Toyota Sienna Service Manual: Installation

1. INSTALL REAR DIFFERENTIAL DRIVE PINION BEARING SPACER

(a) Install a new bearing spacer.

2. INSTALL REAR DRIVE PINION FRONT TAPERED ROLLER BEARING

(a) Install the tapered roller bearing.

3. INSTALL REAR DIFFERENTIAL DRIVE PINION OIL SLINGER

(a) Install the oil slinger, as shown in the illustration.

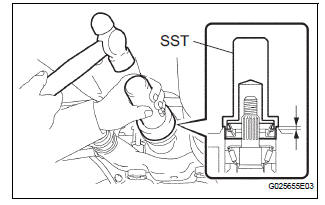

4. INSTALL REAR DIFFERENTIAL CARRIER OIL SEAL

(a) Using SST and a hammer, install a new oil seal.

SST 09554-22010 Oil seal drive in depth: 2.0 +- 0.3 mm (0.079 +- 0.012 in.)

(b) Coat MP grease to the oil seal lip.

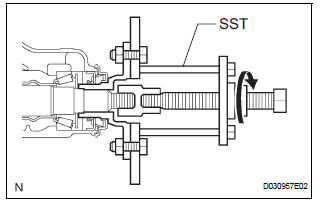

5. INSTALL REAR DRIVE PINION COMPANION FLANGE SUB-ASSEMBLY

(a) Using SST, install the companion flange on the shaft.

SST 09950-30012 (09951-03010, 09953-03010, 09954-03010, 09955-03030, 09956-03020)

NOTICE: Apply hypoid gear oil to the SST center bolt tip and threads before use.

6. INSTALL REAR DRIVE PINION NUT

(a) Coat the threads of a new nut with hypoid gear oil LSD.

(b) Using SST to hold the flange, torque the nut.

SST 09330-00021 Torque: 108 N*m (1,100 kgf*cm, 80 ft.*lbf)

7. INSPECT DIFFERENTIAL DRIVE PINION PRELOAD

(a) Inspect differential drive pinion preload (See page DF-31).

(b) Using a chisel and a hammer, stake the drive pinion nut.

8. INSTALL REAR DIFFERENTIAL DRAIN PLUG

(a) Using a hexagon wrench (10 mm), install the filler plug with a new gasket.

Torque: 49 N*m (500 kgf*cm, 36 ft.*lbf)

9. ADD DIFFERENTIAL OIL

(a) Fill the rear differential carrier assembly with hypoid gear oil.

10. INSPECT DIFFERENTIAL OIL

HINT: (See page DF-3)

11. INSTALL REAR DIFFERENTIAL FILLER PLUG

(a) Using a hexagon wrench (10 mm), install the filler plug with a new gasket.

Torque: 49 N*m (500 kgf*cm, 36 ft.*lbf)

12. INSTALL PROPELLER WITH CENTER BEARING SHAFT ASSEMBLY

(a) Install propeller with center bearing shaft assembly (See page PR-9).

(b) Fully tighten propeller with center bearing shaft assembly (See page PR-10).

13. INSTALL EXHAUST PIPE ASSEMBLY

HINT: (See page EX-10)

14. INSPECT FOR EXHAUST GAS LEAK

HINT: (See page EX-12)

Removal

Removal

1. REMOVE FRONT EXHAUST PIPE ASSEMBLY

HINT:

(See page EX-8)

2. REMOVE PROPELLER WITH CENTER BEARING

SHAFT ASSEMBLY

HINT:

(See page PR-3)

3. REMOVE REAR DIFFERENTIAL FILLER PLUG

(a) Using a hex ...

Rear differential carrier assembly

Rear differential carrier assembly

Components

...

Other materials:

How to proceed with

troubleshooting

HINT:

Use this procedure to troubleshoot the front power seat

control system.

The intelligent tester should be used in steps 3 and 5.

1 VEHICLE BROUGHT TO WORKSHOP

2 CUSTOMER PROBLEM ANALYSIS CHECK AND PROBLEM SYMPTOM CHECK

3 CHECK COMMUNICATION FUNCTION OF MULTIPLEX COMMUNI ...

Diagnosis system

1. CHECK DLC3

The ECU uses ISO 15765-4 for communication.

The terminal arrangement of the DLC3 complies

with SAE J1962 and meets the ISO 15765-4 format.

NOTICE:

*: Before measuring the resistance, leave the

vehicle as is for at least 1 minute and do not

operate the ignition s ...

On-vehicle inspection

1. INSPECT REAR AXLE HUB BEARING BACKLASH

(a) Using a dial gauge, check for backlash near the

center of the axle hub.

Maximum:

0.05 mm (0.0020 in.)

If backlash exceeds the maximum, replace the axle

hub assembly.

NOTICE:

Ensure that the dial gauge is set at right angles

to the measuremen ...