Toyota Sienna Service Manual: Disassembly

1. REMOVE GENERATOR CLUTCH PULLEY

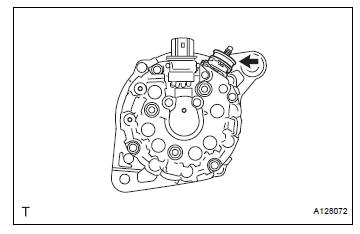

(A) using a screwdriver, remove the generator pulley cap.

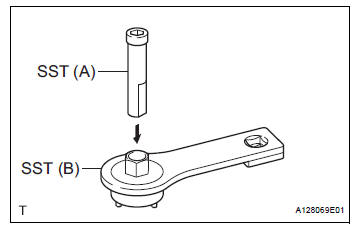

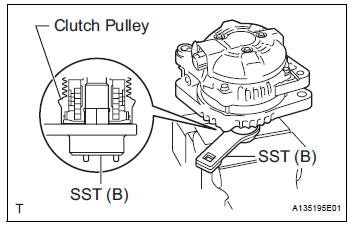

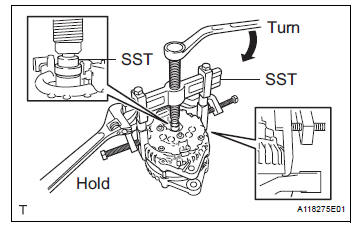

(b) Set SST (A) and (B).

SST 09820-63020

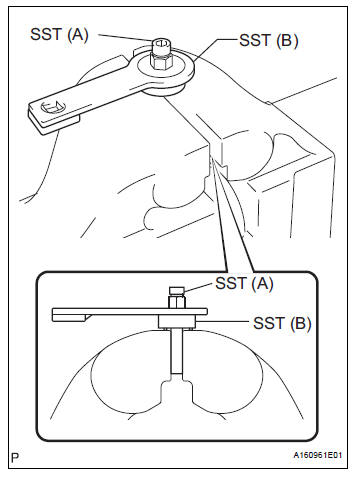

(c) Clamp SST (A) in a vise.

| NOTICE: Be sure to fix the flat surface of SST (A) in a vise. |

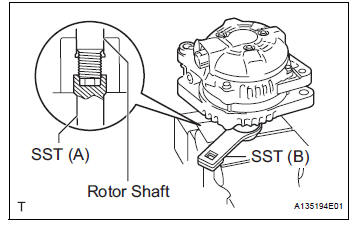

(d) Place the rotor shaft end into SST (A).

(e) Fit SST (B) to the clutch pulley.

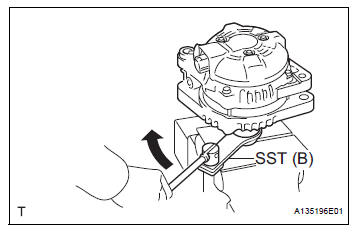

(f) Loosen the pulley by turning SST (B) in the direction shown in the illustration.

| NOTICE: Hold the generator assembly tightly. |

(g) Remove the generator assembly from SST.

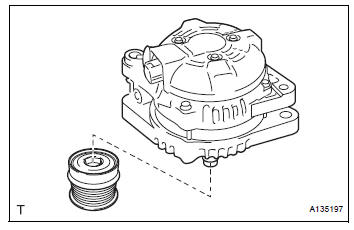

(h) Remove the clutch pulley from the rotor shaft.

2. REMOVE GENERATOR REAR END COVER

(a) Place the generator assembly on the clutch pulley.

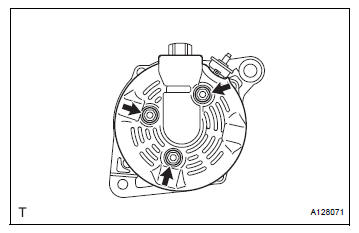

(b) Remove the 3 nuts and generator rear end cover.

3. REMOVE GENERATOR TERMINAL INSULATOR

(a) Remove the terminal insulator from the generator coil.

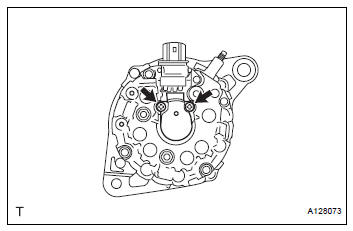

4. REMOVE GENERATOR BRUSH HOLDER ASSEMBLY

(a) Remove the 2 screws and brush holder from the generator coil.

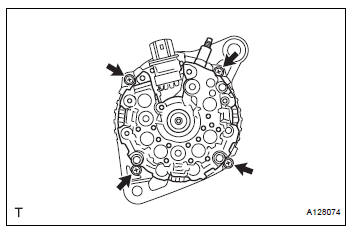

5. REMOVE GENERATOR COIL ASSEMBLY

(a) Remove the 4 bolts.

(b) Using SST, remove the generator coil assembly.

SST 09950-40011 (09951-04020, 09952-04010, 09953-04020, 09954-04010, 09955-04071, 09957-04010, 09958-04011)

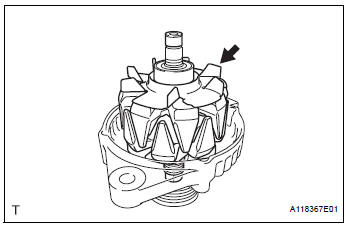

6. REMOVE GENERATOR ROTOR ASSEMBLY

(a) Remove the generator washer.

(b) Remove the generator rotor assembly.

Removal

Removal

1. Remove v-bank cover sub-assembly (see

page em-28)

2. Remove front wheel rh

3. Remove no. 1 Engine under cover (see page

em-26)

4. Remove front fender apron seal rh (see

page em-26)

5. Drain ...

Inspection

Inspection

1. Inspect generator clutch pulley

(a) Hold the center of the pulley, and confirm that the

outer ring turns counterclockwise and does not turn

clockwise.

If the result is not as specified, r ...

Other materials:

Fuel Pump Primary Circuit

DESCRIPTION

This DTC is designed to detect a malfunction in the fuel pump (FUEL

PUMP) relay circuit. When the

system is normal, the battery voltage is applied to FPR terminal of the ECM

while the FUEL PUMP

relay is turned OFF. If the battery voltage is not applied to the FPR

ter ...

Air outlet control servo motor (for rear air conditioning system)

ON-VEHICLE INSPECTION

1. INSPECT REAR AIR OUTLET CONTROL SERVO

MOTOR

(a) Inspect servo motor operation.

(1) Connect the positive (+) lead from the battery

to terminal 4 and negative (-) lead to terminal 5,

then check that the arm turns to "FOOT" side

smoothly.

(2) Connect t ...

Reassembly

1. INSTALL INSTR PNL PASS L/DOOR AIR BAG

ASSEMBLY

2. INSTALL INSTRUMENT PANEL WIRE NO.2

3. INSTALL NAVIGATION ANTENNA ASSEMBLY

4. INSTALL ANTENNA CORD SUB-ASSEMBLY

5. INSTALL INSTRUMENT PANEL BOX DOOR SUBASSEMBLY

NO.2

6. INSTALL INSTRUMENT PANEL FINISH PANEL

RETAINER NO.1

7. INSTALL INSTRUM ...