Toyota Sienna Service Manual: Reassembly

1. INSTALL REAR DRIVE SHAFT OUTBOARD JOINT BOOT

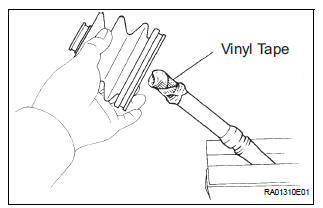

HINT: Before install the boot, wrap the spline of the outboard joint shaft with vinyl tape to prevent the boot from bearing damaged.

(a) Install new outboard joint boot, 2 outboard joint boot clamps, 2 inboard joint boot clamps and inboard joint boot.

(b) Make sure that the 2 boots are on the shaft groove.

2. INSTALL REAR DRIVE SHAFT OUTBOARD JOINT BOOT CLAMP

(a) Hold the drive shaft lightly in a soft vise.

(b) Install the 2 outboard joint boot clamps to the boot.

HINT: Before install the clamps, pack the outboard joint and boot with grease in the boot kit.

Grease capacity: 90 to 110 g (3.2 to 3.9 oz.)

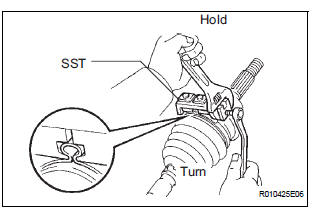

(c) Place SST onto the 2 outboard joint boot clamps.

SST 09521-24010

(d) Tighten the SST so that the 2 outboard joint boot clamps is pinched.

NOTICE: Do not overtighten the SST.

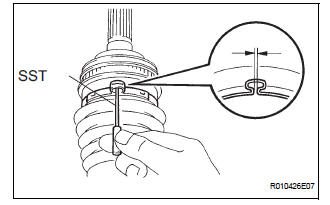

(e) Using a SST, measure the clearance of the 2 outboard joint boot clamps.

SST 09240-00020 Clearance: 1.2 to 4.0 mm (0.047 to 0.157 in.)

NOTICE: When the measured value is greater than the specified value, retighten the clamp.

3. INSTALL REAR DRIVE SHAFT INBOARD JOINT ASSEMBLY

(a) Through a new inboard joint boot, 2 new inboard joint clamps and cage.

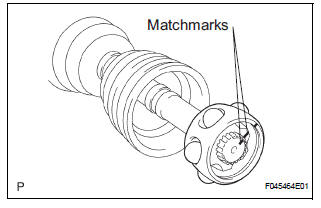

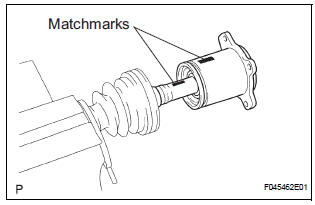

(b) Align the matchmarks, using a brass bar and a hammer, install the inner race.

(c) Using a snap ring expander, install a new rear drive shaft snap ring.

(d) Align the matchmarks, install the cage to the inner race.

(e) Install the 6 balls with grease to the inner race.

(f) Pack the inboard joint shaft and boot with grease in the boot kit.

Grease capacity: 130 to 150 g (4.6 to 5.3 oz.)

(g) Align the matchmarks, install the inboard joint assembly to the outboard joint shaft assembly.

(h) Install the clip.

4. INSTALL REAR DRIVE SHAFT INBOARD JOIN BOOT

(a) Install the inboard joint boot to the rear drive shaft inboard joint.

5. INSTALL REAR DRIVE SHAFT INBOARD JOINT BOOT CLAMP

(a) Using a screwdriver, install the No. 2 rear drive shaft inboard joint boot clamp.

(b) Install the inboard joint boot clamp by the same procedures as the No. 2 rear drive shaft inboard joint boot clamp.

Inspection

Inspection

1. INSPECT REAR DRIVE SHAFT ASSEMBLY LH

(a) Check that there is no remarkable play in the radial

direction of the outboard joint.

(b) Check that the inboard joint slides smoothly in the

thru ...

Installation

Installation

1. INSTALL REAR DRIVE SHAFT ASSEMBLY LH

(a) Install the drive shaft to the axle carrier.

NOTICE:

Be careful not to damage the boot and ABS

speed sensor rotor to the drive shaft and oil seal

o ...

Other materials:

Shift Solenoid "D" Control Circuit

DESCRIPTION

Shifting from 1st to 5th is performed in combination with "ON" and "OFF"

operation of the shift solenoid

valves SL1, SL2, SL3, S4 and SR which are controlled by the ECM. If an open or

short circuit occurs in

either of the shift solenoid valves, the ECM cont ...

Reassembly

1. INSTALL LIGHT CONTROL ECU (DISCHARGE HEADLIGHT)

Install a new headlight leveling motor base packing.

Install the headlight leveling motor assembly as

shown in the illustration.

Connect the connector with the claw

Install the light control ECU with the 2 ...

Mobile Assistant

The Mobile Assistant feature will activate Apple’s Siri® Eyes Free mode via

the steering wheel switches. To operate the Mobile Assistant, a compatible

cellular phone must be registered and connected to this system via Bluetooth®.

Press and hold the until

you hear the beeps

...