Toyota Sienna Service Manual: Center Airbag Sensor Assembly Malfunction

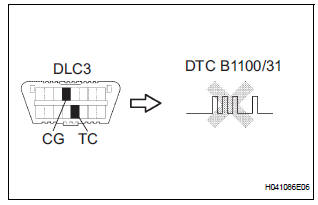

DTC B1100/31 Center Airbag Sensor Assembly Malfunction

DESCRIPTION

The center airbag sensor assembly consists of the center airbag sensor assembly, safing sensor, drive circuit, diagnosis circuit and ignition control, etc.

It receives signals from the airbag sensor, judges whether or not the SRS must be activated, and detects diagnosis system malfunction.

DTC B1100/31 is recorded when a malfunction is detected in the center airbag sensor assembly circuit.

|

DTC No. |

DTC Detecting Condition |

Trouble Area |

|

B1100/31 |

|

|

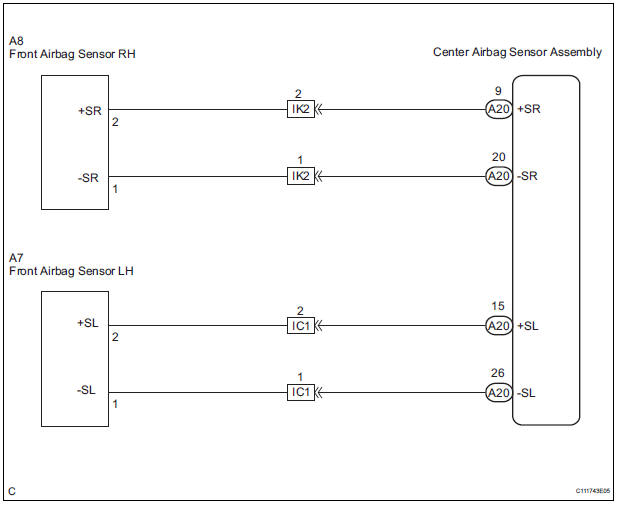

WIRING DIAGRAM

INSPECTION PROCEDURE

HINT: When a trouble code is displayed simultaneously with B1100/31, repair the malfunction indicated by this code (except B1100/31) first.

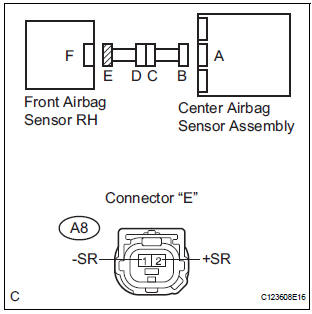

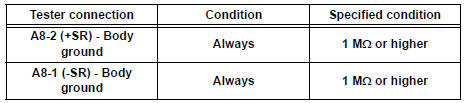

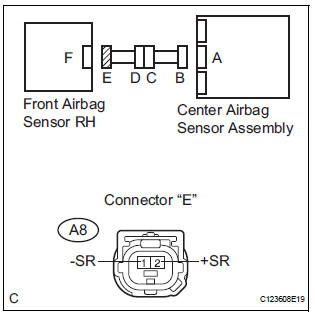

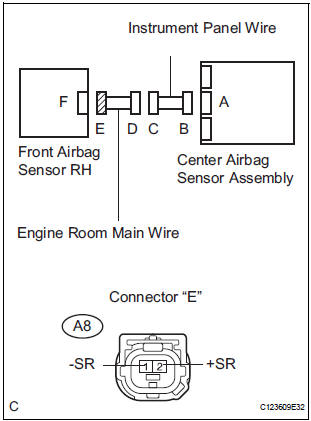

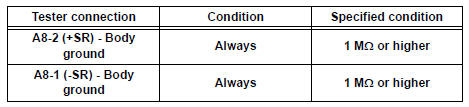

1 CHECK FRONT AIRBAG SENSOR RH CIRCUIT (SHORT TO GROUND)

- Turn the ignition switch to the LOCK position.

- Disconnect the negative (-) terminal cable from the battery, and wait for at least 90 seconds.

- Disconnect the connectors from the front airbag sensor RH and the center airbag sensor assembly.

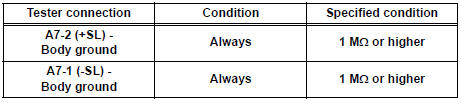

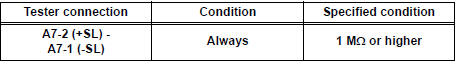

- Measure the resistance according to the value(s) in the table below.

Standard resistance

Go to step 8

Go to step 8

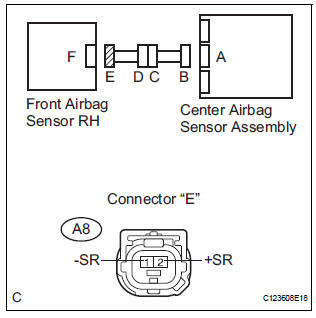

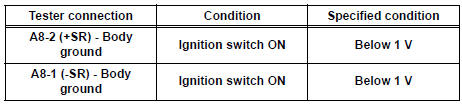

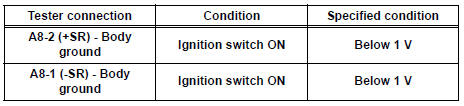

2 CHECK FRONT AIRBAG SENSOR RH CIRCUIT (SHORT TO B+)

- Connect the negative (-) terminal cable to the battery, and wait for at least 2 seconds.

- Turn the ignition switch to the ON position.

- Measure the voltage according to the value(s) in the table below.

Standard voltage

Go to step 9

Go to step 9

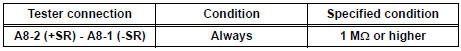

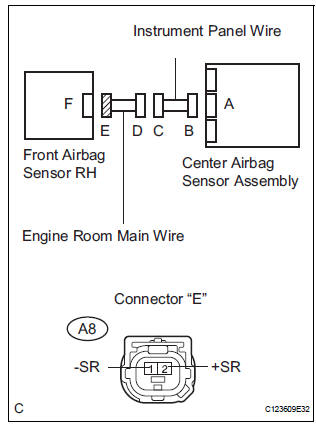

3 CHECK FRONT AIRBAG SENSOR RH CIRCUIT (SHORT)

- Turn the ignition switch to the LOCK position.

- Disconnect the negative (-) terminal cable from the battery, and wait for at least 90 seconds.

- Measure the resistance according to the value(s) in the table below.

Standard resistance

Go to step 10

Go to step 10

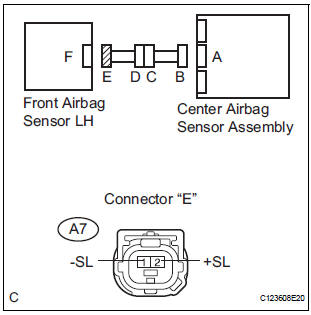

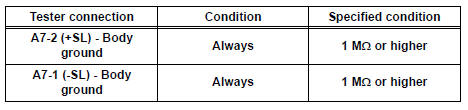

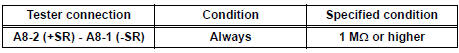

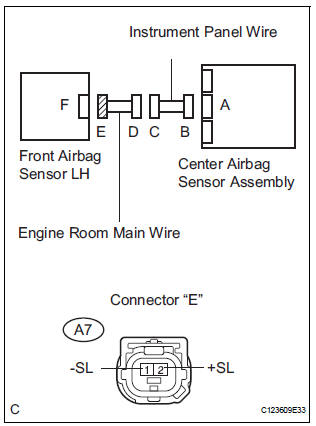

4 CHECK FRONT AIRBAG SENSOR LH CIRCUIT (SHORT TO GROUND)

- Disconnect the connector from the front airbag sensor LH.

- Measure the resistance according to the value(s) in the table below.

Standard resistance

Go to step 11

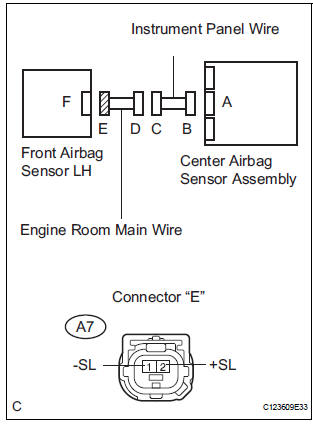

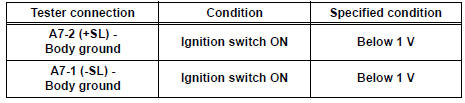

5 CHECK FRONT AIRBAG SENSOR LH CIRCUIT (SHORT TO B+)

- Connect the negative (-) terminal cable to the battery, and wait for at least 2 seconds.

- Turn the ignition switch to the ON position.

- Measure the voltage according to the value(s) in the table below.

Standard voltage

Go to step 12

Go to step 12

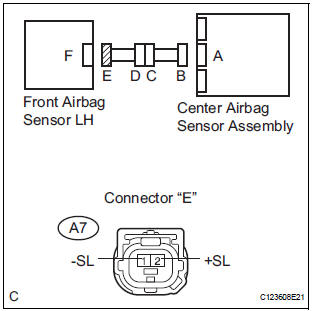

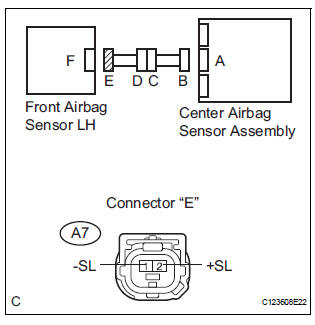

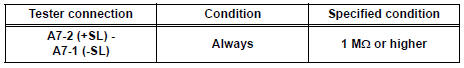

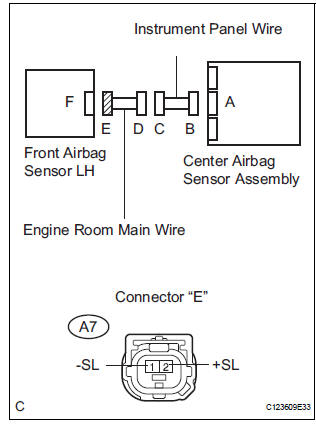

6 CHECK FRONT AIRBAG SENSOR LH CIRCUIT (SHORT)

- Turn the ignition switch to the LOCK position.

- Disconnect the negative (-) terminal cable from the battery, and wait for at least 90 seconds.

- Measure the resistance according to the value(s) in the table below.

Standard resistance

Go to step 13

Go to step 13

7 CHECK CENTER AIRBAG SENSOR ASSEMBLY

- Connect the connectors to the center airbag sensor assembly, front airbag sensors RH and LH.

- Connect the negative (-) terminal cable to the battery, and wait for at least 2 seconds.

- Turn the ignition switch to the ON position, and wait for at least 60 seconds.

- Clear the DTCs stored in memory (5).

- Turn the ignition switch to the LOCK position.

- Turn the ignition switch to the ON position, and wait for at least 60 seconds.

- Check the DTCs (5).

OK: DTC B1100/31 is not output.

REPLACE CENTER AIRBAG SENSOR

ASSEMBLY

REPLACE CENTER AIRBAG SENSOR

ASSEMBLY

USE SIMULATION METHOD TO CHECK

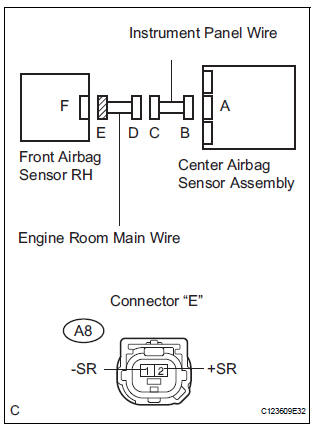

8 CHECK ENGINE ROOM MAIN WIRE (SHORT TO GROUND)

- Disconnect the engine room main wire connector from the instrument panel wire.

- Measure the resistance according to the value(s) in the table below.

Standard resistance

REPAIR OR REPLACE ENGINE ROOM

MAIN

WIRE

REPAIR OR REPLACE ENGINE ROOM

MAIN

WIRE

REPAIR OR REPLACE INSTRUMENT PANEL WIRE

9 CHECK ENGINE ROOM MAIN WIRE (SHORT TO B+)

- Turn the ignition switch to the LOCK position.

- Disconnect the negative (-) terminal cable from the battery, and wait for at least 90 seconds.

- Disconnect the engine room main wire connector from the instrument panel wire.

- Connect the negative (-) terminal cable to the battery, and wait for at least 2 seconds.

- Turn the ignition switch to the ON position.

- Measure the voltage according to the value(s) in the table below.

Standard voltage

REPAIR OR REPLACE ENGINE

ROOM MAIN

WIRE

REPAIR OR REPLACE ENGINE

ROOM MAIN

WIRE

REPAIR OR REPLACE INSTRUMENT PANEL WIRE

10 CHECK ENGINE ROOM MAIN WIRE (SHORT)

- Disconnect the engine room main wire connector from the instrument panel wire.

- Measure the resistance according to the value(s) in the table below.

Standard resistance

REPAIR OR REPLACE ENGINE ROOM

MAIN

WIRE

REPAIR OR REPLACE ENGINE ROOM

MAIN

WIRE

REPAIR OR REPLACE INSTRUMENT PANEL WIRE

11 CHECK ENGINE ROOM MAIN WIRE (SHORT TO GROUND)

- Disconnect the engine room main wire connector from the instrument panel wire.

- Measure the resistance according to the value(s) in the table below.

Standard resistance

REPAIR OR REPLACE ENGINE ROOM

MAIN

WIRE

REPAIR OR REPLACE ENGINE ROOM

MAIN

WIRE

REPAIR OR REPLACE INSTRUMENT PANEL WIRE

12 CHECK ENGINE ROOM MAIN WIRE (SHORT TO B+)

- Turn the ignition switch to the LOCK position.

- Disconnect the negative (-) terminal cable from the battery, and wait for at least 90 seconds.

- Disconnect the engine room main wire connector from the instrument panel wire.

- Connect the negative (-) terminal cable to the battery, and wait for at least 2 seconds.

- Turn the ignition switch to the ON position.

- Measure the voltage according to the value(s) in the table below.

Standard voltage

REPAIR OR REPLACE ENGINE ROOM

MAIN

WIRE

REPAIR OR REPLACE ENGINE ROOM

MAIN

WIRE

REPAIR OR REPLACE INSTRUMENT PANEL WIRE

13 CHECK ENGINE ROOM MAIN WIRE (SHORT)

- Disconnect the engine room main wire connector from the instrument panel wire.

- Measure the resistance according to the value(s) in the table below.

Standard resistance

REPAIR OR REPLACE ENGINE

ROOM MAIN

WIRE

REPAIR OR REPLACE ENGINE

ROOM MAIN

WIRE

REPAIR OR REPLACE INSTRUMENT PANEL WIRE

Short to B+ in Front Pretensioner Squib LH Circuit

Short to B+ in Front Pretensioner Squib LH Circuit

DTC B0138/72 Short to B+ in Front Pretensioner Squib LH Circuit

DESCRIPTION

The front pretensioner squib LH circuit consists of the center airbag sensor

assembly and the front seat

outer belt ass ...

Half Connection in Center Airbag Sensor

Assembly Connectors

Half Connection in Center Airbag Sensor

Assembly Connectors

DTC B1135/24 Half Connection in Center Airbag Sensor

Assembly Connectors

DESCRIPTION

The center airbag sensor assembly connector has a mechanism that electrically

detects half connection.

The ...

Other materials:

Disassembly

1. INSPECT UNDERDRIVE PACK CLEARANCE

HINT:

(See page AX-262)

2. REMOVE UNDERDRIVE CLUTCH FLANGE NO.2 HOLE

SNAP RING

a) Using a screwdriver, remove the underdrive clutch

flange No.2 snap ring.

3. REMOVE UNDERDRIVE CLUTCH DISC NO.1

(a) Remove the flange, 4 discs and 4 plates from the

...

Repair

1. REPAIR REAR WINDOW DEFOGGER WIRE

Clean the broken wire tips with grease, wax and

silicone remover.

Place the masking tape along the both sides of the

wire.

Thoroughly mix the repair agent (Dupont paste No.

4817).

Using a fine tip brush, apply a smal ...

Open in Side Squib RH Circuit

DTC B0111/44 Open in Side Squib RH Circuit

DESCRIPTION

The side squib RH circuit consists of the center airbag sensor assembly and

the front seat side airbag

assembly RH.

The circuit instructs the SRS to deploy when deployment conditions are met.

DTC B0111/44 is recorded when an open circ ...