of the

switch indicates that the power

back door system is on.

Luggage compartment light

The luggage compartment light turns on

when the back door is opened with the

luggage ...

Seat belt warning system

PARTS LOCATION

Problem symptoms table

SEAT BELT WARNING SYSTEM

Symptom

Suspected Area

Driver side seat belt waning light does not operate

Fuse

Combination meter

Center airbag sensor assembly

Front seat inner belt assembly

Wire harness

...