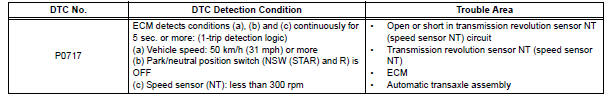

Toyota Sienna Service Manual: Turbine Speed Sensor Circuit No Signal

DESCRIPTION

This sensor detects the rotation speed of the input turbine. By comparing the input turbine speed signal (NT) with the counter gear speed sensor signal (NC), the ECM detects the shift timing of the gears and appropriately controls the engine torque and hydraulic pressure according to various conditions. Thus, providing smooth gear shift.

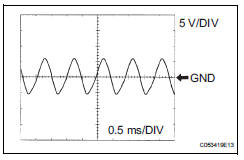

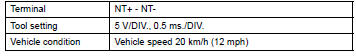

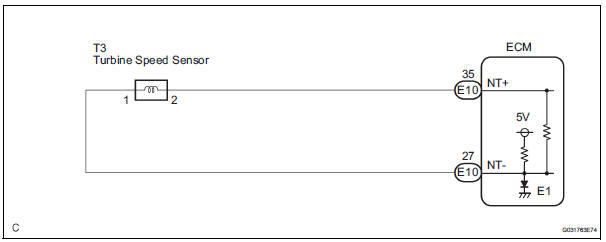

Reference (Using an oscilloscope): Check the waveform between terminals NT+ and NT- of the ECM connector.

Standard: Refer to the illustration.

MONITOR DESCRIPTION

The NT terminal of the ECM detects a revolution signal from the speed sensor (NT) (input RPM). The ECM calculates a gearshift comparing the speed sensor (NT) with the speed sensor (NC).

While the vehicle is operating in 2nd, 3rd, 4th or 5th gear in the shift position of D, if the input shaft revolution is less than 300 rpm *1although the output shaft revolution is more than 1,000 rpm *2, the ECM detects the trouble, illuminates the MIL and stores the DTC.

*1: Pulse is not output or is irregularly output.

*2: The vehicle speed is 50 km/h (31 mph) or more.

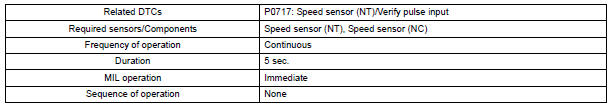

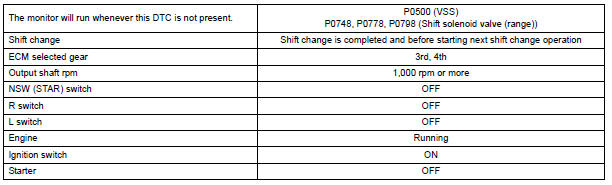

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

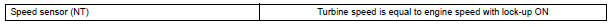

TYPICAL MALFUNCTION THRESHOLDS

COMPONENT OPERATING RANGE

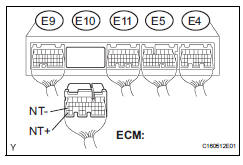

WIRING DIAGRAM

INSPECTION PROCEDURE

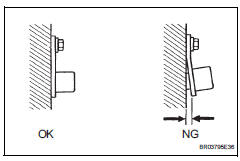

1 INSPECT SPEED SENSOR INSTALLATION

(a) Check the speed sensor installation.

OK: The installation bolt is tightened properly and there is no clearance between the sensor and transaxle case.

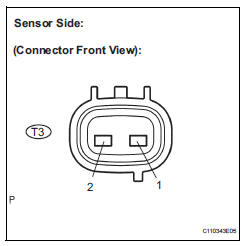

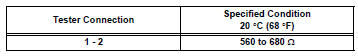

2 INSPECT SPEED SENSOR (NT)

(a) Disconnect the speed sensor connector from the transaxle.

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

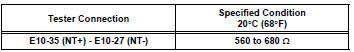

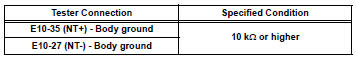

3 CHECK HARNESS AND CONNECTOR (SPEED SENSOR - ECM)

(a) Connect the speed sensor connector.

(b) Disconnect the ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard resistance

(d) Measure the resistance according to the value(s) in the table below.

Standard resistance (Check for short)

REPLACE ECM

Transmission Fluid Temperature Sensor "A"

Performance

Transmission Fluid Temperature Sensor "A"

Performance

DESCRIPTION

The ATF (Automatic Transmission Fluid) temperature sensor converts the fluid

temperature into a

resistance value which is input into the ECM.

MONITOR DESCRIPTION

The ATF temp ...

Brake Switch "B" Circuit High

Brake Switch "B" Circuit High

DESCRIPTION

The purpose of this circuit is to prevent the engine from stalling while

driving in lock-up condition when

brakes are suddenly applied.

When the brake pedal is depressed, this s ...

Other materials:

Installation

1. INSTALL FRONT DOOR GLASS WEATHERSTRIP

Install the front door grass weatherstrip.

2. INSTALL OUTER REAR VIEW MIRROR ASSEMBLY

(See page MI-45)

3. INSTALL FRONT DOOR TRIM BOARD SUBASSEMBLY

4. INSTALL POWER WINDOW REGULATOR MASTER

SWITCH ASSEMBLY

5. INSTALL BACK FRAME PLATE

6. INSTALL FR ...

Data list / active test

1. USING INTELLIGENT TESTER

Connect the intelligent tester to the DLC3.

Monitor the ECU data by following the prompts on

the tester screen.

HINT:

The intelligent tester has a "Snapshot" function

which records the monitored data. Refer to the

intelligent tester ope ...

Absence of Registration Unit/ No Response for Connection Check/ Last Mode

Error/ No Response Against ON / OFF Command/ Mode Status Error/ Slave Reset

DESCRIPTION

HINT:

*1: Even if no fault is present, this trouble code may be stored

depending on the battery condition or

engine start voltage.

*2: If the power connector is disconnected after the engine

starts, this code is stored after 180 seconds.

*3: If the ...