Toyota Sienna Service Manual: Removal

1. REMOVE ENGINE ASSEMBLY WITH TRANSAXLE

HINT: See page EM-26

2. REMOVE OIL LEVEL GAUGE GUIDE SUBASSEMBLY (See page EM-39) 3. REMOVE NO. 1 OIL PIPE (See page EM-77) 4. REMOVE OIL PIPE (See page EM-77) 5. REMOVE CRANKSHAFT PULLEY (See page EM-79) 6. SEPARATE OIL COOLER PIPE

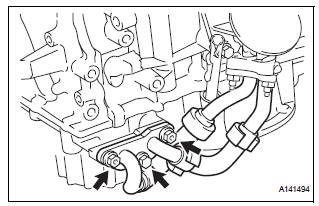

(a) Remove the bolt and 2 nuts, and disconnect the oil cooler pipe from the oil pan sub-assembly.

(b) Remove the gasket from the oil pan sub-assembly.

7. REMOVE WATER INLET HOUSING (See page CO-12) 8. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY (for Bank 1) (See page EM-82) 9. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY (for Bank 2) (See page EM-82) 10. REMOVE NO. 2 OIL PAN SUB-ASSEMBLY (See page EM-82) 11. REMOVE OIL STRAINER SUB-ASSEMBLY (See page EM-83) 12. REMOVE OIL PAN SUB-ASSEMBLY (See page EM- 83) 13. REMOVE TIMING CHAIN COVER SUB-ASSEMBLY

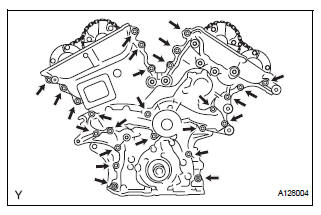

(a) Remove the 23 bolts and 2 nuts as shown in the illustration.

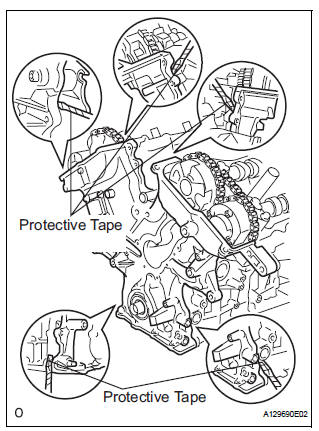

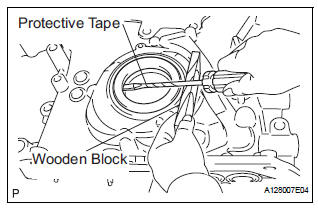

(b) Remove the timing chain cover by prying between the timing chain cover and cylinder head or cylinder block with a screwdriver.

| NOTICE: Be careful not to damage the contact surfaces of the cylinder head, cylinder block and chain cover. |

HINT: Tape the screwdriver tip before use.

(c) Remove the gasket.

14. REMOVE TIMING CHAIN CASE OIL SEAL

(a) Using a screwdriver, pry out the oil seal.

HINT: Tape the screwdriver tip before use.

Oil pump

Oil pump

Components

...

Disassembly

Disassembly

1. REMOVE OIL PUMP RELIEF VALVE

(A) using a 27 mm socket wrench, remove the relief

valve plug.

(B) remove the valve spring and oil pump relief valve.

2. REMOVE OIL PUMP COVER

(a) Remove ...

Other materials:

Bluetooth® Audio

Listening to Bluetooth® Audio

The Bluetooth® audio system enables the user to enjoy music

played on a portable player from the vehicle speakers via wireless

communication.

When a Bluetooth® device cannot be connected, check the connection

status on the “Bluetooth* Audio” screen. If the ...

Disassembly

1. REMOVE FRONT DIFFERENTIAL RING GEAR

(a) Place matchmarks on the front differential ring gear

and differential case.

(b) Remove the 14 bolts.

(c) Using a plastic hammer, tap on the front differential

ring gear to remove it from the case.

2. REMOVE FRONT DIFFERENTIAL CASE FRONT TA ...

Customize parameters

HINT:

The following items can be customized.

NOTICE:

After confirming whether the items requested by the

customer are applicable or not for customization,

perform customize operations.

Be sure to record the current settings before

customizing.

When troubleshooting, ...