Toyota Sienna Service Manual: Inspection

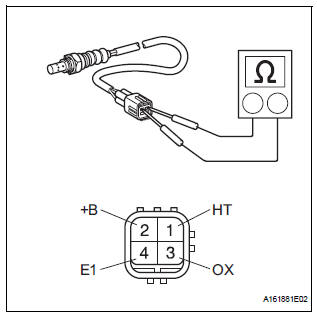

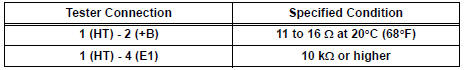

1. INSPECT HEATED OXYGEN SENSOR (for Bank 1 Sensor 2)

(a) Measure the resistance of the sensor.

Standard resistance

If the resistance is not as specified, replace the sensor.

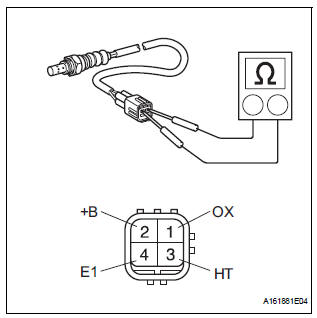

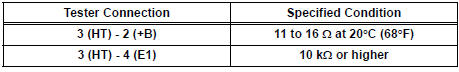

2. INSPECT HEATED OXYGEN SENSOR (for Bank 2 Sensor 2)

(a) Measure the resistance of the sensor.

Standard resistance

If the resistance is not as specified, replace the sensor.

Installation

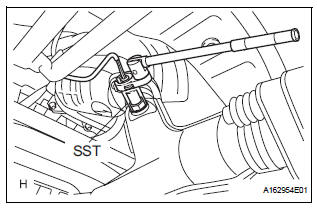

1. INSTALL HEATED OXYGEN SENSOR (for Bank 2 Sensor 2)

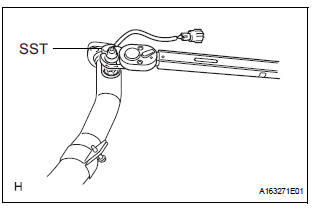

(a) Using SST, install the heated oxygen sensor to the front exhaust pipe.

SST 09224-00010

Torque: 40 N*m (408 kgf*cm, 30 ft.*lbf) for use with SST 44 N*m (449 kgf*cm, 32 ft.*lbf) for use without SST

HINT:

- Use a torque wrench with a fulcrum length of 30 cm (11.81 in.).

- Make sure that SST and a wrench are connected in a straight line.

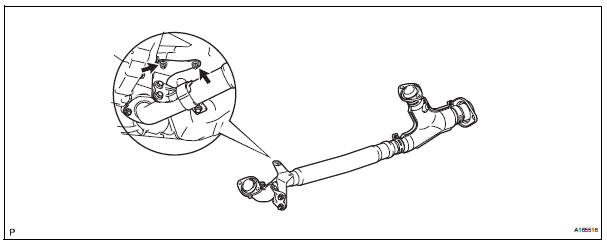

2. INSTALL FRONT EXHAUST PIPE ASSEMBLY

(a) Check the compression springs.

(1) Check the compression springs using vernier calipers

Specified length: 38.86 mm (1.5299 in.)

HINT: If the result is not as specified, replace the compression spring.

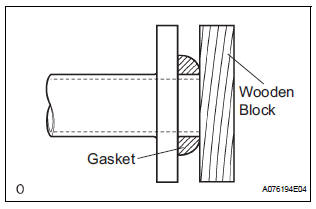

(b) Install the gasket.

(1) Install a new gasket by hand onto the front exhaust pipe assembly.

(2) Using a plastic hammer and wooden block, tap in the new gasket until its surface is flush with the front exhaust pipe.

NOTICE:

|

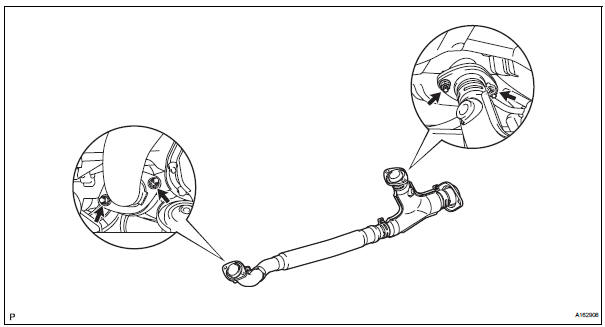

(c) Install 2 new gaskets to the front exhaust pipe assembly.

(d) Install the front exhaust pipe assembly with the 4 nuts.

Torque: 62 N*m (632 kgf*cm, 46 ft.*lbf)

(e) Install the front exhaust pipe assembly with the 2 compression springs and 2 bolts.

Torque: 43 N*m (438 kgf*cm, 32 ft.*lbf) (f) Install the No. 1 exhaust pipe support bracket with 2 new nuts.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

(g) Connect the heated oxygen sensor (for Bank 2 sensor 2) connector.

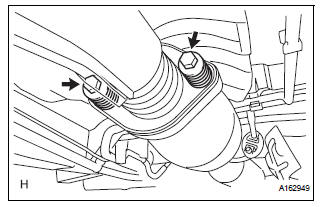

3. INSTALL HEATED OXYGEN SENSOR (for Bank 1 Sensor 2)

(a) Using SST, install the heated oxygen sensor.

SST 09224-00010

Torque: 40 N*m (408 kgf*cm, 30 ft.*lbf) for use with SST

44 N*m (449 kgf*cm, 32 ft.*lbf) for use without SST

HINT:

- Use a torque wrench with a fulcrum length of 30 cm (11.81 in.).

- Make sure that SST and a wrench are connected in a straight line.

b) Connect the heated oxygen sensor (for Bank 1 Sensor 2) connector.

4. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

5. INSPECT FOR EXHAUST GAS LEAK

Heated oxygen sensor (for 2wd)

Heated oxygen sensor (for 2wd)

Components

Removal

1. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the

cable from the nagative (-) battery terminal to

...

Heated oxygen sensor (for 4wd)

Heated oxygen sensor (for 4wd)

Components

...

Other materials:

On-vehicle inspection

1. INSPECT REAR AXLE HUB BEARING BACKLASH

(a) Using a dial gauge, check for backlash near the

center of the axle hub.

Maximum:

0.05 mm (0.0020 in.)

If backlash exceeds the maximum, replace the axle

hub assembly.

NOTICE:

Ensure that the dial gauge is set at right angles

to the measuremen ...

Torque converter clutch and drive plate

Inspection

1. Inspect torque converter clutch assembly

(a) Inspect the one-way clutch.

(1) Set SST into the inner race of the one-way

clutch.

SST 09350-32014 (09351-32010)

(2) Install SST so that it fits in the notch of the

converter hub and outer race of the one-way

clutch.

SST 0 ...

Removal

1. DISCONNECT BATTERY NEGATIVE TERMINAL

2. REMOVE FRONT DOOR SCUFF PLATE LH

3. REMOVE COWL SIDE TRIM BOARD LH

4. REMOVE INSTRUMENT PANEL FINISH PANEL SUBASSEMBLY

LOWER LH (See page IP-6)

5. REMOVE REAR DOOR SCUFF PLATE RH

6. REMOVE REAR DOOR SCUFF PLATE LH

7. REMOVE FRONT SEAT ASSEMBLY LH

HI ...