Toyota Sienna Service Manual: Definition of terms

| Term | Definition |

| Monitor description | Description of what the ecm monitors and how it detects malfunctions (monitoring purpose and its details). |

| Related dtcs | Diagnostic codeV |

| Typical enabling condition | Preconditions that allow the ecm to detect malfunctions.

With all preconditions satisfied, the ecm sets the dtc when the monitored value(s) exceeds the malfunction threshold(s). |

| Sequence of operation | The priority order that is applied to monitoring, if multiple

sensors and components are used to detect the

malfunction.

While another sensor is being monitored, the next sensor or component will not be monitored until the previous monitoring has concluded. |

| Required sensor/components | The sensors and components that are used by the ecm to detect malfunctions. |

| Frequency of operation | The number of times that the ecm checks for malfunctions

per driving cycle.

"Once per driving cycle" means that the ecm detects malfunction only one time during a single driving cycle. "Continuous" means that the ecm detects malfunction every time when enabling condition is met. |

| Duration | The minimum time that the ecm must sense a continuous deviation in the monitored value(s) before setting a dtc. This timing begins after the "typical enabling conditions" are met. |

| Malfunction thresholds | Beyond this value, the ecm will conclude that there is a malfunction and set a dtc. |

| MIL operation | Mil illumination timing after a defect is detected.

"Immediately" means that the ecm illuminates mil the instant the ecm determines that there is a malfunction. "2 Driving cycle" means that the ecm illuminates mil if the same malfunction is detected again in the 2nd driving cycle. |

| Component operating range | Normal operation range of sensors and solenoids under normal driving

conditions.

Use these ranges as a reference. They cannot be used to judge if a sensor or solenoid is defective or not.V |

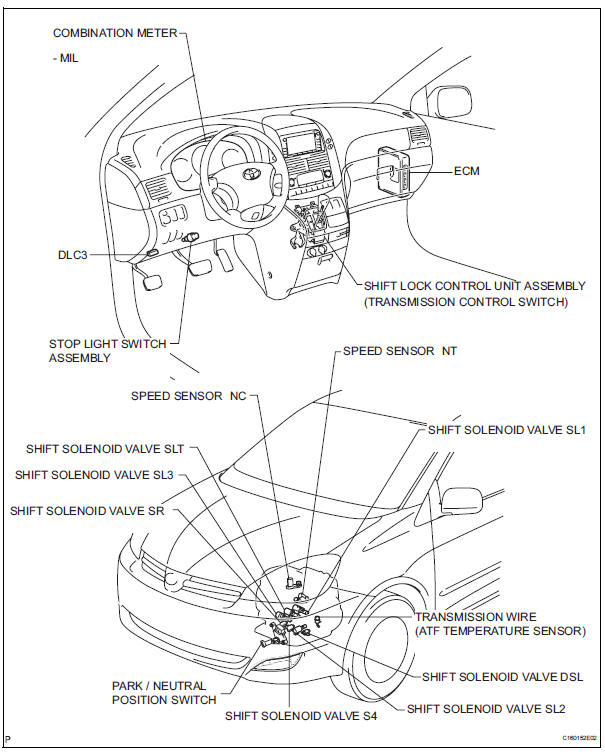

Parts location

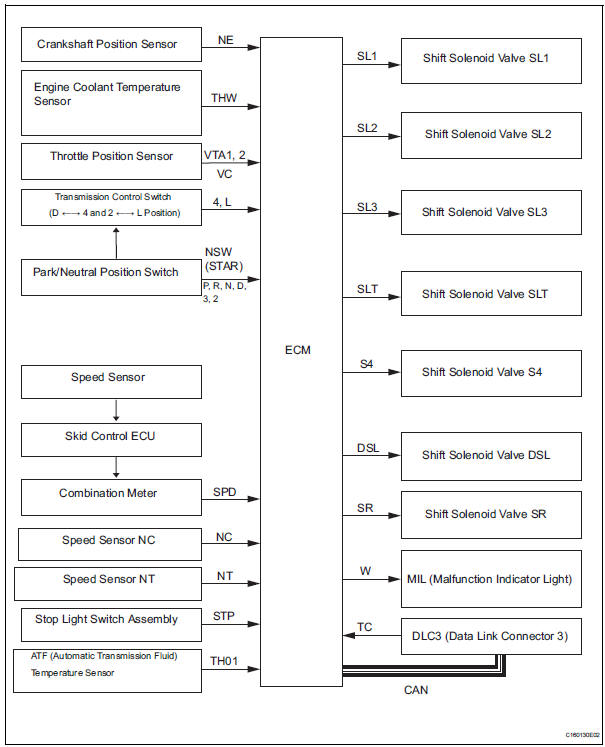

System diagram

The configuration of the electronic control system in the U151E automatic transaxles is as shown in the following chart.

Precaution

Precaution

NOTICE:

Perform the RESET MEMORY (AT initialization) when

replacing the automatic transaxle assembly, engine

assembly or ECM (See page AX-16).

Perform the REGISTRATION (VIN regi ...

System description

System description

1. SYSTEM DESCRIPTION

(a) The ECT (Electronic controlled automatic

transmission/transaxle) is an automatic

transmission/transaxle that electronically controls

shift timing using the ECM. The ECM d ...

Other materials:

Evaporator temperature sensor (for rear air conditioning system)

ON-VEHICLE INSPECTION

1. INSPECT REAR A/C EVAPORATOR TEMPERATURE SENSOR

(a) Remove the rear evaporator temperature sensor.

(b) Disconnect the connector from the rear evaporator

temperature sensor.

(c) Measure the resistance according to the value(s) in

the table below.

Standard re ...

Removal

1. REMOVE ENGINE ASSEMBLY WITH TRANSAXLE

HINT:

(See page EM-26)

2. REMOVE FRONT DRIVE SHAFT ASSEMBLY LH

HINT:

(See page DS-6)

3. REMOVE FRONT DRIVE SHAFT ASSEMBLY RH

HINT:

(See page DS-6)

4. REMOVE TRANSMISSION CONTROL CABLE CLAMP

(a) Remove the bolt and the transmission control cable

cla ...

Customizing vehicle features

Changing using the audio system screen

Audio system with “CAR” button

Press the “SETUP” button.

Select “Vehicle” on the “Setup” screen.

Audio system with “APPS” button

Press the “APPS” button.

Select “Setup” on the “Apps” screen and select †...