Toyota Sienna Service Manual: Reassembly

1. INSTALL INPUT SHAFT OIL SEAL RING

(a) Compress a new input shaft oil seal ring from both sides to reduce dimension A.

Dimension A: 5 mm (0.197 in.)

(b) Coat the oil seal ring with ATF and install it to the input shaft.

NOTICE: Do not expand the end gap of the oil seal ring too much. Fix the hooks firmly.

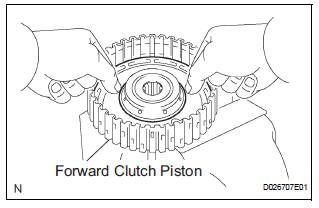

2. INSTALL FORWARD CLUTCH PISTON SUBASSEMBLY

(a) Coat the forward clutch piston with ATF, and install it to the input shaft.

NOTICE: Be careful not to damage the lip of the forward clutch piston.

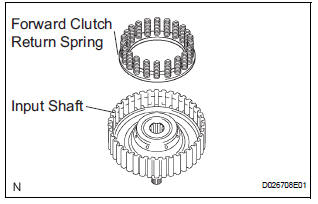

3. INSTALL FORWARD CLUTCH RETURN SPRING SUB-ASSEMBLY

(a) Install the return spring to the input shaft.

NOTICE: Installing the spring sub-assembly, check that all of the springs are fit in the piston correctly.

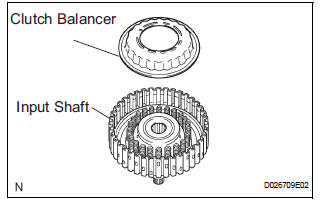

(b) Coat the clutch balancer with ATF.

(c) Install the clutch balancer to the input shaft.

NOTICE:

- Be careful not to damage the lip of the forward clutch balancer.

- Make sure that the clutch balancer is not pinched and that there are no other defects at the lip.

- Apply sufficient ATF to the sealing lip before installation.

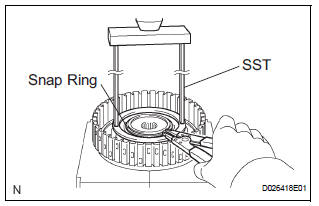

(d) Place SST on the clutch balancer, and compress the clutch balancer with a press.

SST 09387-00020

(e) Install the snap ring with a snap ring expander.

(f) Be sure that the end gap of the snap ring is not aligned with the spring retainer claw.

NOTICE:

- Stop the press when the spring seat is lowered to the place 1 to 2 mm (0.039 to 0.078 in.) from the snap ring groove.

- This prevents the spring seat from being deformed.

- Do not expand the snap ring excessively.

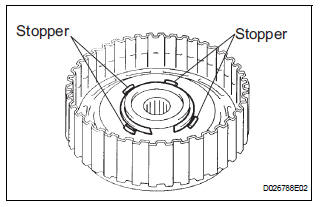

(g) Set the end gap of the snap ring in the piston as shown in the illustration.

NOTICE: The end gap of the snap ring should not align with any of the stoppers.

4. INSTALL FORWARD MULTIPLE DISC CLUTCH DISC

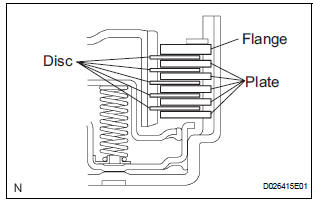

(a) Coat the 5 discs with ATF.

(b) Install the 5 plates, 5 discs and flange input shaft.

NOTICE: Make sure that the plates, discs, and flange are installed as shown in the illustration.

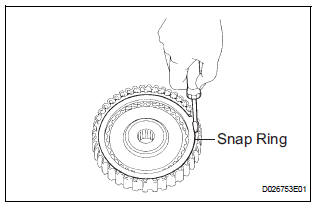

(c) Using a screwdriver, install the snap ring.

(d) Check that the end gap of the snap ring is not aligned with one of the cutouts.

NOTICE: The snap ring should be fully engaged in the groove of the drum.

5. INSPECT PACK CLEARANCE OF FORWARD CLUTCH

HINT: (See page AX-243)

6. INSPECT FORWARD MULTIPLE DISC CLUTCH DISC

HINT: (See page AX-243)

Inspection

Inspection

1. INSPECT PACK CLEARANCE OF FORWARD CLUTCH

(a) Install the forward clutch on the oil pump.

NOTICE:

Be careful not to damage the oil seal ring of oil

pump.

b) Using a dial indicator, measure ...

Direct clutch

Direct clutch

Components

...

Other materials:

Fuel Pump Primary Circuit

DTC P0230 Fuel Pump Primary Circuit

DESCRIPTION

This DTC is designed to detect a malfunction in the fuel pump

(FUEL PUMP) relay circuit. When the

system is normal, the battery voltage is applied to FPR terminal of the ECM

while the FUEL PUMP

relay is turned OFF. If the battery v ...

Under hood

GENERAL MAINTENANCE

1. GENERAL NOTES

Maintenance requirements very depending on the

country.

Check the maintenance schedule in the owner's

manual supplement.

Following the maintenance schedule is mandatory.

Determine the appropriate time to service the vehicle

using either miles dri ...

Transmitter ID not Registered

DTC C2171/71 Transmitter ID not Registered

DESCRIPTION

The IDs of each tire pressure warning valve and transmitters are registered

to the tire pressure warning

ECU.

When the IDs have never been registered, a DTC is output.

INSPECTION PROCEDURE

NOTICE:

When replacing the tire pressu ...