Toyota Sienna Service Manual: Disassembly

1. INSPECT UNDERDRIVE PLANETARY GEAR PRELOAD

HINT: (See page AX-260)

2. REMOVE FRONT PLANETARY GEAR NUT

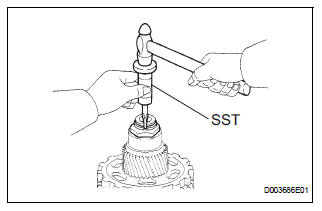

(a) Using SST, loosen the staked part of the lock nut.

SST 09930-00010 (09931-00010, 09931-00020), 09387-00050

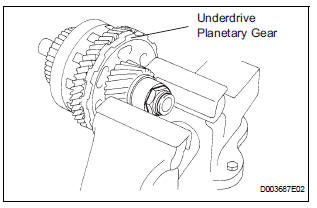

(b) Place the underdrive planetary gear in a soft jaw vise.

NOTICE: Be careful not to damage the differential drive pinion.

(c) Using a socket wrench, remove the lock nut.

3. REMOVE CYLINDRICAL ROLLER BEARING RACE INNER

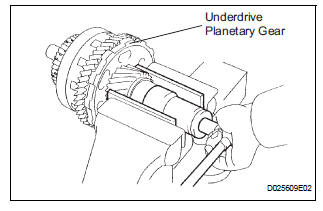

(a) Using SST, remove the cylindrical roller bearing race inner.

SST 09950-00020, 09950-00030, 09950-60010 (09951-00320, 09957-04010)

4. REMOVE UNDERDRIVE PLANETARY GEAR ASSEMBLY

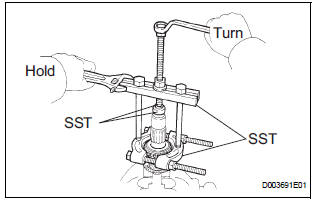

(a) Using SST and a press, remove the differential drive pinion, parking lock gear, counter driven gear with underdrive planetary ring gear and radial ball bearing front.

SST 09950-60010 (09951-00320), 09387-00050, 09950-00020, 09950-00030, 09950-40011 (09957-04010)

(b) Place the underdrive planetary gear in a soft jaw vise.

(c) Using SST, remove the radial ball bearing rear from the underdrive planetary gear

SST 09950-60010 (09951-00320), 09950-00030, 09950-40011 (09957-04010)

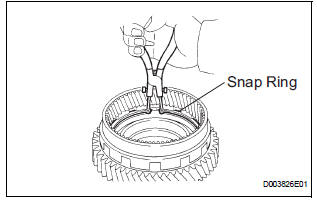

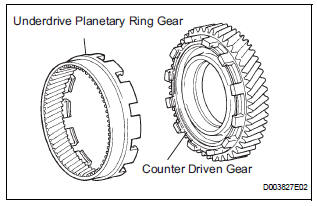

5. REMOVE UNDERDRIVE PLANETARY RING GEAR

(a) Using a snap ring pliers, remove the snap ring.

(b) Remove the underdrive planetary ring gear from the counter driven gear.

Underdrive planetary gear

Underdrive planetary gear

COMPONENTS

...

Inspection

Inspection

1. INSPECT UNDERDRIVE PLANETARY GEAR PRELOAD

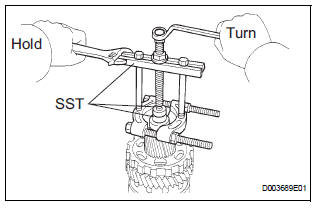

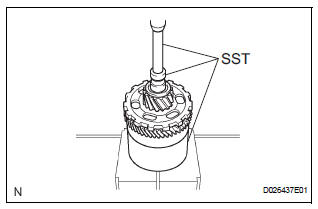

(a) Using SST, fix the underdrive planetary gear

assembly.

SST 09387-00050

(b) Using SST and a torque wrench, measure the

turning torque of th ...

Other materials:

Disposal

HINT:

The tire pressure warning valve and transmitter is powered

by a lithium battery. When disposing of the tire pressure

warning valve and transmitter, remove the battery and

dispose of it correctly.

1. DISPOSE OF TIRE PRESSURE WARNING VALVE AND TRANSMITTER

(a) Use the tip of a screwdriv ...

Disassembly

1. REMOVE RADIATOR WATER INLET

(a) Remove the 2 bolts and radiator water inlet.

2. REMOVE DRAIN PLUG

(a) Remove the drain plug and air drain plug.

(b) Remove the 2 O-rings.

3. REMOVE LOWER RADIATOR TANK

(a) Install the claw to the overhaul handle, inserting it in

the hole in Part A ...

Adjustment

HINT:

If the malfunction does not disappear by following the

procedure in ADJUSTMENT and the rear No. 2 seat

assembly needs to be replaced, do not disassemble the rear

No. 2 seat assembly.

1. ADJUST FRONT LEG

HINT:

Perform the following procedure if the inner leg does not

lock.

P ...