Toyota Sienna Service Manual: ECU Power Source Circuit

DESCRIPTION

The position control ECU and switch assembly (power seat control switch and ECU) is contained in the switch assembly.

During manual operation, only one switch signal is accepted. If signals are input from 2 or more switches simultaneously, all of them are ignored, except when signals are input from the front vertical switch and lifter switch simultaneously. In this case, the signal from the lifter will operate.

During automatic operation, a manual switch input will override any other operations, i.e. automatic operations will stop and the manual input operation only will be accepted. For example, if a manual switch input is activated during a seat store/restore operation, the previous operation will cease and manual operation will be performed. After the manual operation is performed, the previous automatic operation will not resume.

The power mirror store/restore operation is unaffected by manual switch inputs.

The front power seat switch does not allow the restore operation of the power seat when the system detects that the voltage of terminal SYSB is less than 8.0 +- 0.5 V for 30 msec. or is more than 10 +- 0.5 V for 30 msec.

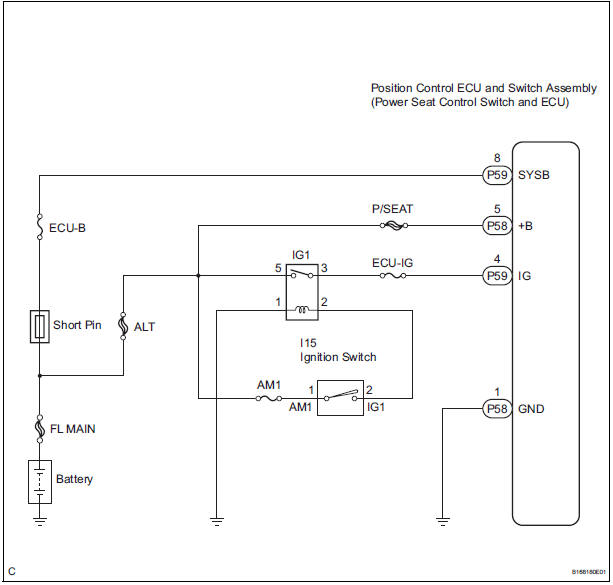

This circuit is the power source circuit for the position control ECU and switch assembly (power seat control switch and ECU).

HINT:

- Manual adjustment of the slide and reclining can be performed even when the front power seat switch is not functional if current is allowed to flow into terminals +B and SYSB.

- The lumber support function can always be used because its circuit does not include the ECU and differs from other functions (reclining, slide, lifter, and front vertical functions.)

WIRING DIAGRAM

INSPECTION PROCEDURE

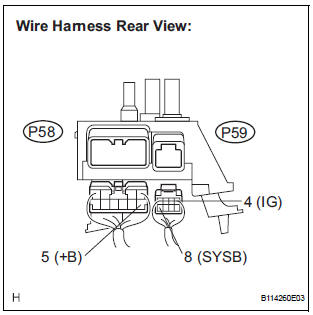

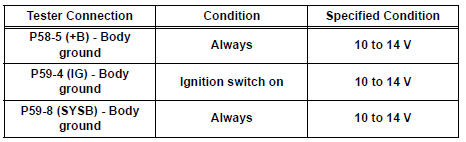

1 INSPECT POSITION CONTROL ECU AND SWITCH ASSEMBLY (POWER SEAT CONTROL SWITCH AND ECU POWER SOURCE CIRCUIT)

- Disconnect the position control ECU and switch assembly connectors.

- Measure the voltage according to the value(s) in the table below.

Standard voltage

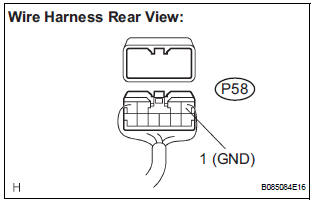

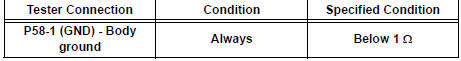

2 INSPECT POSITION CONTROL ECU AND SWITCH ASSEMBLY (POWER SEAT CONTROL SWITCH AND ECU GROUND CIRCUIT)

- Measure the resistance according to the value(s) in the table below.

Standard resistance

PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS TABLE

Driving Position Memory Switch Circuit (w/ Memory)

Driving Position Memory Switch Circuit (w/ Memory)

DESCRIPTION

The seat memory switch sends signals to the outer mirror control ECU LH via

the multiplex

communication system to memorize a given seat position. This memory system does

not use a po ...

Seat heater system

Seat heater system

PARTS LOCATION

...

Other materials:

System Too Lean/ System Too Rich

DTC P0171 System Too Lean (Bank 1)

DTC P0172 System Too Rich (Bank 1)

DTC P0174 System Too Lean (Bank 2)

DTC P0175 System Too Rich (Bank 2)

DESCRIPTION

The fuel trim is related to the feedback compensation value, not to the basic

injection time. The fuel trim

consists of both the short-term ...

Glove boxes

Upper glove box

Push the button.

Open the lid.

Lower glove box

The lower glove box can be opened by pulling the lever and can be

locked and unlocked by using the master key (vehicles without a

smart key) or the mechanical key (vehicles with a smart key system).

Unlo ...

Communication Error from Distance Control

ECU to ECM

DTC P1615 Communication Error from Distance Control

ECU to ECM

DTC U1101 Lost Communication with Distance Control

ECU

DESCRIPTION

The distance control ECU receives information about the area in front of the

vehicle from the laser sensor

and then sends a brake control demand signal (decelerat ...