Toyota Sienna Service Manual: Reassembly

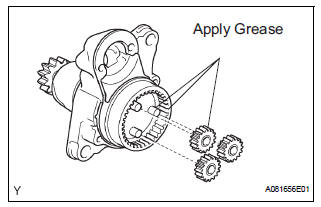

1. INSTALL PLANETARY GEAR

(a) Apply grease to the planetary gears and pin parts of the planetary shaft.

(b) Install the 3 planetary gears.

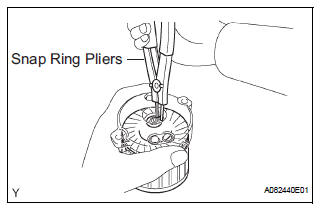

2. INSTALL STARTER ARMATURE ASSEMBLY

(a) Apply grease to the plate washer and the armature shaft.

(b) Install the starter armature to the starter commutator end frame.

(c) Using snap ring pliers, install the plate washer and a new snap ring.

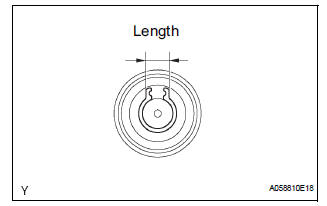

(d) Using a vernier caliper, measure length of the snap ring.

Maximum length: 5.0 mm (0.197 in.) If the length is greater than the maximum, replace it with a new snap ring

3. INSTALL DRIVE HOUSING STARTER BEARING COVER

(a) Install the drive housing starter bearing cover to the starter commutator end frame.

4. INSTALL STARTER ARMATURE PLATE

(a) Insert the starter armature plate to the starter yoke.

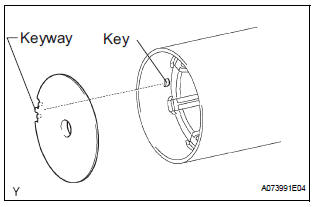

(b) Align the keyway of the starter plate with the key inside the starter yoke, and install the starter plate.

5. INSTALL STARTER COMMUTATOR END FRAME ASSEMBLY

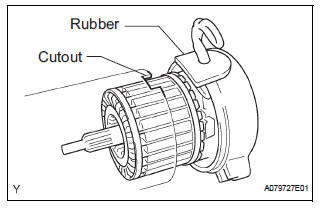

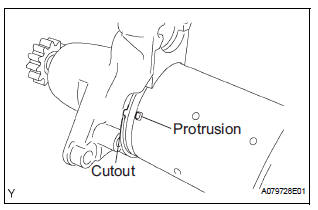

(a) Align the rubber with the convex cutout of starter yoke.

(b) Install starter commutator end frame to the starter yoke.

6. INSTALL STARTER YOKE ASSEMBLY

(a) Align the key of the starter yoke with the keyway of repair service starter kit.

(b) Install the starter yoke with the 2 through bolts.

Torque: 6.0 N*m (61 kgf*cm, 53 in.*lbf)

7. INSTALL REPAIR SERVICE STARTER KIT

(a) Apply grease to the plunger and the hook.

(b) Hang the plunger hook of the repair service starter kit to the drive lever.

(c) Install the plunger and return spring.

(d) Install the repair service starter kit with the 2 screws.

Torque: 7.5 N*m (76 kgf*cm, 66 in.*lbf)

(e) Connect the lead wire to the repair service starter kit with the nut.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

Inspection

Inspection

1. Inspect starter assembly

NOTICE:

These tests must be performed within 3 to 5 seconds

to avoid burning out the coil.

(a) Perform the pull-in test.

(1) Disconnect the lead ...

Installation

Installation

1. INSTALL STARTER ASSEMBLY

(a) Install the starter with the 2 bolts.

Torque: 37 N*m (380 kgf*cm, 26 ft.*lbf) for bolt

(b) Connect the starter connector.

(c) Install the terminal nut a ...

Other materials:

How to proceed with troubleshooting

The intelligent tester can be used at steps 3, 7, 10, and 13.

1 VEHICLE BROUGHT TO WORKSHOP

2 CUSTOMER PROBLEM ANALYSIS

(a) Interview the customer to confirm the trouble.

3 DTC CHECK/CLEAR AND FREEZE FRAME DATA

4 PROBLEM SYMPTOM CONFIRMATION

5 PROBLEM SYMPTOM SIMULATION

6 SYMPTOM SI ...

Back Sonar Sensor LH Circuit

DESCRIPTION

An ultrasonic sensor consists of a sensor portion that transmits and receives

ultrasonic waves and a preamplifier

that amplifies them. The ultrasonic sensor outputs the ultrasonic waves and

sends the received

signals to the clearance warning ECU.

WIRING DIAGRAM

INSPECTION PR ...

System description

1. GENERAL

In conjunction with impact absorbing structure for a

frontal collision, the SRS (Supplemental Restraint

System) driver airbag and front passenger airbag

were designed to supplement seat belts in the event

of a frontal collision in order to help reduce shock to

the head and c ...