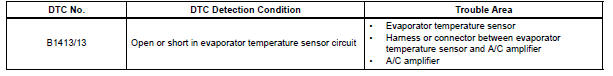

Toyota Sienna Service Manual: Evaporator temperature sensor circuit

DESCRIPTION

The evaporator temperature sensor (A/C thermistor) is installed on the evaporator in the air conditioning unit. It detects the temperature of the cooled air that has passed through the evaporator and its signal is used to control the air conditioning. It sends a signal to the A/C amplifier. The resistance of the evaporator temperature sensor (A/C thermistor) changes in accordance with the temperature of the cooled air that has passed through the evaporator. As the temperature decreases, the resistance increases. As the temperature increases, the resistance decreases.

The A/C amplifier applies voltage (5 V) to the evaporator temperature sensor

(A/C thermistor) and reads

voltage changes as the resistance of the evaporator temperature sensor (A/C

thermistor) changes. This

sensor is used to prevent the evaporator from freezing.

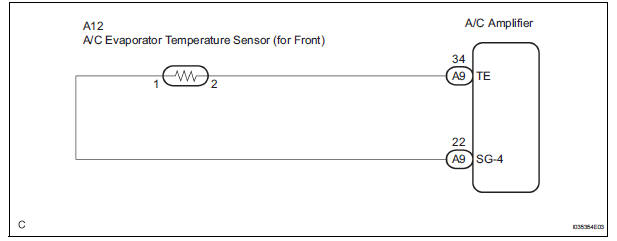

WIRING DIAGRAM

INSPECTION PROCEDURE

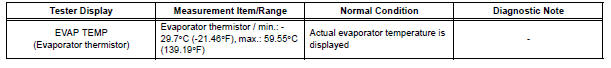

1 READ VALUE OF INTELLIGENT TESTER

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the intelligent tester main switch on.

(c) Select the item below in the DATA LIST, and read the display on the intelligent tester.

DATA LIST / AIR CONDITIONER:

OK: The display is as specified in the normal condition column.

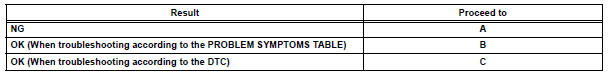

Result

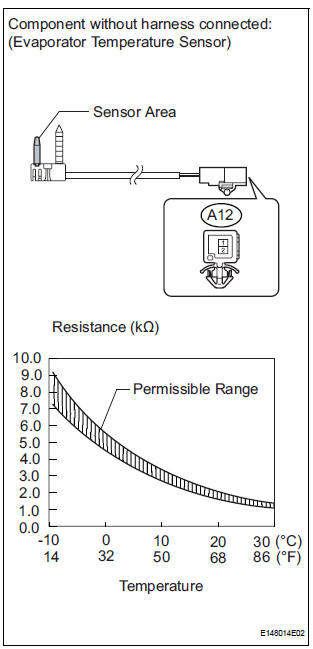

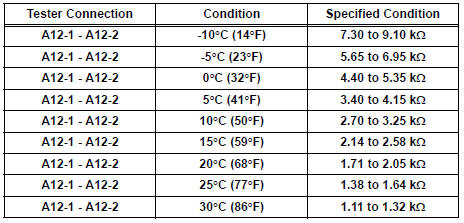

2 INSPECT EVAPORATOR TEMPERATURE SENSOR

(a) Disconnect the connector from the evaporator temperature sensor.

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

NOTICE:

- Even slightly touching the sensor may change the resistance value. Be sure to hold the connector of the sensor.

- When measuring, the sensor temperature must be the same as the evaporator temperature.

HINT: As the temperature increases, the resistance decreases (see the graph).

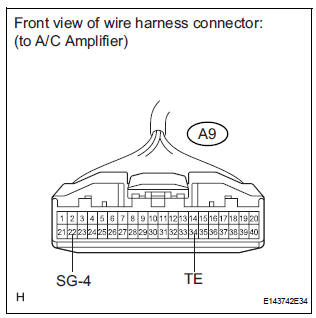

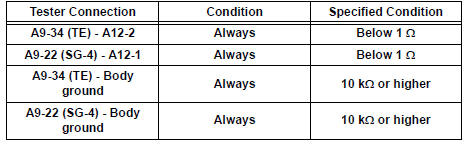

3 CHECK HARNESS AND CONNECTOR (EVAPORATOR TEMPERATURE SENSOR - A/C AMPLIFIER)

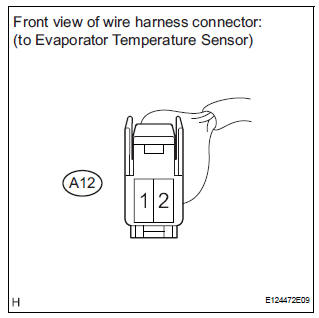

(a) Disconnect the evaporator temperature sensor connector.

(b) Disconnect the A/C amplifier connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard resistance

REPLACE A/C AMPLIFIER

Ambient temperature sensor circuit

Ambient temperature sensor circuit

DTC B1412/12 Ambient Temperature Sensor Circuit

DESCRIPTION

The ambient temperature sensor is installed in front of the condenser to

detect the ambient temperature

which is used to control the ai ...

Rear evaporator temperature sensor circuit

Rear evaporator temperature sensor circuit

DESCRIPTION

The rear evaporator temperature sensor is installed on the rear evaporator.

It detects the rear evaporator

temperature. The sensor sends a signal to the A/C amplifier. The resistance o ...

Other materials:

Audio system types

Entune Audio

Entune Audio Plus/Entune Premium Audio with Navigation

Owners of models equipped with a navigation system should refer to

the “NAVIGATION AND MULTIMEDIA SYSTEM OWNER’S

MANUAL”.

Using cellular phones

Interference may be heard through the audio system’s speakers if a c ...

Short in Front Passenger Side Squib Circuit

DTC B0105/53 Short in Front Passenger Side Squib Circuit

DESCRIPTION

The front passenger side squib circuit consists of the center airbag sensor

assembly and the front

passenger airbag assembly.

The circuit instructs the SRS to deploy when deployment conditions are met.

DTC B0105/53 is re ...

Trouble in Passenger Airbag ON / OFF Indicator

DESCRIPTION

The occupant classification system detects the front passenger seat

condition. It then informs a

passenger of the front passenger airbag, the front seat side airbag RH and front

seat belt pretensioner

RH condition (activated/not activated) by the passenger airbag ON/OFF indicator. ...