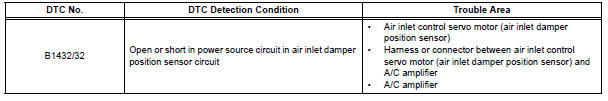

Toyota Sienna Service Manual: Air Inlet Damper Position Sensor Circuit

DESCRIPTION

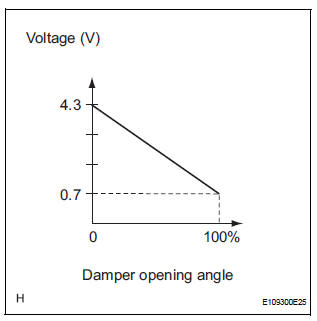

This sensor detects the position of the air inlet control servo motor and sends the appropriate signals to the A/C amplifier. The position sensor is built in the air inlet control servo motor.

The position sensor's resistance changes as the air inlet control servo motor arm moves.

It outputs voltage (5 V) that is input to terminal 1 and terminal 3 via the variable resistor, and then to the A/ C amplifier.

The A/C amplifier determines the arm position based on the input voltage from

the position sensor.

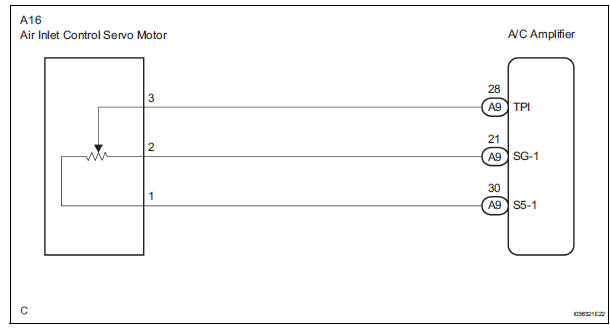

WIRING DIAGRAM

INSPECTION PROCEDURE

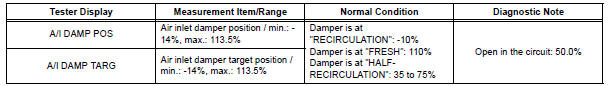

1 READ VALUE OF INTELLIGENT TESTER

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the intelligent tester main switch on.

(c) Select the items below in the DATA LIST, and read the display on the intelligent tester.

DATA LIST / AIR CONDITIONER

OK: The display is as specified in the normal condition column.

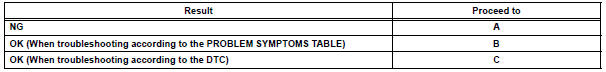

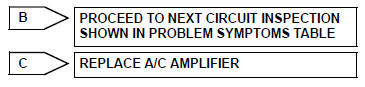

Result

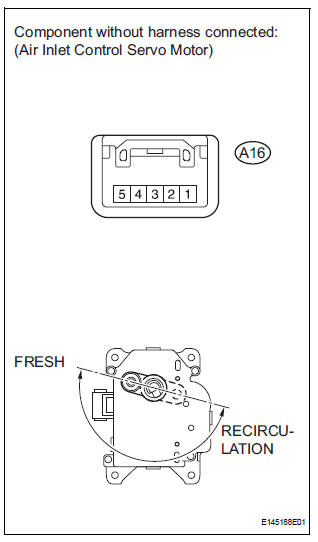

2 INSPECT AIR INLET CONTROL SERVO MOTOR

(a) Remove the air inlet control servo motor.

(b) Disconnect the connector from the air inlet control servo motor.

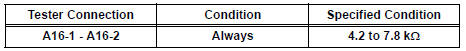

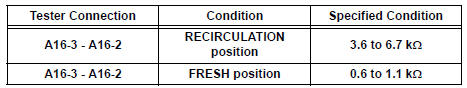

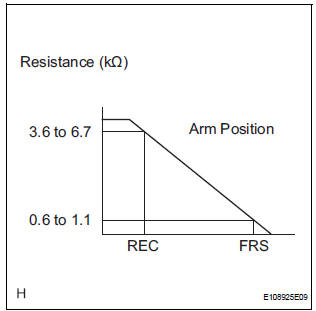

(c) Measure the resistance according to the value(s) in the table below.

Standard resistance

(d) Measure the resistance according to the value(s) in the table below.

Standard resistance

(e) As the air inlet control servo motor moves from RECIRCULATION to FRESH, the resistance decreases gradually without interruption.

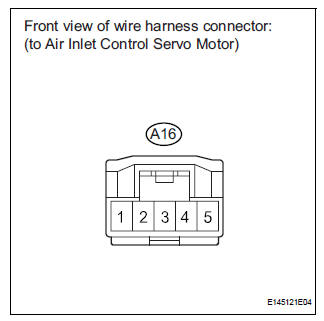

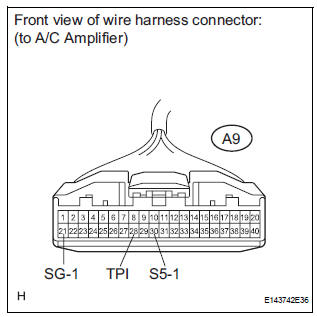

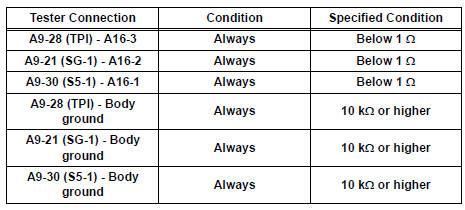

3 CHECK HARNESS AND CONNECTOR (AIR INLET CONTROL SERVO MOTOR - A/C AMPLIFIER)

(a) Disconnect the connector from the A/C amplifier.

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

Standard resistance

Air Mix Damper Position Sensor Circuit (Passenger Side)

Air Mix Damper Position Sensor Circuit (Passenger Side)

DESCRIPTION

This sensor detects the position of the air mix control servo motor (air mix

damper) and sends the

appropriate signals to the A/C amplifier. The position sensor is built in the

a ...

Air Outlet Damper Position Sensor Circuit

Air Outlet Damper Position Sensor Circuit

DESCRIPTION

This sensor detects the position of the air outlet control servo motor and

sends the appropriate signals to

the A/C amplifier. The position sensor is built in the air outlet contro ...

Other materials:

Disassembly

1. REMOVE FRONT SEAT SIDE TABLE LEG COVER (w/

Table)

Using a screwdriver, disengage the claws and

remove the seat side table leg cover.

HINT:

Tape the screwdriver tip before use.

2. REMOVE FRONT SEAT SIDE TABLE (w/ Table)

Remove the 4 nuts and seat side table.

Rem ...

How to proceed with

troubleshooting

HINT:

Troubleshoot in accordance with the procedures on the

following pages

1 VEHICLE BROUGHT TO WORKSHOP

2 CUSTOMER PROBLEM ANALYSIS CHECK AND SYMPTOM CHECK

3 INSPECT COMMUNICATION FUNCTION OF LARGE-SCALE MULTIPLEX

COMMUNICATION SYSTEM (BEAN)

Use the intelligent tester to check for normal ...

Installation

1. Install generator assembly

(a) Install the bracket with the bolt.

Torque: 20 N*m (204 kgf*cm, 15 ft.*lbf)

(b) Install the wire harness clamp stay.

Torque: 8.4 N*m (86 kgf*cm, 74 in.*lbf)

(c) Connect the wire harness clamp.

(d) Install the generator assembly to the cylinder ...