Toyota Sienna Service Manual: Automatic transaxle fluid

On-vehicle inspection

1. CHECK FLUID LEVEL

HINT: Drive the vehicle so that the engine and transaxle are at normal operating temperature.

Fluid temperature: 70 to 80°C (158 to 176°F)

(a) Park the vehicle on a level surface and set the parking brake.

(b) With the engine idling and the brake pedal depressed, move the shift lever to all positions from P to L and return to the P position.

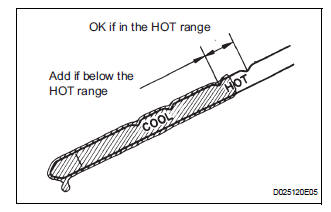

(c) Take out the dipstick and wipe it clean.

(d) Put the dipstick back all the way.

(e) Take out the dipstick again and check that the fluid level is within the HOT range.

If the fluid level is below the HOT range, add new fluid and recheck the fluid level.

If the fluid level exceeds the HOT range, drain the fluid once, add the proper amount of new fluid and recheck the fluid level.

If there are leaks, it is necessary to repair or replace O-rings, FIPGs, oil seals, plugs and/or other parts.

Park / neutral position switch

Park / neutral position switch

Components

...

Other materials:

On-vehicle inspection

1. CONNECT INTELLIGENT TESTER

(a) Connect the intelligent tester to the DLC3.

(b) Start the engine and run at idle.

(c) Select the ACTIVE TEST mode on the intelligent

tester.

HINT:

Please refer to the intelligent tester operator's

manual for further details.

2. INSPECT ACTUATOR MOTOR ...

Transmitter ID not Registered

DTC C2171/71 Transmitter ID not Registered

DESCRIPTION

The IDs of each tire pressure warning valve and transmitters are registered

to the tire pressure warning

ECU.

When the IDs have never been registered, a DTC is output.

INSPECTION PROCEDURE

NOTICE:

When replacing the tire pressu ...

Installation

1. INSTALL FOG LIGHT ASSEMBLY

Install the fog light assembly with the 2 claws and 2

pins.

2. INSTALL FRONT BUMPER ASSEMBLY

3. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

4. VEHICLE PREPARATION FOR FOG LIGHT AIMING

5. PREPARATION FOR FOG LIGHT AIMING

6. FOG LIGHT AIMING INSPECT ...