Toyota Sienna Service Manual: Removal

1. DISCONNECT BATTERY NEGATIVE TERMINAL 2. REMOVE FRONT DOOR SCUFF PLATE LH HINT: (See page IP-6) 3. REMOVE FRONT DOOR SCUFF PLATE RH HINT: (See page IP-6) 4. REMOVE COWL SIDE TRIM BOARD LH HINT: (See page IP-6) 5. REMOVE COWL SIDE TRIM BOARD RH HINT: (See page IP-6) 6. REMOVE INSTRUMENT PANEL FINISH PANEL SUBASSEMBLY LOWER LH HINT: (See page IP-6) 7. REMOVE GLOVE COMPARTMENT DOOR STOPPER SUB-ASSEMBLY HINT: (See page IP-7) 8. REMOVE GLOVE COMPARTMENT DOOR ASSEMBLY HINT: (See page IP-7) 9. REMOVE FLOOR CARPET COVER CENTER LH HINT: (See page IP-8) 10. REMOVE FLOOR CARPET COVER CENTER RH HINT: (See page IP-8) 11. REMOVE INSTRUMENT CLUSTER FINISH PANEL CENTER NO.1 HINT: (See page IP-8) 12. REMOVE INSTRUMENT CLUSTER FINISH PANEL CENTER NO.2 HINT: (See page IP-8)

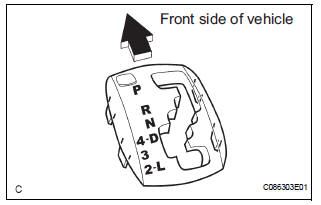

13. REMOVE SHIFT LEVER KNOB SUB-ASSEMBLY

(a) Remove the floor shift lever knob sub-assembly.

14. REMOVE POSITION INDICATOR HOUSING ASSEMBLY

(a) Using a screwdriver, remove the position indicator housing assembly from the instrument cluster finish panel assembly center.

15. REMOVE INSTRUMENT CLUSTER FINISH PANEL ASSEMBLY CENTER

HINT: (See page IP-9)

16. REMOVE SHIFT LEVER CAP

(a) Using a small screwdriver, remove the shift lever cap from the position indicator housing assembly.

17. REMOVE INSTRUMENT CLUSTER FINISH PANEL SUB-ASSEMBLY LOWER CENTER

HINT: (See page IP-9)

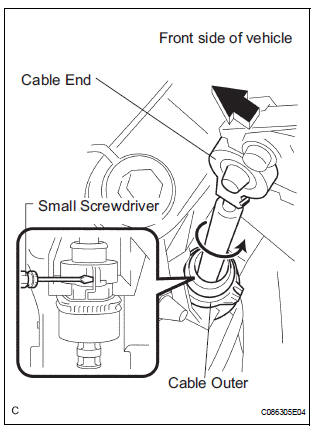

18. DISCONNECT TRANSMISSION CONTROL CABLE ASSEMBLY

(a) Using a screwdriver, disconnect the cable end from the shift lever assembly.

(b) Using a small screwdriver, disconnect the outer of transmission control cable assembly from the shift lever assembly.

19. REMOVE SHIFT LEVER ASSEMBLY

(a) Disconnect the 2 connectors.

(b) Remove the 4 bolts and disconnect the shift lever assembly from the vehicle.

Shift lever

Shift lever

Components

...

Disassembly

Disassembly

1. REMOVE INDICATOR LIGHT WIRE SUB-ASSEMBLY

(a) Remove the indicator light wire sub assembly from

the position indicator light guide.

2. REMOVE POSITION INDICATOR LIGHT BULB

(a) Remove the shi ...

Other materials:

Passenger Airbag ON/OFF Indicator Circuit

Malfunction

DTC B1152/28 Passenger Airbag ON/OFF Indicator Circuit

Malfunction

DESCRIPTION

The passenger airbag ON/OFF indicator circuit consists of the center airbag

sensor assembly and

passenger airbag ON/OFF indicator.

This circuit indicates the operation condition of the front passenger airbag,

t ...

Diagnostic trouble code chart

HINT:

If a trouble code is displayed during the DTC check, inspect

the circuit listed for that code. For details of each code, refer

to the relevant page listed under respective "DTC No." in the

DTC chart.

TIRE PRESSURE WARNING SYSTEM:

...

Terminals of ECM

1. SFI SYSTEM

HINT:

The standard normal voltage between each pair of the

ECM terminals is shown in the table below. The

appropriate conditions for checking each pair of the

terminals are also indicated.

The check results should be compared with the standard

normal voltage for that pair of ...