Toyota Sienna Service Manual: Radio Receiver Communication Error

INSPECTION PROCEDURE

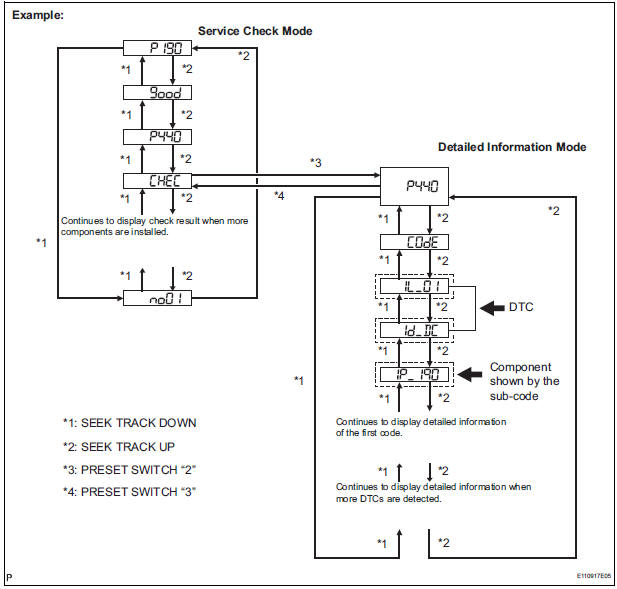

1 IDENTIFY THE COMPONENT SHOWN BY THE SUB-CODE

- Enter the diagnostic mode

- Press the preset switch "3" to change to "Detailed Information Mode".

- Identify the component shown by the sub-code.

HINT:

- "190 (radio receiver)" is the component shown by the subcode in the example shown in the illustration.

- For details of the DTC display, refer to "DTC CHECK/ CLEAR"

2 CHECK POWER SOURCE CIRCUIT OF COMPONENT SHOWN BY SUB-CODE

- Inspect the power source circuit of the component shown

by the sub-code.

If the power source circuit is operating normally, proceed to the next step.

Component Table:

|

Component |

Proceed to |

| Stereo component amplifier (440) | Stereo component amplifier power source circuit |

| Television display assembly (1B0) | Television display assembly power source circuit |

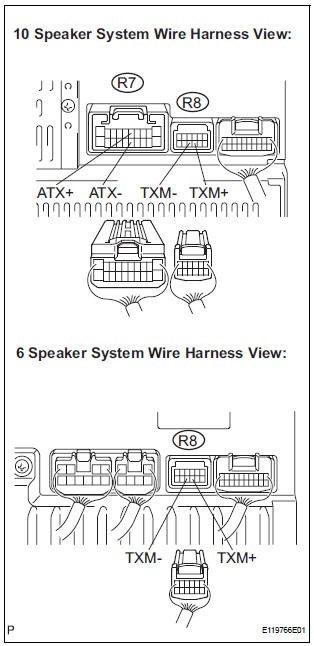

3 INSPECT RADIO RECEIVER

- Disconnect the radio receiver connectors.

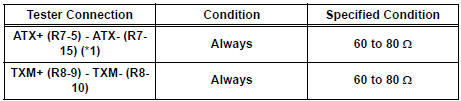

- Measure the resistance according to the value(s) in the table below.

Standard resistance

*1: 10 Speaker System

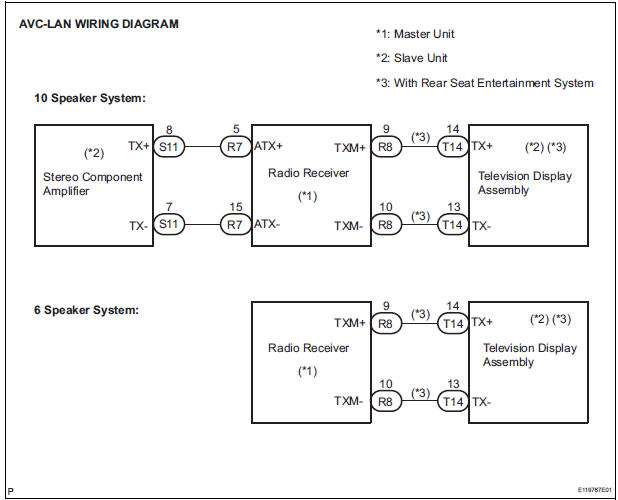

4 CHECK HARNESS AND CONNECTOR (RADIO RECEIVER - COMPONENT SHOWN BY SUB-CODE)

HINT:

- Start the check from the circuit that is near the component shown by the sub-code first.

- For details of the connectors, refer to the "TERMINALS OF ECU".

- Referring to the AVC-LAN wiring diagram below, check the AVC-LAN circuit between the radio receiver and the component shown by the sub-code.

- Disconnect all connectors between the radio receiver and the component shown by sub-code.

- Check for an open or short in the AVC-LAN circuit between the radio receiver and the component shown by the sub-code.

OK: There is no open or short circuit.

5 REPLACE COMPONENT SHOWN BY SUB-CODE

- Replace the component shown by the sub-code with a normal one and check if the same problem occurs again.

OK: Same problem does not occur.

END

Vehicle Speed Signal Circuit between Stereo Component Amplifier and

Combination Meter

Vehicle Speed Signal Circuit between Stereo Component Amplifier and

Combination Meter

DESCRIPTION

This circuit is necessary for the ASL (Auto Sound Leveliser) built into the

stereo component amplifier.

Speed signals are received from the combination meter and used for the ASL.

...

Stereo Component Amplifier Communication Error

Stereo Component Amplifier Communication Error

INSPECTION PROCEDURE

1 IDENTIFY THE COMPONENT SHOWN BY THE SUB-CODE

Enter the diagnostic mode.

Press the preset switch "3" to change to "Detailed

Information Mode" ...

Other materials:

Reassembly

1. INSTALL COOLER DRYER

(a) Using needle nose pliers, install the cooler dryer.

(b) Install a new O-ring on the cap.

(c) Sufficiently apply compressor oil to the fitting

surfaces of the O-ring and the cap.

Compressor oil:

ND-OIL 8 or equivalent

(d) Using a hexagon wrench 14 mm ( ...

Transmission Error

DTC 01-DC Transmission Error

DESCRIPTION

HINT:

*1: This code may be stored if the engine is started, idled for 60 seconds and

then started again.

NOTICE:

Before starting troubleshooting, be sure to clear DTCs to erase

codes stored due to the

reasons described in the HINT ...

Data list / active test

1. READ DATA LIST

HINT:

Using the intelligent tester to read the Data List allows

the values or states of switches, sensors, actuators and

other items to be read without removing any parts. This

non-intrusive inspection can be very useful because

intermittent conditions or signals may be disco ...