Toyota Sienna Service Manual: Installation

1. INSTALL REAR DRIVE SHAFT ASSEMBLY LH

(a) Install the drive shaft to the axle carrier.

NOTICE: Be careful not to damage the boot and ABS speed sensor rotor to the drive shaft and oil seal of the axle hub bearing.

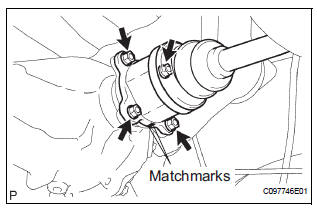

(b) Align the matchmarks and connect the drive shaft to the side gear shaft.

NOTICE: Be careful not to damage the boots and end cover.

(c) Install the drive shaft with the 4 nuts and washers.

Torque: 56 N*m (571 kgf*cm, 41 ft.*lbf)

2. INSTALL REAR AXLE SHAFT NUT

(a) Install a new axle shaft nut.

Torque: 216 N*m (2,200 kgf*cm, 159 ft.*lbf) (b) Using a chisel and hammer, stake the axle shaft nut.

3. INSTALL TAIL EXHAUST PIPE ASSEMBLY (See page EX-12)

4. INSTALL REAR SPEED SENSOR

(a) Install the speed sensor with the bolt.

Torque: 8.0 N*m (82 kgf*cm, 71 in.*lbf)

HINT:

- Be careful not to damage the speed sensor.

- Prevent foreign matter from adhering to the speed sensor.

- Do not twist the sensor wire when installing the sensor.

5. INSTALL REAR WHEEL Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

6. CHECK FOR EXHAUST GAS LEAK

7. CHECK ABS SPEED SENSOR SIGNAL

HINT:

- for ANTI-LOCK BRAKE SYSTEM: (See page BC-3)

- for VEHICLE STABILITY CONTROL SYSTEM: (See page BC-72)

Reassembly

Reassembly

1. INSTALL REAR DRIVE SHAFT OUTBOARD JOINT BOOT

HINT:

Before install the boot, wrap the spline of the outboard

joint shaft with vinyl tape to prevent the boot from

bearing damaged.

(a) Instal ...

Differential

Differential

...

Other materials:

Memory recall function

Each electronic key can be registered to recall your preferred driving

position.

Registering procedure

Record your driving position to button “1” or “2” before performing

the following:

Carry only the key you want to register, and then close the driver’s

door.

If 2 or more keys ar ...

Using the mechanical key (vehicles with a smart key system)

To take out the mechanical key,

push the release button and take

the key out.

The mechanical key can only be

inserted in one direction, as the

key only has grooves on one side.

If the key cannot be inserted in a

lock cylinder, turn it over and reattempt

to insert it.

After using t ...

Absence of Registration Unit/ No Response for Connection Check/ Last Mode

Error/ No Response Against ON / OFF Command/ Mode Status Error/ Slave Reset

DTC 01-D5 Absence of Registration Unit

DTC 01-D8 No Response for Connection Check

DTC 01-D9 Last Mode Error

DTC 01-DA No Response Against ON / OFF Command

DTC 01-DB Mode Status Error

DTC 01-DE Slave Reset

DESCRIPTION

HINT:

*1: Even if no fault is present, this trouble code may b ...