Toyota Sienna Service Manual: Blower Motor Circuit

DESCRIPTION

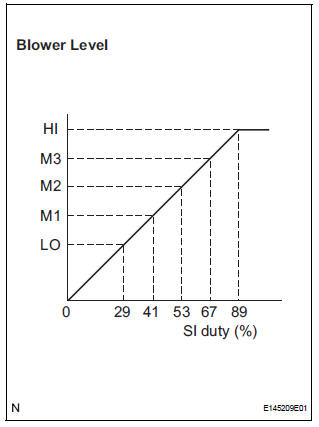

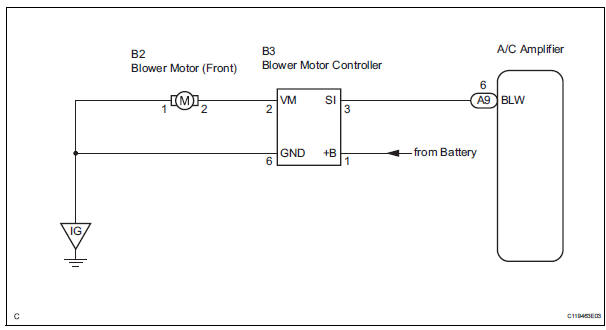

The blower motor is operated by signals from the A/C amplifier. Blower motor speed signals are transmitted by changes in the Duty Ratio.

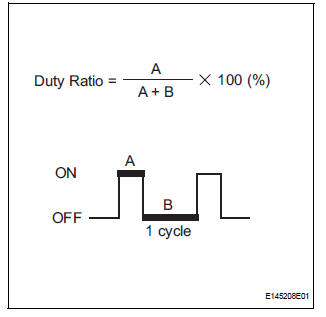

Duty Ratio

The duty ratio is the ratio of the period of continuity in one cycle. For example, if A is the period of continuity in one cycle, and B is the period of non-continuity, then Duty Ratio = A/(A+B) x 100 (%).

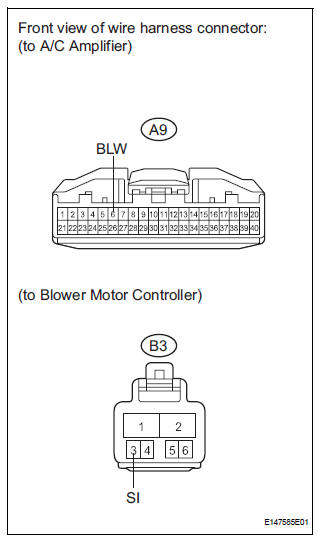

WIRING DIAGRAM

INSPECTION PROCEDURE

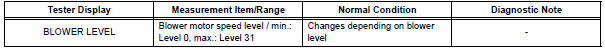

1 READ VALUE OF INTELLIGENT TESTER

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the intelligent tester main switch on.

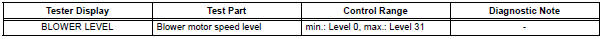

(c) Select the item below in the DATA LIST, and read the display on the intelligent tester.

DATA LIST / AIR CONDITIONER

OK: The display is as specified in the normal condition column.

PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS TABLE

2 PERFORM ACTIVE TEST BY INTELLIGENT TESTER

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the intelligent tester main switch on.

(c) Select the item below in the ACTIVE TEST and then check that the blower motor operates.

ACTIVE TEST / AIR CONDITIONER

OK: The blower motor operates and the blower level changes.

PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS TABLE

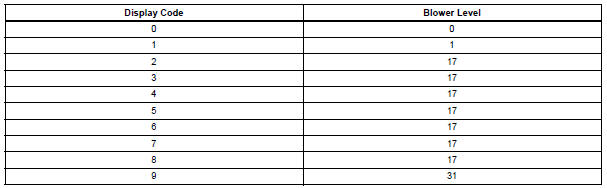

3 PERFORM ACTUATOR CHECK

(a) Enter the actuator check mode (See page AC-15).

(b) Press the DEF switch to change to the step operation.

(c) Check the air flow level by hand.

OK: The blower level changes in accordance with each display code.

PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS TABLE

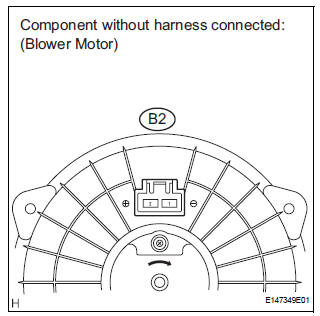

4 INSPECT BLOWER MOTOR

(a) Remove the blower motor.

(b) Disconnect the connector from the blower motor.

(c) Connect the positive (+) lead from the battery to terminal 2 and the negative (-) lead to terminal 1, and check that the motor operates.

OK: Blower motor operates smoothly.

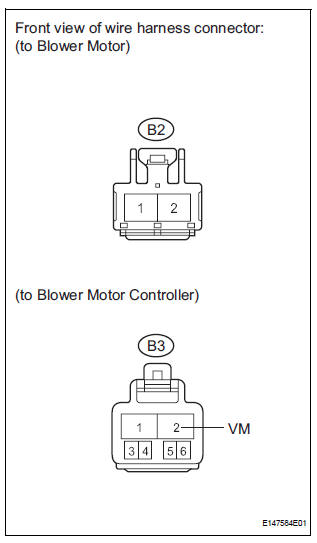

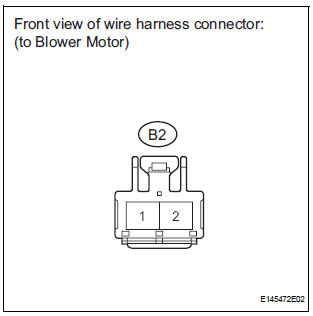

5 CHECK HARNESS AND CONNECTOR (BLOWER MOTOR - BLOWER MOTOR CONTROLLER)

(a) Disconnect the connector from the blower motor.

(b) Disconnect the connector from the blower motor controller.

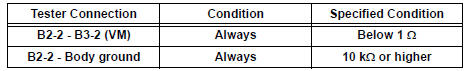

(c) Measure the resistance according to the value(s) in the table below.

Standard resistance

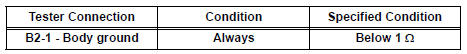

6 CHECK HARNESS AND CONNECTOR (BLOWER MOTOR - BODY GROUND)

(a) Measure the resistance according to the value(s) in the table below.

Standard resistance

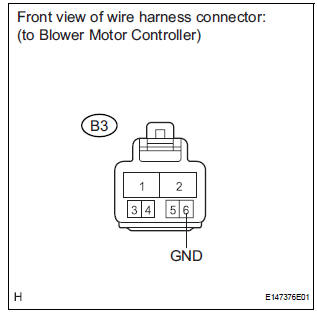

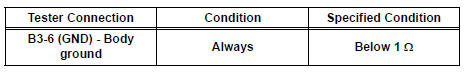

7 CHECK HARNESS AND CONNECTOR (BLOWER MOTOR CONTROLLER - BODY GROUND)

(a) Measure the resistance according to the value(s) in the table below.

Standard resistance

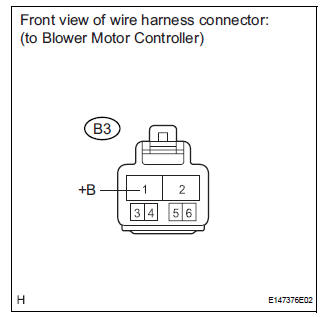

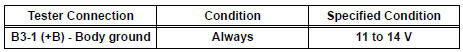

8 CHECK HARNESS AND CONNECTOR (BLOWER MOTOR CONTROLLER - BATTERY)

(a) Measure the voltage according to the value(s) in the table below.

Standard voltage

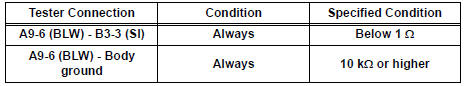

9 CHECK HARNESS AND CONNECTOR (A/C AMPLIFIER - BLOWER MOTOR CONTROLLER)

(a) Disconnect the connector from the A/C amplifier.

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

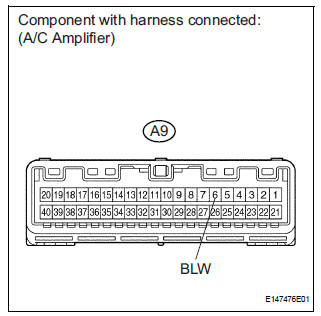

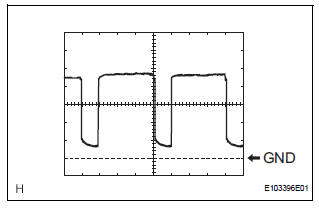

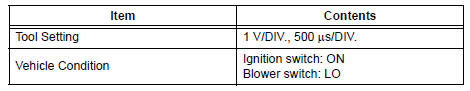

10 INSPECT A/C AMPLIFIER

(a) Reconnect the connector to the A/C amplifier.

(b) Reconnect the connector to the blower motor controller.

(c) Reconnect the connector to the blower motor

(d) Measure the waveform between terminal A9-6 (BLW) of the A/C amplifier and body ground.

OK: Waveform is as shown in the illustration.

HINT:

Waveform varies with the blower level.

REPLACE BLOWER MOTOR CONTROLLER

Multiplex Communication Circuit

Multiplex Communication Circuit

DESCRIPTION

INSPECTION PROCEDURE

1 GO TO CAN COMMUNICATION SYSTEM

(a) Refer to the CAN communication system (See page CA-

7).

(b) If the CAN communication system is operating normally,

procee ...

Air Conditioning Compressor Magnetic Clutch Circuit

Air Conditioning Compressor Magnetic Clutch Circuit

DESCRIPTION

When the A/C amplifier is turned on, a magnetic clutch ON signal is sent from

the MGC terminal of the A/

C amplifier. Then, the MG CLT relay turns on to operate the magnetic clutch.

W ...

Other materials:

Installation

1. INSTALL STEERING COLUMN ASSEMBLY

(a) Install the steering column assembly with the 3

bolts.

Torque: 25 N*m (255 kgf*cm, 18 ft.*lbf)

(b) Connect the connectors.

(c) Connect the wire harness clamps to the steering

column tube.

2. CONNECT STEERING INTERMEDIATE SHAFT ASSEMBLY

(a) ...

Manual Up / Down and Auto Down Function does not Operate on

Passenger Side Only

DESCRIPTION

If the manual UP/DOWN function does not operate, the power window motor, the

regulator switch or the

wire harness may be malfunctioning.

WIRING DIAGRAM

INSPECTION PROCEDURE

1 CHECK WIRE HARNESS (POWER SOURCE)

Disconnect the P37 regulator switch connector.

Turn ...

Bluetooth Module Initialization Failed

DTC 57-47 Bluetooth Module Initialization Failed

DESCRIPTION

DTC No.

DTC Detection Condition

Trouble Area

57-47

Bluetooth module is not installed.

Problem with Bluetooth module

Problem in communication line to Bluetooth module

...