Toyota Sienna Service Manual: Camshaft Position "A" Actuator Circuit

DTC P0010 Camshaft Position "A" Actuator Circuit (Bank 1)

DTC P0020 Camshaft Position "A" Actuator Circuit (Bank 2)

DESCRIPTION

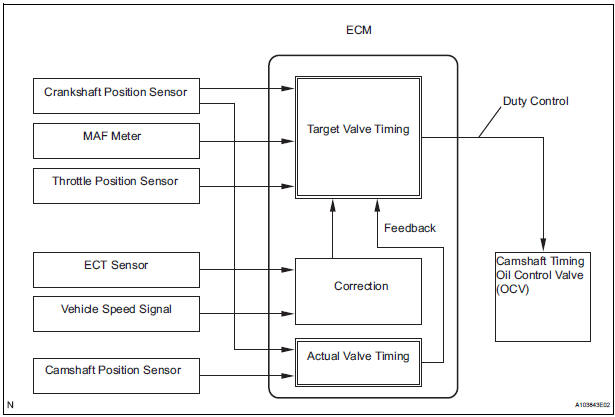

The Variable Valve Timing (VVT) system includes the ECM, Oil Control Valve (OCV) and VVT controller.

The ECM sends a target duty-cycle control signal to the OCV. This control signal regulates the oil pressure supplied to the VVT controller. Camshaft timing control is performed according to engine operating conditions such as intake air volume, throttle valve position and engine coolant temperature.

The ECM controls the OCV, based on the signals transmitted by several sensors. The VVT controller regulates the intake camshaft angle using oil pressure through the OCV. As a result, the relative positions of the camshaft and crankshaft are optimized, the engine torque and fuel economy improves, and the exhaust emissions decrease under overall driving conditions. The ECM detects the actual intake valve timing using signals from the camshaft and crankshaft position sensors, and performs feedback control.

This is how the target intake valve timing is verified by the ECM.

|

DTC No. |

DTC Detection Condition |

Trouble Area |

| P0010 | Open or short in OCV for intake camshaft (bank 1) circuit (1 trip detection logic) |

|

| P0020 | Open or short in OCV for intake camshaft (bank 2) circuit (1 trip detection logic) |

|

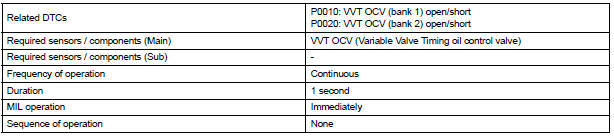

MONITOR DESCRIPTION

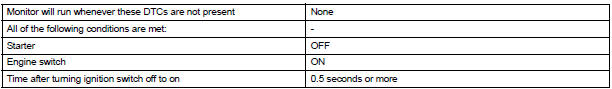

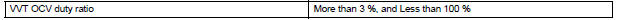

After the ECM sends the "target" duty-cycle signal to the OCV, the ECM monitors the OCV current to establish an "actual" duty-cycle. The ECM detects a malfunction and sets a DTC when the actual dutycycle ratio varies from the target duty-cycle ratio.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

COMPONENT OPERATING RANGE

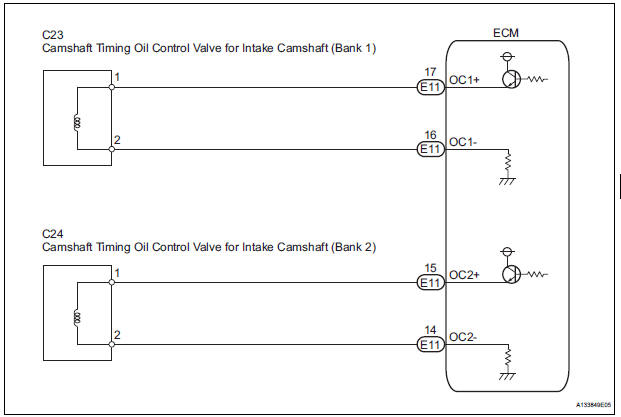

WIRING DIAGRAM

INSPECTION PROCEDURE

HINT:

- If DTC P0010 is displayed, check the intake camshaft circuit for the right bank VVT system.

- Bank 1 refers to the bank that includes cylinder No. 1.

- If DTC P0020 is displayed, check the intake camshaft circuit for the left bank VVT system.

- Bank 2 refers to the bank that does not include cylinder No. 1.

- Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can be helpful in determining whether the vehicle was running or stopped, whether the engine was warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the time of a malfunction.

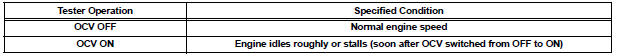

1 PERFORM ACTIVE TEST BY CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY (OCV)

- Connect the intelligent tester to the DLC3.

- Start the engine and turn the tester on.

- Warm up the engine.

- On the tester, enter the following menus: DIAGNOSIS / ENHANCED OBD II / ACTIVE TEST / VVT CTRL B1 or VVT CTRL B2.

- Check the engine speed while operating the Oil Control Valve (OCV) using the tester

OK

2 INSPECT CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY

- Disconnect the C23 or C24 camshaft timing oil control valve (OCV) connector.

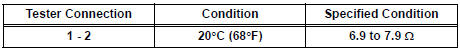

- Measure the resistance according to the value(s) in the table below.

Standard resistance

- Reconnect the OCV connector

3 CHECK HARNESS AND CONNECTOR (OCV - ECM)

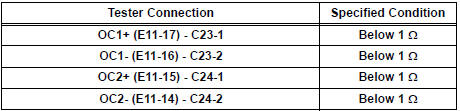

- Disconnect the C23 or C24 camshaft timing oil control valve (OCV) connector.

- Disconnect the E11 ECM connector.

- Measure the resistance according to the value(s) in the table below.

Standard resistance (Check for open)

Standard resistance (Check for short)

- Reconnect the OCV connector.

- Reconnect the ECM connector.

REPLACE ECM

Diagnostic trouble code chart

Diagnostic trouble code chart

HINT:

The parameters listed in the chart may not confirm exactly to

those read during the DTC check due to the type of

instrument or other factors.

If a trouble code is displayed during the DTC ...

Camshaft Position "A" - Timing Over-Advanced

Camshaft Position "A" - Timing Over-Advanced

DTC P0011 Camshaft Position "A" - Timing Over-Advanced

or System Performance (Bank 1)

DTC P0012 Camshaft Position "A" - Timing Over-Retarded

(Bank 1)

DTC P0021 Camshaft Positio ...

Other materials:

System description

1. CRUISE CONTROL SYSTEM

This system is controlled by the ECM, and is activated by

the throttle position sensor and motor. The ECM controls

the following functions: ON-OFF, - (COAST)/SET, +

(ACCEL)/RES (RESUME), CANCEL, vehicle speed

operation, motor output control, and overdrive control.

& ...

Unlocking and locking the doors from the outside

Entry function (vehicles with a smart key system)

Carry the electronic key to enable this function.

Grip the driver’s door handle

to unlock the door. Grip the

passenger’s door handle to

unlock all the doors.*

Make sure to touch the sensor

on the back of the handle.

The doors ...

For rear air conditioning system

ON-VEHICLE INSPECTION

1. INSPECT REAR AIR MIX CONTROL SERVO MOTOR

(a) Inspect servo motor operation.

(1) Connect the positive (+) lead from the battery

to terminal 4 and negative (-) lead to terminal 5,

then check that the arm turns to "HOT" side

smoothly.

(2) Connect the po ...