Toyota Sienna Service Manual: Unlock Warning Switch Circuit

DESCRIPTION

The unlock warning switch detects if the key is in the ignition key cylinder.

The unlock warning switch turns on when the key is inserted into the ignition key cylinder and turns off when the key is removed from the cylinder.

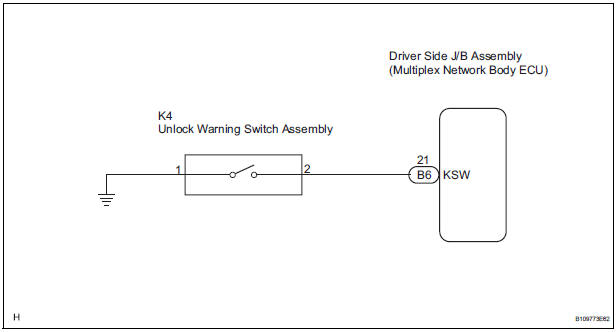

The body ECU is connected to the unlock warning switch via terminal KSW and key detection status signals are input to the ECU.

The body ECU applies voltage to the unlock warning switch via terminal KSW. When the unlock warning switch is on (there is continuity between the switch terminals), a signal indicating that the key is in the ignition key cylinder is input to the body ECU. When the switch is off (there is no continuity between the switch terminals), a signal indicating that the key is not in the cylinder is input.

WIRING DIAGRAM

INSPECTION PROCEDURE

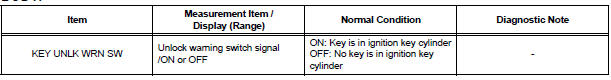

1 READ VALUE OF DATA LIST (UNLOCK WARNING SWITCH)

- Check the DATA LIST to ensure proper function of the door unlock detection switch.

BODY:

OK: The display is as specified in the normal condition.

PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS TABLE

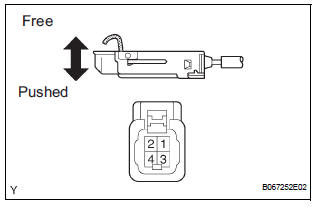

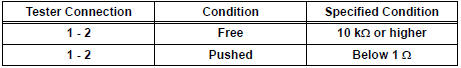

2 INSPECT UNLOCK WARNING SWITCH ASSEMBLY

- Remove the unlock warning switch assembly.

- Measure the resistance according to the value(s) in the table below.

Standard resistance

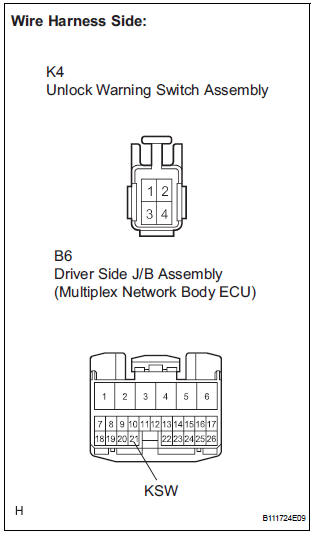

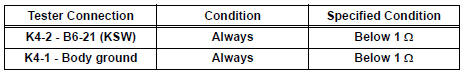

3 CHECK WIRE HARNESS (UNLOCK WARNING SWITCH - DRIVER SIDE J/B)

- Disconnect the K4 unlock warning switch assembly connector.

- Disconnect the B6 driver side J/B connector.

- Measure the resistance according to the value(s) in the table below.

Standard resistance

PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS TABLE

Data list / active test

Data list / active test

1. READ DATA LIST

HINT:

Using the intelligent tester's DATA LIST allows switch,

actuator and other item values to be read without

removing any parts. Reading the DATA LIST early in

troubleshootin ...

Transmitter battery

Transmitter battery

REPLACEMENT

1. REMOVE TRANSMITTER BATTERY

NOTICE:

Special caution should be taken for handling each

component as they are precision electronic

components.

Using a coin or the equiva ...

Other materials:

Throttle / Pedal Position Sensor/ Switch

DTC P2120 Throttle / Pedal Position Sensor / Switch "D"

Circuit

DTC P2122 Throttle / Pedal Position Sensor / Switch "D"

Circuit Low Input

DTC P2123 Throttle / Pedal Position Sensor / Switch "D"

Circuit High Input

DTC P2125 Throttle / Pedal Position Sensor / Switch ...

AVC-LAN Circuit

DESCRIPTION

Each unit of the audio system connected to the AVC-LAN (communication bus)

transfers the signal of

each switch by communication.

When a short to +B or short to ground occurs in this AVC-LAN, the audio system

will not function normally

as the communication is discontinued.

INSP ...

Reassembly

NOTICE:

Before installation, coat the parts indicated by arrows

with power steering fluid (See page PS-7).

1. INSTALL VANE PUMP HOUSING OIL SEAL

(a) Coat a new vane pump housing oil seal lip with

power steering fluid.

(b) Using SST and a press, install the vane pump

housing oil seal until i ...