Toyota Sienna Service Manual: Inspection

1. Inspect no. 3 Intake air control valve assembly

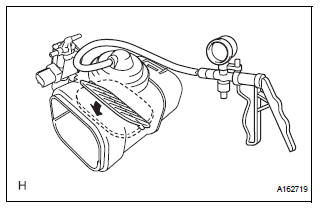

(A) inspect actuator operation.

(1) With 26.7 Kpa (200 mm hg, 7.9 In. Hg) of vacuum applied to the actuator, check that the actuator rod moves.

(2) One minute after applying the vacuum, check that the actuator rod does not return.

(3) If the operation is not as specified, replace the no. 3 Intake air control valve.

Installation

1. INSTALL NO. 3 INTAKE AIR CONTROL VALVE ASSEMBLY

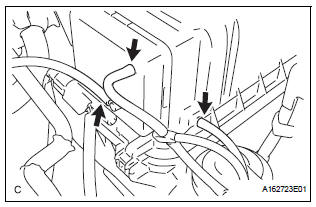

(a) Engage the 2 claws and install the No. 3 intake air control valve assembly.

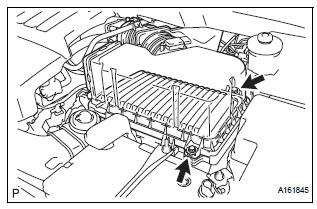

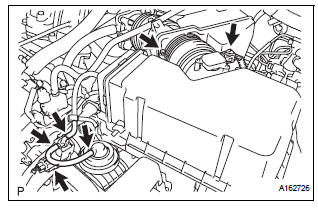

2. INSTALL AIR CLEANER CAP SUB-ASSEMBLY

(a) Install the air cleaner filter element, and air cleaner cap sub-assembly with the 2 bolts.

Torque: 5.0 N*m (50 kgf*cm, 44 in.*lbf)

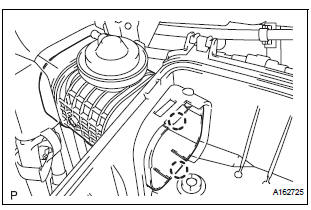

(b) Connect the 3 vacuum hoses.

(c) Tighten the bolt, connect the 2 connectors, and install the 2 vacuum hoses.

3. INSTALL NO. 2 AIR CLEANER INLET (See page EM- 60)

Removal

Removal

1. Remove no. 2 Air cleaner inlet (see page em-

28)

2. Remove air cleaner cap sub-assembly

(a) Disconnect the 3 vacuum hoses.

(b) Loosen the bolt, disconnect the 2 connectors, and

remove ...

Vacuum tank

Vacuum tank

On-vehicle inspection

1. Inspect air cleaner cap sub-assembly

(A) check that air flows from port b to port a.

(B) apply 60 kpa (450 mm hg, 18 in. Hg) of vacuum to

port b. Check that there is ...

Other materials:

CD Abnormal/ Excess Current/ Tray Insertion / Ejection Error/ CD Abnormal/

Excess Current/ Tray Insertion / Ejection Error

DTC 62-44 CD Abnormal

DTC 62-48 Excess Current

DTC 62-50 Tray Insertion / Ejection Error

DTC 63-44 CD Abnormal

DTC 63-48 Excess Current

DTC 63-50 Tray Insertion / Ejection Error

DESCRIPTION

DTC No.

DTC Detecting Condition

Trouble Area

62-44

Operation error ...

Starting the engine

Shift the shift lever to P and apply the brakes.

Touch the Toyota emblem side

of the electronic key to the

engine switch.

An alarm will sound to indicate that

the start function cannot detect the

electronic key that is touched to the

engine switch if any of the doors is

opened ...

How to proceed with

troubleshooting

1 VEHICLE BROUGHT TO WORKSHOP

2 CUSTOMER PROBLEM ANALYSIS

Interview the customer and confirm the trouble.

Confirm the problem by duplicating the conditions

described by the customer

3 BASIC INSPECTION

Basic inspection.

Measure the battery voltage.

Standard voltage:

11 ...