Toyota Sienna Service Manual: Stereo Component Amplifier Communication Error

INSPECTION PROCEDURE

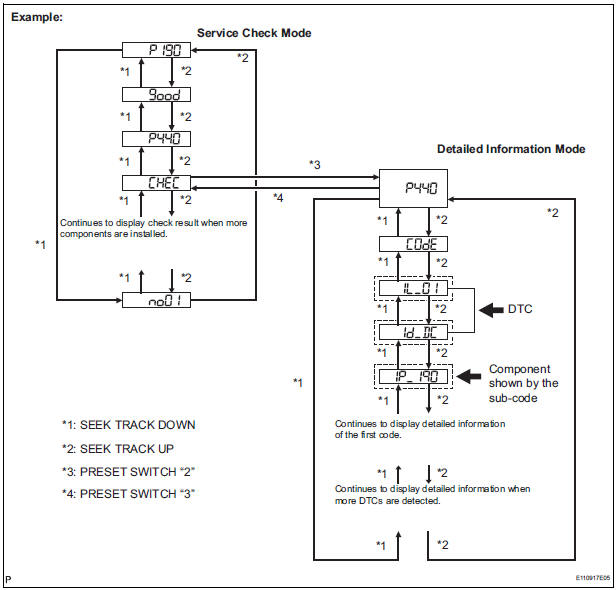

1 IDENTIFY THE COMPONENT SHOWN BY THE SUB-CODE

- Enter the diagnostic mode.

- Press the preset switch "3" to change to "Detailed Information Mode".

- Identify the component shown by the sub-code.

HINT:

- "190 (radio receiver)" is the component shown by the subcode in the example shown in the illustration.

- For details of the DTC display, refer to "DTC CHECK/ CLEAR"

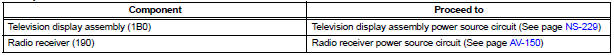

2 CHECK POWER SOURCE CIRCUIT OF COMPONENT SHOWN BY SUB-CODE

- Inspect the power source circuit of the component shown

by the sub-code.

If the power source circuit is operating normally, proceed to the next step

Component Table:

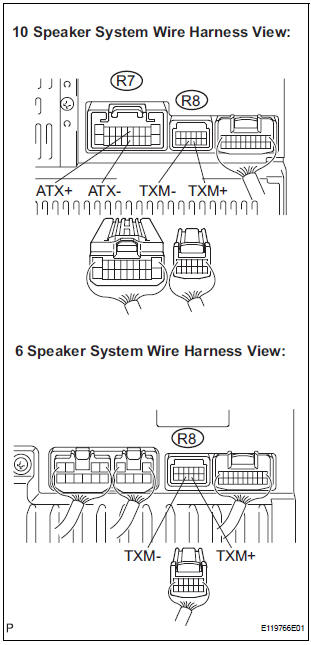

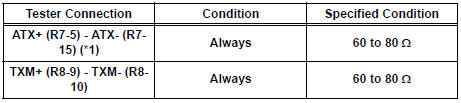

3 INSPECT RADIO RECEIVER

- Disconnect the radio receiver connectors.

- Measure the resistance according to the value(s) in the table below.

Standard resistance

*1: 10 Speaker System

4 CHECK HARNESS AND CONNECTOR (STEREO COMPONENT AMPLIFIER -COMPONENT SHOWN BY SUB-CODE)

HINT:

- Start the check from the circuit that is near the component shown by the sub-code first.

- For details of the connectors, refer to the "TERMINALS OF ECU".

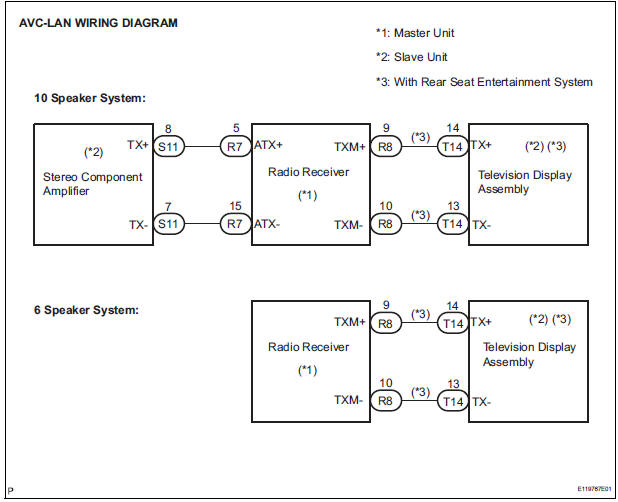

- Referring to the AVC-LAN wiring diagram below, check the AVC-LAN circuit between the stereo component amplifier and the component shown by the sub-code.

- Disconnect all connectors between the stereo component amplifier and the component shown by sub-code.

- Check for an open or short in the AVC-LAN circuit between the stereo component amplifier and the component shown by the sub-code.

OK: There is no open or short circuit.

5 REPLACE COMPONENT SHOWN BY SUB-CODE

- Replace the component shown by the sub-code with a normal one and check if the same problem occurs again.

OK: Same problem does not occur

END

Radio Receiver Communication Error

Radio Receiver Communication Error

INSPECTION PROCEDURE

1 IDENTIFY THE COMPONENT SHOWN BY THE SUB-CODE

Enter the diagnostic mode

Press the preset switch "3" to change to "Detailed

Information Mode". ...

Television Display Assembly Communication Error

Television Display Assembly Communication Error

INSPECTION PROCEDURE

1 IDENTIFY THE COMPONENT SHOWN BY THE SUB-CODE

Enter the diagnostic mode.

Press the preset switch "3" to change to "Detailed

Information Mode" ...

Other materials:

Front Occupant Classification Sensor RH Circuit

Malfunction

DTC B1781 Front Occupant Classification Sensor RH Circuit

Malfunction

DESCRIPTION

The front occupant classification sensor RH circuit consists of the occupant

classification ECU and the

front occupant classification sensor RH.

DTC B1781 is recorded when a malfunction is detected in the fron ...

Reassembly

1. INSTALL FRONT DISC

(a) Aligning the matchmarks, install the front disc.

HINT:

Select the installation position where the disc has

the minimum runout.

2. INSPECT DISC RUNOUT

(a) Temporarily fasten the disc with the hub nuts.

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

(b) Using a ...

Installation

1. INSTALL CENTER AIRBAG SENSOR ASSEMBLY

Check that the ignition switch is off.

Check that the battery negative (-) terminal is

disconnected.

CAUTION:

After disconnecting the negative battery

terminal, wait for at least 90 seconds before

starting the operation.

&n ...