Toyota Sienna Service Manual: Open in Side Squib LH Circuit

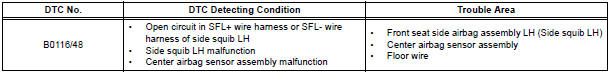

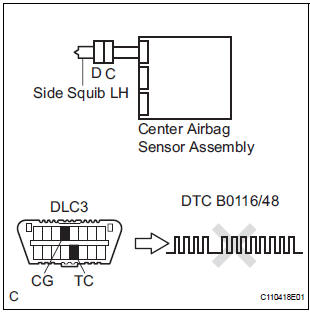

DTC B0116/48 Open in Side Squib LH Circuit

DESCRIPTION

The side squib LH circuit consists of the center airbag sensor assembly and the front seat side assembly LH.

This circuit instructs the SRS to deploy when deployment conditions are met.

DTC B0116/48 is recorded when an open circuit is detected in the side squib LH circuit.

WIRING DIAGRAM

INSPECTION PROCEDURE

HINT:

- Perform the simulation method by selecting the "check mode" (signal check) with the intelligent tester.

- After selecting the "check mode" (signal check), perform the simulation method by wiggling each connector of the airbag system or driving the vehicle on a city or rough road

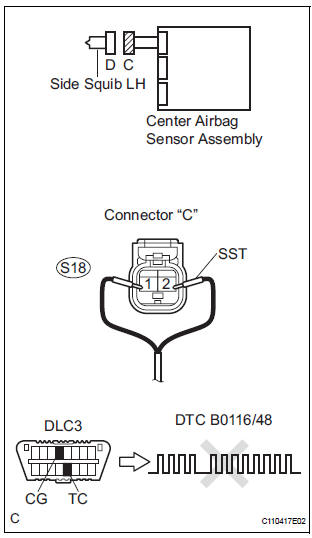

1 CHECK FRONT SEAT SIDE AIRBAG ASSEMBLY LH (SIDE SQUIB LH)

- Turn the ignition switch to the LOCK position.

- Disconnect the negative (-) terminal cable from the battery, and wait for at least 90 seconds.

- Disconnect the connectors from the front seat side airbag assembly LH.

- Connect the black wire side of SST (resistance 2.1 Ω) to the floor wire.

CAUTION: Never connect a tester to the front seat side airbag assembly LH (side squib LH) for measurement, as this may lead to a serious injury due to airbag deployment.

NOTICE: Do not forcibly insert the SST into the terminals of the connector when connecting.

Insert the SST straight into the terminals of the connector.

SST 09843-18060

- Connect the negative (-) terminal cable to the battery, and wait for at least 2 seconds.

- Turn the ignition switch to the ON position, and wait for at least 60 seconds.

- Clear the DTCs stored in memory.

- Turn the ignition switch to the LOCK position.

- Turn the ignition switch to the ON position, and wait for at least 60 seconds.

- Check the DTCs

OK: DTC B0116/48 is not output.

HINT: Codes other than DTC B0116/48 may be output at this time, but they are not related to this check.

REPLACE FRONT SEAT ASSEMBLY LH

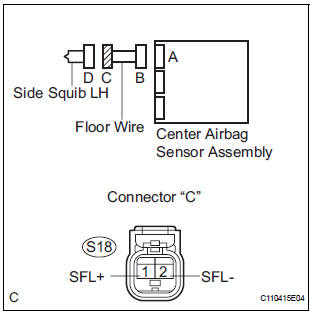

2 CHECK FLOOR WIRE (SIDE SQUIB LH CIRCUIT)

- Turn the ignition switch to the LOCK position.

- Disconnect the negative (-) terminal cable from the battery, and wait for at least 90 seconds.

- Disconnect the SST (resistance 2.1 Ω) from the floor wire.

- Disconnect the connector from the center airbag sensor assembly.

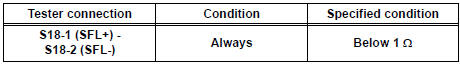

- Measure the resistance according to the value(s) in the table below.

Standard resistance

3 CHECK CENTER AIRBAG SENSOR ASSEMBLY

- Connect the connectors to the front seat side airbag assembly LH and the center airbag sensor assembly.

- Connect the negative (-) terminal cable to the battery, and wait for at least 2 seconds.

- Turn the ignition switch to the ON position, and wait for at least 60 seconds.

- Clear the DTCs stored in memory.

- Turn the ignition switch to the LOCK position.

- Turn the ignition switch to the ON position, and wait for at least 60 seconds.

- Check the DTCs.

OK: DTC B0116/48 is not output.

HINT: Codes other than code B0116/48 may be output at this time, but they are not related to this check.

USE SIMULATION METHOD TO CHECK

Short in Side Squib LH Circuit

Short in Side Squib LH Circuit

DTC B0115/47 Short in Side Squib LH Circuit

DESCRIPTION

The side squib LH circuit consists of the center airbag sensor assembly and

the front seat side airbag

assembly LH.

This circuit instruc ...

Short to GND in Side Squib LH Circuit

Short to GND in Side Squib LH Circuit

DTC B0117/45 Short to GND in Side Squib LH Circuit

DESCRIPTION

The side squib LH circuit consists of the center airbag sensor assembly and

the front seat side airbag

assembly LH.

This circuit ...

Other materials:

System description

1. POWER MIRROR CONTROL SYSTEM DESCRIPTION

This system has these functions: automatic glare-resistant

electrochromic (EC) mirror, electrical remote control type

mirror, memory function, foot light function, and rear

window defogger-linked mirror defogger.

2. FUNCTION OF MAIN COMPONENT

...

Differential system

PRECAUTION

NOTICE:

When disconnecting the negative (-) battery terminal,

initialize the following systems after the terminal is

reconnected.

1. Before disassembly, clean the outside of the rear

differential assembly and remove any sand or mud to

prevent it from entering the inside of the as ...

Air outlet control servo motor (for rear air conditioning system)

ON-VEHICLE INSPECTION

1. INSPECT REAR AIR OUTLET CONTROL SERVO

MOTOR

(a) Inspect servo motor operation.

(1) Connect the positive (+) lead from the battery

to terminal 4 and negative (-) lead to terminal 5,

then check that the arm turns to "FOOT" side

smoothly.

(2) Connect t ...