Toyota Sienna Service Manual: Repair

1. STEERING OFF CENTER REPAIR PROCEDURE

(a) Inspect steering wheel off center.

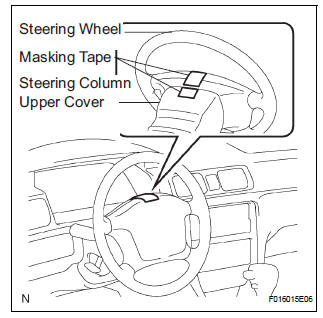

(1) Apply masking tape to the top center of the steering wheel and steering column upper cover.

(2) Drive the vehicle in a straight line for 100 meters at a constant speed of 35 mph (56 km/ h), and hold the steering wheel to maintain the course.

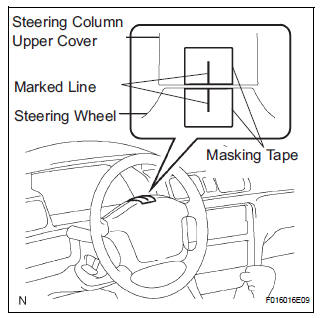

(3) Draw a line on the masking tape as shown in the illustration.

(4) Turn the steering wheel to its straight position.

HINT: Refer to the upper surface of the steering wheel, steering spoke and SRS airbag line for the straight position.

(5) Draw a new line on the masking tape or the steering wheel as shown in the illustration.

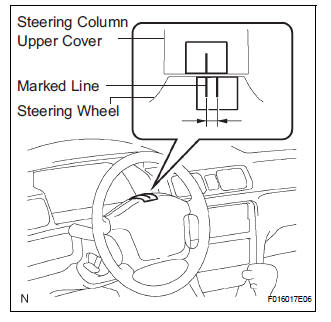

(6) Measure the distance between the 2 lines on the masking tape of the steering wheel.

(7) Convert the measured distance to steering angle.

HINT:

- Measured distance 1 mm (0.04 in.) = Steering angle approximately 1 deg.

- Make a note of the steering angle.

(b) Adjust the steering angle.

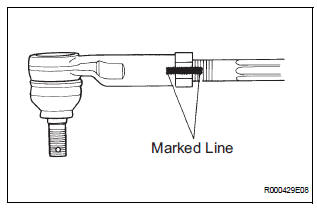

(1) Draw a line on the RH and LH tie rod and on the RH and LH rack end, which can easily be seen.

(2) Using a paper gauge, measure the distance from the RH and LH tie rod ends to the rack end screws.

HINT:

- Measure the RH side and LH side.

- Make a note of the measured values.

(3) Remove the RH and LH boot clips from the rack boots.

(4) Loosen the RH and LH lock nuts.

(5) Turn the RH and LH rack end by the same amount (but in different directions) according to the steering angle.

HINT: 1 turn 360 deg. of rack end (1.5 mm (0.059 in.) horizontal movement) - 12 deg. of steering angle.

(6) Tighten the RH and LH lock nuts.

Torque: 74 N*m (755 kgf*cm, 55 ft.*lbf)

NOTICE:

Make sure that the difference in length between RH and LH tie rod ends and rack end screws are within 1.5 mm (0.059 in.).

(7) Install the RH and LH boot clips.

On-vehicle Inspection

On-vehicle Inspection

1. CHECK STEERING WHEEL FREEPLAY

(a) Stop the vehicle and face the tires straight ahead.

(b) Rock the steering wheel gently up and down with

your hand, check the steering wheel freeplay.

Max ...

Steering Column Assembly

Steering Column Assembly

COMPONENTS

...

Other materials:

Removal

HINT:

Replace the RH side by the same procedures as the LH side.

1. REMOVE REAR WHEEL

2. REMOVE REAR AXLE SHAFT LH NUT (See page DS-

22)

3. SEPARATE REAR DISC BRAKE CALIPER

ASSEMBLY LH

(a) Removing the 2 bolts, separate the rear disc brake

caliper assembly LH.

4. REMOVE REAR DISC

5. SEPARA ...

Removal

1. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

2. REMOVE REAR NO. 2 SEAT LEG SIDE GARNISH SUB-ASSEMBLY

Disengage the 9 clips and remove the rear No. 2

seat leg side garnish sub-assembly.

Remove the 9 clips from the rear No. 2 seat leg side

garnish sub-assembly.

3. ...

Removal

1. BOLT, SCREW AND NUT TABLE

The bolts, the screws and the nuts, which are

necessary for installation and removal of the

instrument panel are shown in the illustration below

with alphabets.

2. DISCONNECT BATTERY NEGATIVE TERMINAL

3. REMOVE STEERING WHEEL COVER LOWER NO.2

4. ...