Toyota Sienna Service Manual: Definition of terms

|

Terms |

Definitions |

| Monitor Description | Description of what ECM monitors and how to detect malfunctions (monitoring purpose and details). |

| Related DTCs | A group of diagnostic trouble codes that are output by ECM based on the same malfunction detection logic. |

| Typical Enabling Conditions | Preconditions that allow ECM to detect malfunction.

With all preconditions satisfied, ECM sets DTC when monitored value(s) exceeds malfunction threshold(s). |

| Sequence of Operation | Order of monitor priority, applied if multiple sensors and

components are involved in single malfunction detection

process.

Each sensor and component monitored in turn and not monitored until previous detection operation is completed. |

| Required Sensors / Components | Sensors and components used by ECM to detect each malfunction. |

| Frequency of Operation | Number of times ECM checks for each malfunction during each driving

cycle.

"Once per driving cycle" means ECM performs checks for that malfunction only once in single driving cycle. "Continuous" means ECM performs checks for that malfunction whenever enabling conditions are met. |

| Duration | Minimum time for which ECM must detect continuous deviation in monitored value(s) in order to set DTC. Timing begins when typical enabling conditions are met. |

| Malfunction Thresholds | Values, beyond which, ECM determines malfunctions exist and sets DTCs. |

| MIL Operation | Timing of MIL illumination after defect is detected.

"Immediate" means ECM illuminates MIL as soon as malfunction is detected. "2 driving cycles" means ECM illuminates MIL if the same malfunction is detected twice during the next sequential driving cycle. |

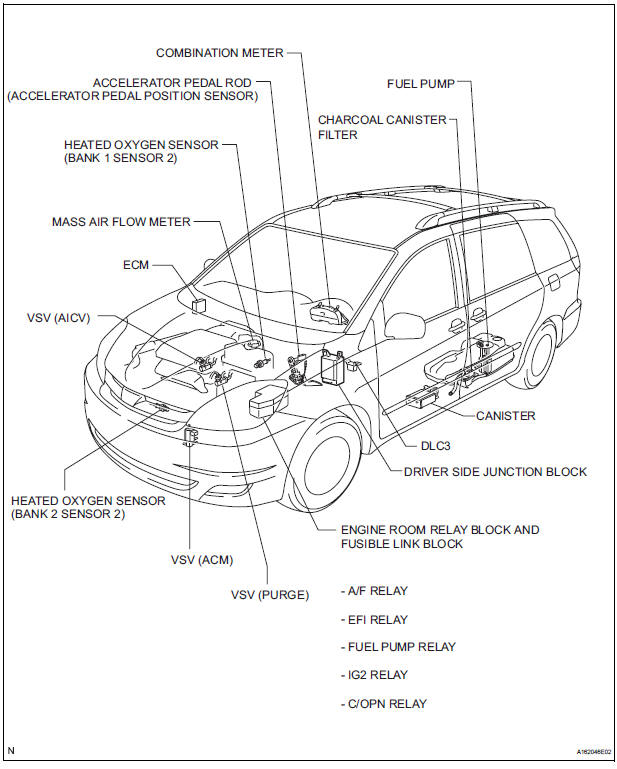

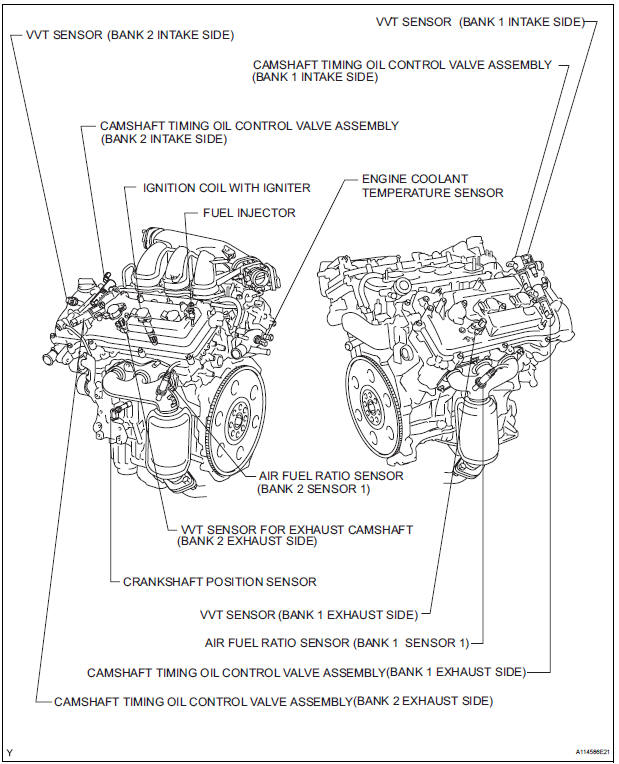

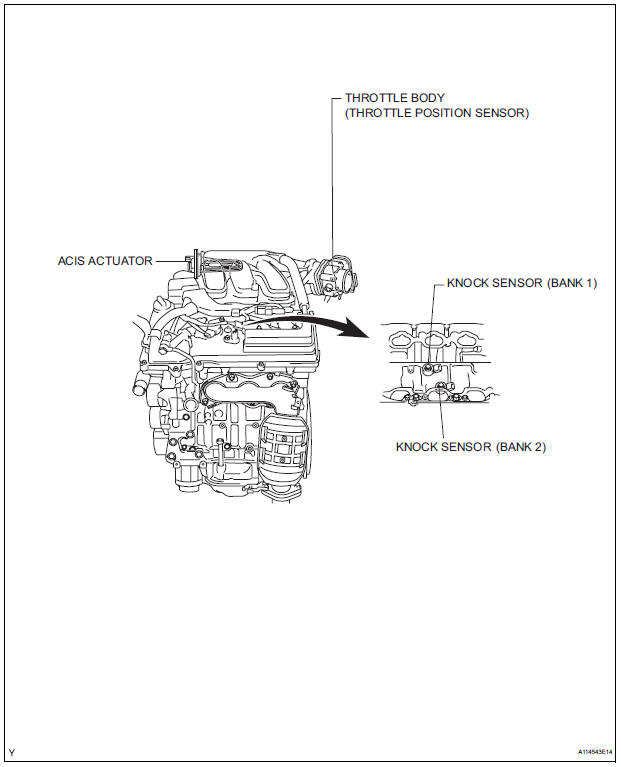

PARTS LOCATION

Precaution

Precaution

1. INITIALIZATION

NOTICE:

Perform RESET MEMORY (AT initialization) when

replacing the automatic transaxle assembly, engine

assembly or ECM (See page AX-16).

Perform REGISTRATIO ...

System diagram

System diagram

...

Other materials:

Input instructions

(a) The general VIN input instructions using the

intelligent tester are shown below:

(b) The arrow buttons (UP, DOWN, RIGHT and LEFT)

and numerical buttons (0 to 9) are used to input the

VIN.

(c) Cursor Operation

To move the cursor around the tester screen, press

the RIGHT and LEFT buttons. ...

Rear Occupant Classification Sensor RH Collision

Detection

DTC B1788 Rear Occupant Classification Sensor RH Collision

Detection

DESCRIPTION

DTC B1788 is output when the occupant classification ECU receives a collision

detection signal sent by

the rear occupant classification sensor RH if an accident occurs.

DTC B1788 is also output when the front s ...

Memory Switch Circuit

DESCRIPTION

When the seat memory switch M1 or M2 is pressed, the position control ECU &

switch (Seat ECU)

transmits a signal of the memorized mirror position to the outer mirror control

ECU. Then, the outer mirror

control ECU drives the mirror motor.

HINT:

The power mirror control syste ...