Toyota Sienna Service Manual: Inspection

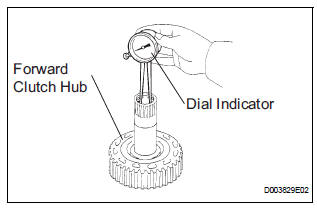

1. INSPECT MULTIPLE DISC CLUTCH HUB

(a) Using a dial indicator, measure the inside diameter of the forward clutch hub bushing

Standard inside diameter: 23.025 to 23.046 mm (0.9065 to 0.9073 in.) Maximum inside diameter: 23.09 mm (0.9091 in.)

| NOTICE: Check the contact surface of the bushing in the direct clutch shaft. If any scratch or discoloration is found, replace the direct clutch sub-assembly with a new one. |

If the inside diameter is greater than the maximum, replace the forward clutch hub with a new one.

2. INSPECT UNDERDRIVE CLUTCH DISC NO.2

(a) Check if the sliding surfaces of the disc, plate and flange are worn or burnt.

If necessary, replace them.

NOTICE:

|

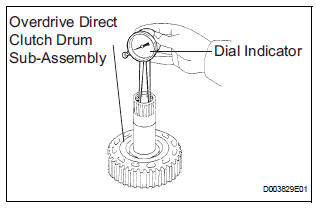

3. INSPECT OVERDRIVE DIRECT CLUTCH DRUM SUBASSEMBLY

(a) Using a dial indicator, measure the inside diameter of the forward clutch hub bushing.

Standard inside diameter: 23.025 to 23.046 mm (0.9065 to 0.9073 in.) Maximum inside diameter: 23.09 mm (0.9091 in.)

| NOTICE: Check the contact surface of the bushing in the direct clutch shaft. If any scratch or discoloration is found, replace the direct clutch sub-assembly with a new one. |

If the inside diameter is greater than the maximum, replace the forward clutch hub with a new one.

4. INSPECT 2ND BRAKE CLUTCH DISC

(a) Check if the sliding surface of the disc, plate and flange are worn or burnt.

If necessary, replace them.

NOTICE:

|

5. INSPECT 1ST AND REVERSE BRAKE CLUTCH DISC

(a) Check if the sliding surface of the disc, plate and flange are worn or burnt.

If necessary, replace them.

NOTICE:

|

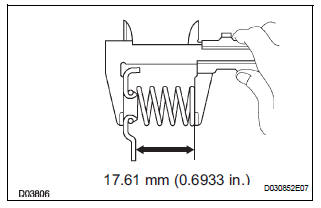

6. INSPECT 1ST AND REVERSE BRAKE RETURN SPRING SUB-ASSEMBLY

(a) Using a vernier calipers, measure the free length of the spring together with the spring seat.

Standard free length: 17.61 mm (0.6933 in.) HINT: If the result is not as specified, replace the spring.

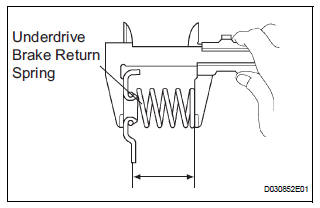

7. INSPECT UNDERDRIVE BRAKE RETURN SPRING SUB-ASSEMBLY

(a) Using a vernier calipers, measure the free length of the spring together with the spring seat.

Standard free length: 13.24 mm (0.5213 in.) HINT: If the result is not as specified, replace the spring.

8. INSPECT PACK CLEARANCE OF 1ST AND REVERSE BRAKE

(a) Using vernier calipers, measure the distance between the disc surface and the contact surface of the 2nd brake cylinder and transaxle case (Dimension A).

(b) Select an appropriate flange so that the pack clearance will meet the specified value.

Pack clearance: 1.16 to 1.35 mm (0.0457 to 0.0531 in.)

HINT: Piston stroke = Dimension A - Flange thickness

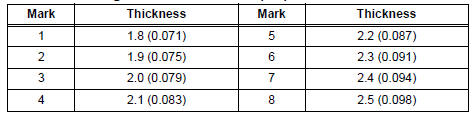

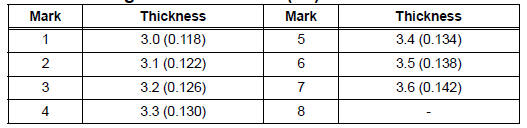

Flange thickness: mm (in.)

(c) Install the flange.

9. INSPECT PACK CLEARANCE OF 2ND BRAKE

(a) Using a vernier calipers, measure the distance between the disc surface and snap ring surface (Dimension B).

(b) Select an appropriate flange so that the pack clearance will meet the specified value.

Pack clearance: 0.62 to 0.91 mm (0.0244 to 0.0358 in.)

HINT: Piston stroke = Dimension B - Flange thickness - Snap ring thickness 1.6 mm (0.063 in.)

Flange thickness: mm (in.)

(c) Install the flange.

9. INSPECT PACK CLEARANCE OF 2ND BRAKE

(a) Using a vernier calipers, measure the distance between the disc surface and snap ring surface (Dimension B).

(b) Select an appropriate flange so that the pack clearance will meet the specified value.

Pack clearance: 0.62 to 0.91 mm (0.0244 to 0.0358 in.)

HINT: Piston stroke = Dimension B - Flange thickness - Snap ring thickness 1.6 mm (0.063 in.)

Flange thickness: mm (in.)

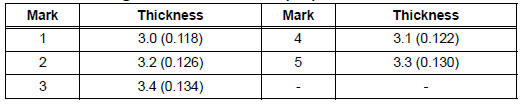

10. INSPECT PACK CLEARANCE OF UNDERDRIVE BRAKE

(a) Using a dial indicator, measure the underdrive brake pack clearance while applying and releasing compressed air (392 kPa, 4.0 kgf/cm2, 57 psi).

Pack clearance: 1.81 to 2.20 mm (0.0713 to 0.0866 in.)

HINT: Select an appropriate flange from the table below so that it will meet the specified value.

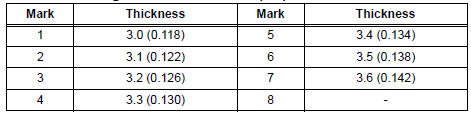

Flange thickness: mm (in.)

(b) Temporarily remove the snap ring and attach it to the flange.

(c) Reinstall the snap ring.

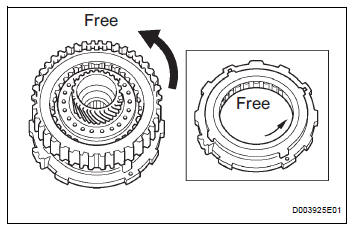

11. INSPECT UNDERDRIVE 1-WAY CLUTCH ASSEMBLY

(a) Install the underdrive clutch assembly to the 1-way clutch.

(b) Rotate the underdrive 1-way clutch assembly to check the rotating direction for the lock or free operation.

HINT: If the result is not as specified, replace the underdrive 1-way clutch.

12. INSPECT INPUT SHAFT END PLAY

(a) Using a dial indicator, measure the input shaft end play.

End play: 0.262 to 1.244 mm (0.01 to 0.049 in.)

HINT: If the result is not as specified, replace the input shaft or thrust needle roller bearing.

Disassembly

Disassembly

1. Remove park/neutral position switch assembly

(A) remove the nut, washer and control shaft lever.

(B) using a screwdriver, unstake the nut stopper, and

remove the lock nut and nut stopper ...

Reassembly

Reassembly

1. BEARING POSITION

2. INSTALL DIFFERENTIAL GEAR LUBE APPLY TUBE

(a) Install the differential gear lube apply tube and

transaxle apply tube clamp with the bolt to the

transaxle housing ...

Other materials:

Data list / active test

1. DATA LIST

HINT:

Reading the DATA LIST displayed on an intelligent tester

enables values, including those of the switches, sensors,

and actuators, to be checked without removing any

parts. Reading the DATA LIST as the first step in

troubleshooting is one method to shorten diagnostic

time.

...

Vehicle Speed Signal Circuit between Multi-display and Combination

Meter

DESCRIPTION

This circuit is necessary for the ASL (Auto Sound Leveliser) built into the

radio receiver.

Speed signals are received from the combination meter and used for the ASL.

The ASL function automatically adjusts the sound data in order to enable hearing

the clear audio sound

even ...

Diagnostic trouble code chart

COMMUNICATION DIAGNOSIS:

SW:

SW WITH NAME:

SW CONVERTING:

COMMAND SW:

FRONT MONITOR:

DVD PLAYER:

TELEPHONE:

NAVI:

IN-DASH CD CHANGER:

GPS:

CAMERA UNIT:

...