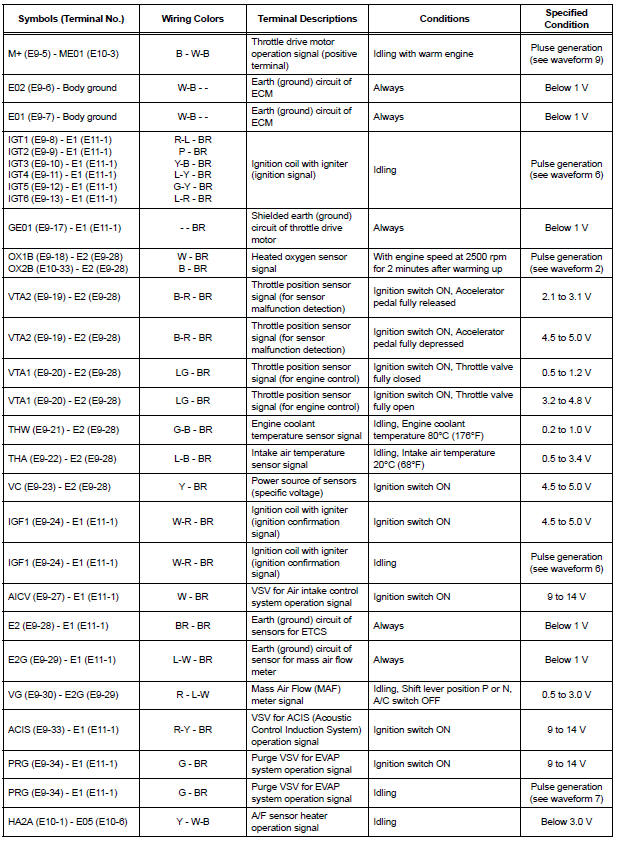

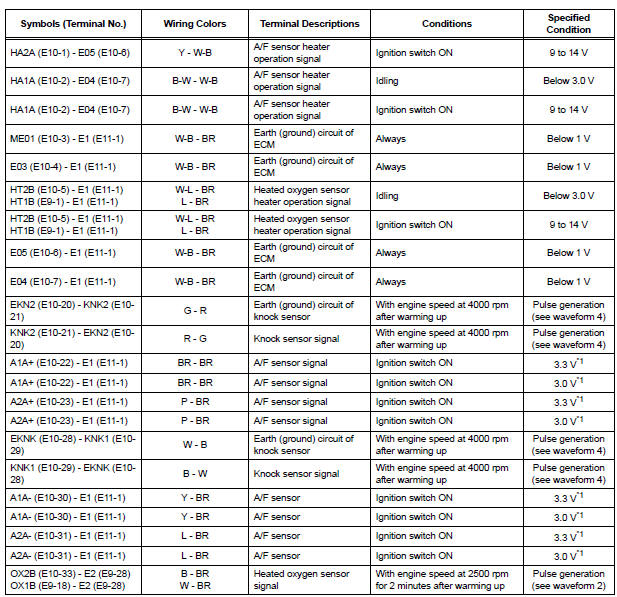

Toyota Sienna Service Manual: Terminals of ecm

Sfi system

Hint:

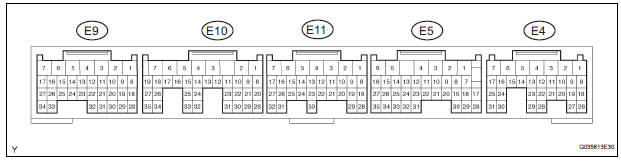

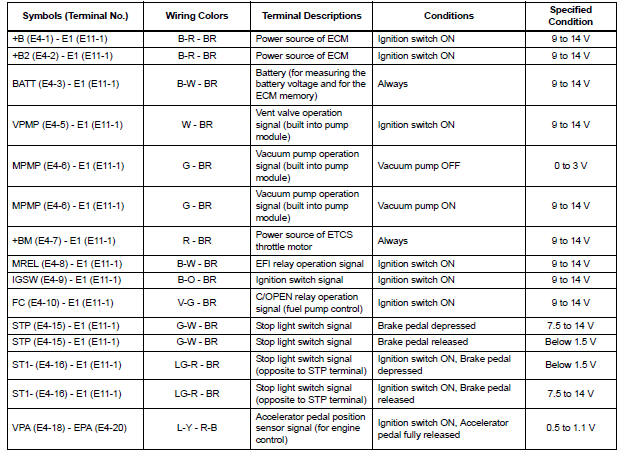

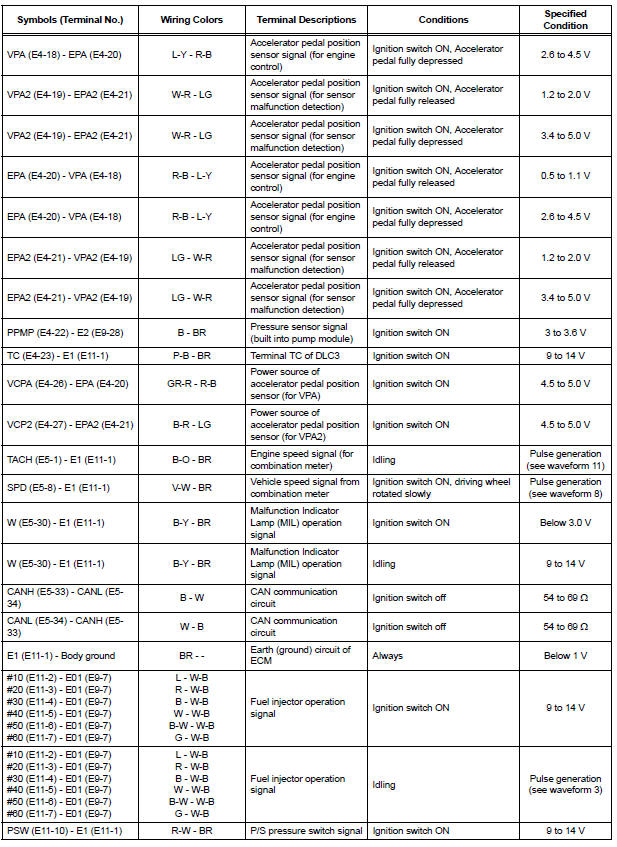

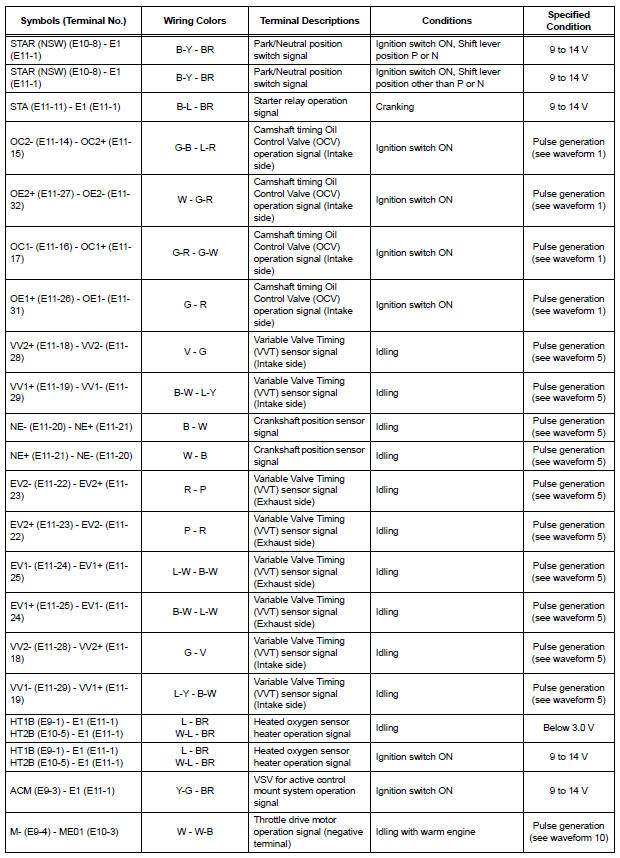

The standard normal voltage between each pair of the ECM terminals is shown in the table below. The appropriate conditions for checking each pair of the terminals are also indicated.

The check results should be compared with the standard normal voltage for that pair of terminals, listed in the "Specified Condition" column.

The illustration above can be used as a reference to identify the ECM terminal locations.

*1: The ECM terminal voltage is constant regardless of the output voltage from the sensor.

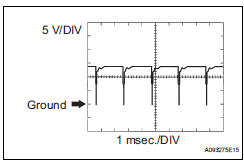

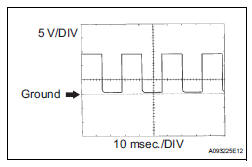

(a) WAVEFORM 1

(1) Camshaft Timing Oil Control Valve (OCV)

operation signal

HINT:

The wavelength becomes shorter as the engine rpm increases.

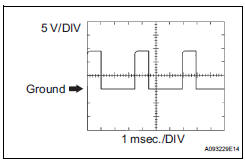

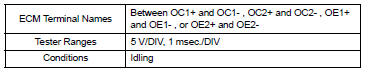

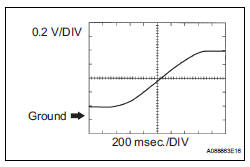

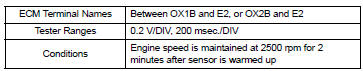

(b) WAVEFORM 2

(1) Heated oxygen sensor signal

HINT:

In the DATA LIST, item O2S B1S2 shows the ECM input values from the heated oxygen sensor.

(c) WAVEFORM 3

(1) Fuel injector operation signal

HINT:

The wavelength becomes shorter as the engine rpm increases.

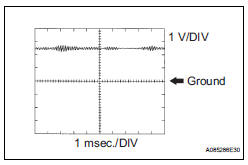

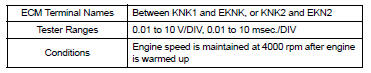

(d) WAVEFORM 4

(1) Knock sensor signal

HINT:

- The wavelength becomes shorter as the engine rpm increases.

- The waveforms and amplitudes displayed differ slightly depending on the vehicle.

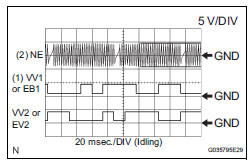

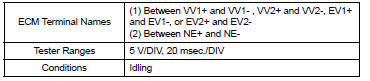

(e) WAVEFORM 5

(1) Variable Valve Timing (VVT) sensor signal (1)

(2) Crankshaft position sensor signal (2)

HINT:

The wavelength becomes shorter as the engine rpm increases.

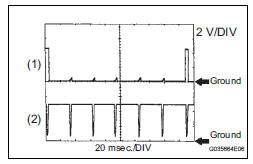

(f) WAVEFORM 6

(1) Igniter IGT signal (from ECM to igniter) (1)

(2) Igniter IGF signal (from igniter to ECM) (2)

HINT:

The wavelength becomes shorter as the engine rpm increases.

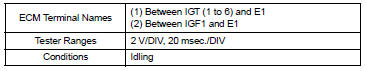

(g) WAVEFORM 7

(1) Purge VSV for EVAP system operation signal

HINT:

If the waveform is not similar to that shown in the illustration, check the waveform again after idling for 10 minutes or more.

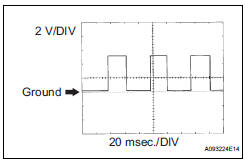

(h) WAVEFORM 8

(1) Vehicle speed signal

HINT:

- The wavelength becomes shorter as the vehicle speed increases.

- Depending on the vehicle, the output waveform voltage may rise to 12 V if influenced by optionally installed systems.

(i) WAVEFORM 9

(1) Throttle drive motor operation signal (positive

terminal)

HINT:

The duty ratio varies depending on the throttle actuator operation.

(j) WAVEFORM 10

(1) Throttle drive motor operation signal (negative

terminal)

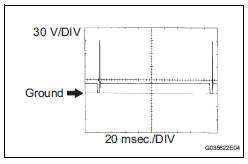

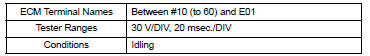

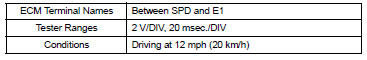

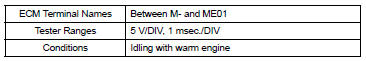

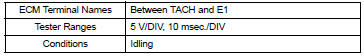

(k) WAVEFORM 11

1) Engine speed signal

HINT:

The wavelength becomes shorter as the engine rpm increases.

Problem symptoms table

Problem symptoms table

HINT:

When a malfunction is not confirmed by a DTC (Diagnostic

Trouble Code) check and the cause of problem cannot be

identified through a basic inspection, troubleshoot according

to the priority ...

Diagnosis system

Diagnosis system

DESCRIPTION

(a) When troubleshooting OBD II (On-Board

Diagnostics) vehicles, an intelligent tester

(complying with SAE J1987) must be connected to

the DLC3 (Data Link Connector 3) of the vehicle.

...

Other materials:

Inspection

1. INSPECT REAR SPEED SENSOR

(a) Disconnect the skid control sensor connector.

(b) Measure the resistance between terminals 1 and 2

of the skid control sensor connector.

OK:

Resistance:

less than 2.2 kΩ

(c) Measure resistance between each of terminals 1

and 2 of the skid control s ...

Fuel information

You must only use unleaded gasoline in your vehicle.

Select octane rating 87 (Research Octane Number 91) or higher.

Use of unleaded gasoline with an octane rating lower than 87

may result in engine knocking. Persistent knocking can lead to

engine damage.

At minimum, the gasoline you use s ...

Perform monitor drive pattern

The monitor results and test values can be checked with

the OBD II scan tool or the intelligent tester. The engine

control module (ECM) monitors the emissions-related

components such as the thermostat, catalyst converter

and evaporative emissions (EVAP), and determines

whether they are function ...