Toyota Sienna Service Manual: When servicing full-time 4wd vehicles

The full-time 4WD SIENNA is equipped with the open center differential system.

If incorrect preparations or test procedures are used, the test will not only be unsuccessful, but may be dangerous as well.

Therefore, before beginning any such servicing or test, be sure to check the following items:

- Whether wheels should be touching ground or jacked up

- Transaxle gear position

- Maximum testing vehicle speed

- Maximum testing time

(a) Before Beginning Test

This vehicle does not have a center diff. lock mode or 4WD (Normal) Mode to allow only the front or rear wheel to be rotated.

The test method for this vehicle is different from that for vehicles equipped with the center diff. lock mode or 4WD (Normal) Mode, so make sure to use the correct test method.

Braking Force Test

Braking Force Test

(Vehicle Speed: Below 0.5 km/h or 0.3 mph) When performing low-speed type brake tester measurements, observe the following instructions.

(1) Position the wheels to be tested (front or rear) on the tester.

(2) Shift the transaxle shift lever to "N" position.

(3) Idle the engine, operate the brake booster and perform the test.

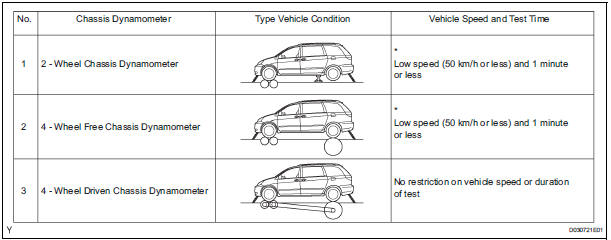

(c) Speedometer Test or Other Tests

(Using Speedometer Tester or Chassis Dynamometer)

When performing test at high speed or high load, use the methods shown below.

*: This is to avoid damaging the center differential.

(d) On-Vehicle Wheel Balancing

On-Vehicle Wheel Balancing

When doing on-vehicle wheel balancing on a fulltime 4WD vehicle, to prevent the wheels from rotating at different speeds in different directions from each other (which could damage the center differential), always be sure to observe the following precautions:

(1) All 4 wheels should be jacked up, clearing the ground completely.

(2) The parking brake lever should be fully released.

(3) None of the brakes should be allowed to drag.

(4) The wheels should be driven on the wheel balancer with the engine running.

HINT:

When doing this, be careful of the other wheels, which will rotate at the same time.

(5) Avoid sudden acceleration, deceleration and braking.

(6) Carry out wheel balancing with the transaxle in D position.

For vehicles equipped with mobile communication systems

For vehicles equipped with mobile communication systems

FOR VEHICLES EQUIPPED WITH MOBILE COMMUNICATION SYSTEMS

(a) Install the antenna far away from the ECU and

sensors of the vehicle electronic systems as

possible.

(b) Install an antenna feeder ...

For vehicles equipped with traction control (trac) system

For vehicles equipped with traction control (trac) system

When using a 2-wheel drum tester such as a

speedometer tester or chassis dynamometer, etc., or

jacking up the front wheels and driving the wheels,

always push in the TRAC cut ("TRAC OFF") ...

Other materials:

Installation

1. INSTALL FRONT SEAT ASSEMBLY LH

Place the seat assembly in the cabin.

NOTICE:

Be careful not to damage the body.

Connect the connectors under the seat assembly.

Tighten the 2 bolts on the front side of the seat

assembly.

Torque: 37 N*m (375 kgf*cm, 27 ft.*lb ...

Open in Side Squib LH Circuit

DTC B0116/48 Open in Side Squib LH Circuit

DESCRIPTION

The side squib LH circuit consists of the center airbag sensor assembly and

the front seat side assembly

LH.

This circuit instructs the SRS to deploy when deployment conditions are met.

DTC B0116/48 is recorded when an open circuit is ...

Diagnosis Circuit

DESCRIPTION

DTC output mode is set by connecting terminals TC and CG of the DLC3.

DTCs are displayed by blinking the SRS warning light.

HINT:

When each warning light stays blinking, a ground short in the

wiring of terminal TC of the DLC3 or an

internal ground short in each ECU is ...