Toyota Sienna Service Manual: Installation

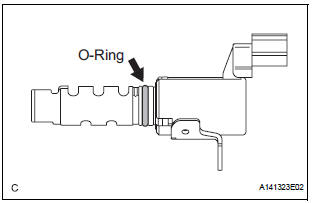

1. INSTALL CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY (for Bank 2 Exhaust Side)

- Apply a light coat of engine oil to the new O-ring and install it to the camshaft timing oil control valve.

- Install the camshaft timing oil control valve

assembly with the bolt.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

- Connect the camshaft timing oil control valve assembly connector

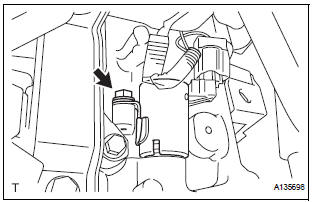

2. INSTALL CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY (for Bank 2 Intake Side)

- Apply a light coat of engine oil to the new O-ring and install it to the camshaft timing oil control valve.

- Install the camshaft timing oil control valve

assembly with the bolt.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf) Connect the camshaft timing oil control valve assembly connector

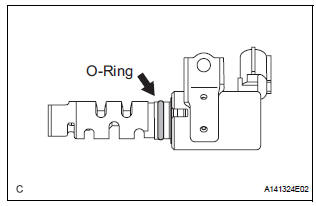

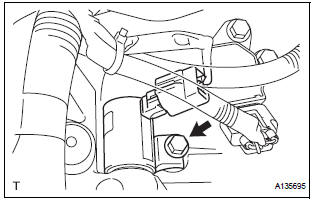

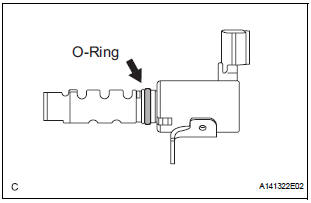

3. INSTALL CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY (for Bank 1 Exhaust Side)

- Apply a light coat of engine oil to the new O-ring and install it to the camshaft timing oil control valve.

- Install the camshaft timing oil control valve

assembly with the bolt.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

- Connect the camshaft timing oil control valve assembly connector

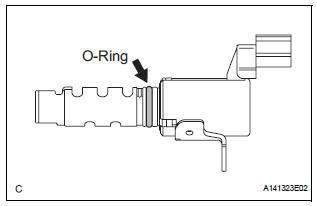

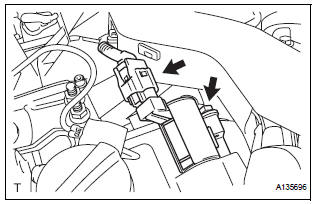

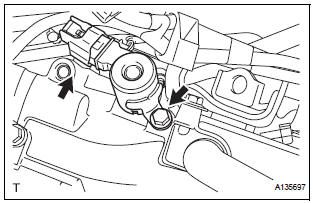

4. INSTALL CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY (for Bank 1 Intake Side)

- Apply a light coat of engine oil to the new O-ring and install it to the camshaft timing oil control valve.

- Install the camshaft timing oil control valve

assembly with the bolt.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

- Connect the camshaft timing oil control valve assembly connector.

5. INSTALL INTAKE AIR SURGE TANK ASSEMBLY

6. INSTALL AIR CLEANER CASE SUB-ASSEMBLY

7. INSTALL AIR CLEANER CAP SUB-ASSEMBLY

8. INSTALL NO. 1 AIR CLEANER INLET

9. INSTALL NO. 2 AIR CLEANER INLET

10. ADD ENGINE COOLANT

11. INSPECT FOR ENGINE COOLANT LEAK

12. INSPECT FOR ENGINE OIL LEAK

13. INSTALL V-BANK COVER SUB-ASSEMBLY

14. INSTALL FRONT OUTER COWL TOP PANEL SUBASSEMBLY

15. INSTALL WINDSHIELD WIPER MOTOR ASSEMBLY

Inspection

Inspection

1. INSPECT CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY

Resistance inspection

Using an ohmmeter, measure the resistance

between the terminals.

Resistance:

6.9 to 7.9 ] ...

Throttle body

Throttle body

...

Other materials:

Current Position Display does not Appear

INSPECTION PROCEDURE

1 CHECK RADIO AND NAVIGATION ASSEMBLY

Check if a map disc is inserted into the map disc slot.

OK:

A map disc is inserted

2 CHECK MAP DISC

Check that the map disc is not deformed or cracked.

OK:

No deformations or cracks appear on the map disc.

PROCEED ...

Disassembly

1. INSPECT UNDERDRIVE PLANETARY GEAR

PRELOAD

HINT:

(See page AX-260)

2. REMOVE FRONT PLANETARY GEAR NUT

(a) Using SST, loosen the staked part of the lock nut.

SST 09930-00010 (09931-00010, 09931-00020),

09387-00050

(b) Place the underdrive planetary gear in a soft jaw

vise.

NOTIC ...

Pressure Control Solenoid "D" Performance (Shift

Solenoid Valve SLT)

SYSTEM DESCRIPTION

The linear solenoid valve (SLT) controls the transmission line pressure for

smooth transmission operation

based on signals from the throttle position sensor and the vehicle speed sensor.

The ECM adjusts the

duty ratio (*) of the SLT solenoid valve to control hydraulic line ...