Toyota Sienna Service Manual: Brake Switch "B" Circuit High

DESCRIPTION

The purpose of this circuit is to prevent the engine from stalling while driving in lock-up condition when brakes are suddenly applied.

When the brake pedal is depressed, this switch sends a signals to the ECM. Then the ECM cancels the operation of the lock-up clutch while braking is in progress.

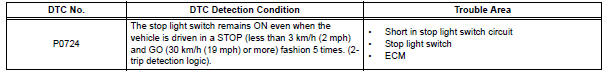

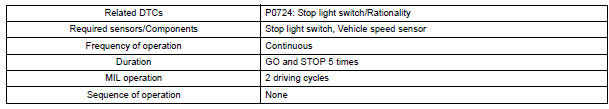

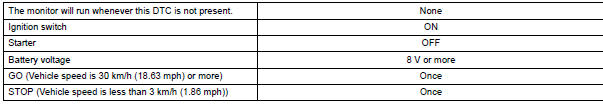

MONITOR DESCRIPTION

This DTC indicates that the stop light switch remains on. When the stop light switch remains ON during "stop and go" driving, the ECM interprets this as a fault in the stop light switch and the MIL comes on and the ECM stores the DTC. The vehicle must stop (less than 3 km/h (2 mph)) and go (30 km/h (19 mph) or more) 5 times for two driving cycles in order to detect a malfunction.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

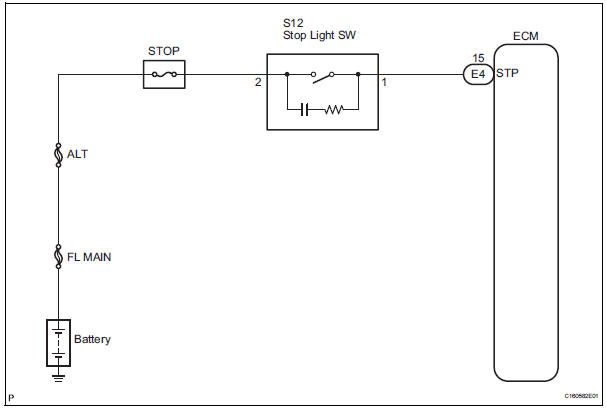

WIRING DIAGRAM

INSPECTION PROCEDURE

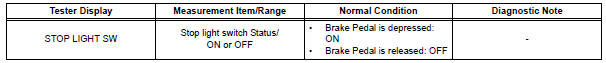

1 READ VALUE OF DATA LIST

HINT: Using the intelligent tester to read the DATA LIST allows the values or states of switches, sensors, actuators and other items to be read without removing any parts. This nonintrusive inspection can be very useful because intermittent conditions or signals may be discovered before parts or wiring is disturbed. Reading the DATA LIST information early in troubleshooting is one way to save diagnostic time.

(a) Warm up the engine.

(b) Turn the ignition switch off.

(c) Connect the OBD II scan tool or intelligent tester together with the CAN VIM (controller area network vehicle interface module) to the DLC3.

(d) Turn the ignition switch to the ON position.

(e) Turn on the tester.

(f) Select the item "DIAGNOSIS / ENHANCED OBD II / DATA LIST".

(g) According to the display on the tester, read the "DATA

LIST".

| NOTICE: In the table below, the value listed under "Normal Condition" are reference values. Do not depend solely on these reference values when deciding whether apart is faulty or not. |

Result

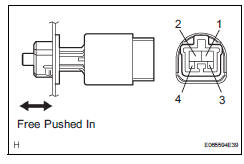

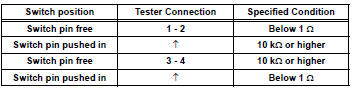

2 INSPECT STOP LIGHT SWITCH ASSEMBLY

(a) Remove the stop light switch assembly.

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

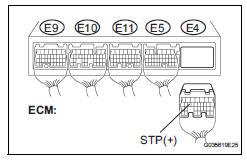

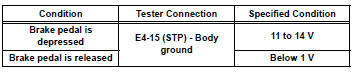

3 CHECK HARNESS AND CONNECTOR (STOP LIGHT SWITCH ASSEMBLY - ECM)

(a) Install the stop light switch assembly.

(b) Measure the voltage according to the value(s) in the table below when the brake pedal is depressed and released.

Standard voltage

REPLACE ECM

Turbine Speed Sensor Circuit No Signal

Turbine Speed Sensor Circuit No Signal

DESCRIPTION

This sensor detects the rotation speed of the input turbine. By comparing the

input turbine speed signal

(NT) with the counter gear speed sensor signal (NC), the ECM detects the sh ...

Torque Converter Clutch Solenoid Performance

(Shift Solenoid Valve DSL)

Torque Converter Clutch Solenoid Performance

(Shift Solenoid Valve DSL)

SYSTEM DESCRIPTION

The ECM uses the signals from the throttle position sensor, air-flow meter,

turbine (input) speed sensor,

intermediate (counter) shaft speed sensor and crankshaft position s ...

Other materials:

Tire size

Typical tire size information

The illustration indicates typical tire size.

Tire use

(P = Passenger car,

T = Temporary use)

Section width (millimeters)

Aspect ratio

(tire height to section width)

Tire construction code

(R = Radial, D = Diagonal)

Wheel diameter (inches)

...

A/C ECU Communication Stop

DTC B1262 A/C ECU Communication Stop

DESCRIPTION

DTC B1262 is output when communication between the A/C amplifier and the

multiplex network gateway

ECU stops for more than 10 seconds.

DTC No.

DTC Detection Condition

Trouble Area

B1262

A/C ECU communicat ...

Short in CAN Bus Lines

DESCRIPTION

The CAN bus wires are considered to be shorted when the resistance between

terminals 6 (CANH) and

14 (CANL) of the DLC3 is below 54 Ω.

Symptom

Trouble Area

Resistance between terminals 6 (CANH) and 14 (CANL) of the DLC3

is below 54 Ω.

...