Toyota Sienna Service Manual: Removal

1. REMOVE FRONT EXHAUST PIPE ASSEMBLY

HINT: (See page EX-8)

2. REMOVE PROPELLER WITH CENTER BEARING SHAFT ASSEMBLY

HINT: (See page PR-3)

3. REMOVE REAR DIFFERENTIAL FILLER PLUG

(a) Using a hexagon wrench (10 mm), remove the filler plug and gasket.

4. REMOVE REAR DIFFERENTIAL DRAIN PLUG

(a) Using a hexagon wrench (10 mm), remove the drain plug and gasket, and drain the oil.

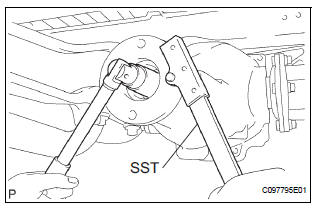

5. REMOVE REAR DRIVE PINION NUT

(a) Using a chisel and a hammer, unstake the staked part of the nut.

(b) Using SST to hold the flange, remove the nut.

SST 09330-00021

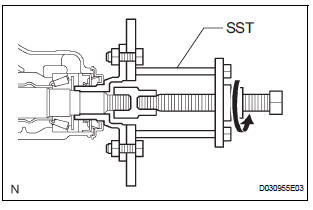

6. REMOVE REAR DRIVE PINION COMPANION FLANGE SUB-ASSEMBLY

(a) Using SST, remove the companion flange.

SST 09950-30012 (09951-03010, 09953-03010, 09954-03010, 09955-03030, 09956-03020)

7. REMOVE REAR DIFFERENTIAL CARRIER OIL SEAL

(a) Using SST, remove the oil seal.

SST 09308-10010

8. REMOVE REAR DIFFERENTIAL DRIVE PINION OIL SLINGER

9. REMOVE REAR DRIVE PINION FRONT TAPERED ROLLER BEARING

(a) Using SST, remove the front tapered roller bearing.

SST 09556-22010

10. REMOVE REAR DIFFERENTIAL DRIVE PINION BEARING SPACER

Rear differential carrier oil seal

Rear differential carrier oil seal

COMPONENTS

...

Installation

Installation

1. INSTALL REAR DIFFERENTIAL DRIVE PINION

BEARING SPACER

(a) Install a new bearing spacer.

2. INSTALL REAR DRIVE PINION FRONT TAPERED

ROLLER BEARING

(a) Install the tapered roller bearing.

3. IN ...

Other materials:

Precaution

1. INSPECTION PROCEDURE FOR VEHICLE INVOLVED

IN ACCIDENT

Perform the zero point calibration and sensitivity

check if any of the following conditions occur.

The occupant classification ECU is replaced.

Accessories (seatback tray and seat cover, etc.)

are installed.

...

Problem symptoms table

HINT:

If a normal code is displayed during the diagnostic trouble

code check although the trouble still occurs, check the

electrical circuits for each symptom in the order given in

the charts on the following pages and proceed to the page

given for troubleshooting.

The Matrix Chart is ...

Disassembly

1. REMOVE NO. 1ULTRASONIC SENSOR RETAINER

(w/ Clearance Sonar System) (See page PM-19)

2. REMOVE NO. 1 ULTRASONIC SENSOR (w/

Clearance Sonar System) (See page PM-19)

3. REMOVE REAR BUMPER ENERGY ABSORBER

4. REMOVE REAR BUMPER BAR PLATE

Remove the 4 clips and the rear bumper bar plate.

5. ...