Toyota Sienna Service Manual: Reassembly

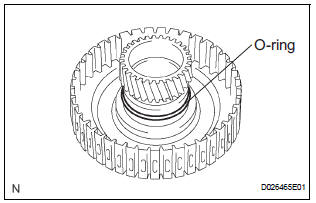

1. INSTALL UNDERDRIVE CLUTCH DRUM O-RING

(a) Coat a new O-ring with ATF, and install it to the underdrive clutch drum.

NOTICE: Make sure that the O-ring is not twisted or pinched.

2. INSTALL UNDERDRIVE CLUTCH PISTON SET

(a) Coat the underdrive clutch piston with ATF, and install it to the underdrive clutch piston drum.

NOTICE:

- Be careful not to damage the O-ring.

- Be careful not to damage the lip of the piston.

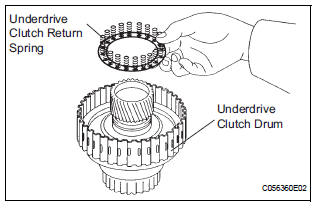

3. INSTALL UNDERDRIVE CLUTCH RETURN SPRING SUB-ASSEMBLY

(a) Install the return spring to the underdrive clutch drum.

NOTICE: Installing the spring sub-assembly, check that all of the springs are fit in the piston correctly.

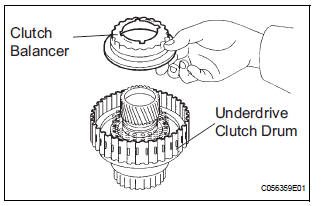

(b) Coat the clutch balancer with ATF.

(c) Install the clutch balancer to the underdrive clutch drum.

NOTICE: Be careful not to damage the lip of the clutch balancer.

(d) Place SST on the clutch balancer and compress the piston return spring with a press.

SST 09350-32014 (09351-32070)

(e) Using a snap ring expander, install the snap ring to the underdrive clutch drum.

(f) Be sure that the end gap of the snap ring is not aligned with the spring retainer claw.

NOTICE:

- Stop the press when the spring seat is lowered to the place 1 to 2 mm (0.039 to 0.078 in.) from the snap ring groove.

- This prevents the spring seat from being deformed

- Do not expand the snap ring excessively.

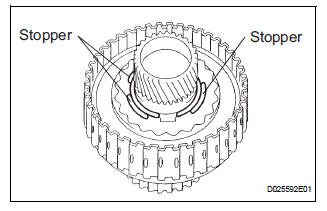

(g) Set the end gap of the snap ring in the underdrive clutch drum as shown in the illustration.

NOTICE: The end gap of the snap ring should not align with any of the stoppers.

4. INSTALL UNDERDRIVE CLUTCH DISC NO.1

(a) Coat the 4 discs with ATF.

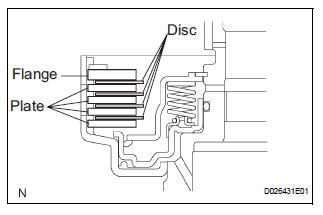

(b) Install the 4 plates, 4 discs and flange to the underdrive clutch drum.

NOTICE: Make sure that the plates, discs, and flange are installed as shown in the illustration.

5. INSTALL 1ST & REVERSE BRAKE RETURN SPRING SHAFT SNAP RING

(a) Using a screwdriver, install the underdrive clutch flange No.2 hole snap ring.

(b) Check that the end gap of snap ring is not aligned with one of the cutouts.

NOTICE: The snap ring should be fully engaged in the groove of the drum.

6. INSPECT UNDERDRIVE PACK CLEARANCE

HINT: (See page AX-262)

Inspection

Inspection

1. INSPECT UNDERDRIVE PACK CLEARANCE

(a) Install the underdrive clutch to the transaxle case.

NOTICE:

Be careful not to damage the oil seal rings.

(b) Install a dial indicator as shown in the ...

Differential case

Differential case

COMPONENTS

...

Other materials:

On-vehicle inspection

1. Check battery electrolyte level

(a) Check the electrolyte level.

(1) If the electrolyte level is low, replace the battery

(or add distilled water) and check the charging

system.

2. CHECK BATTERY SPECIFIC GRAVITY

(a) Check the color of the hydrometer.

Result

3. CHECK BATTERY VOLTAGE ...

ECM Power Source Circuit

DESCRIPTION

When the ignition switch is turned to the ON position, the battery voltage is

applied to terminal IGSW of

the ECM. The ECM MREL output signal causes a current to flow to the coil,

closing the contacts of the EFI

relay and supplying power to terminal +B of the ECM.

If the igniti ...

Air outlet control servo motor

ON-VEHICLE INSPECTION

1. INSPECT AIR OUTLET CONTROL SERVO MOTOR

(a) Remove the air outlet control servo motor.

(b) Connect the positive (+) lead from the battery to

terminal 4 and negative (-) lead to terminal 5, then

check that the lever turns to "DEF" position.

(c) Connect ...